Aluminum die casting is the most common process used in diverse industries to produce aluminum casting parts since aluminum has excellent material flowability, high corrosion resistance, and high dimensional stability with complex parts shapes.

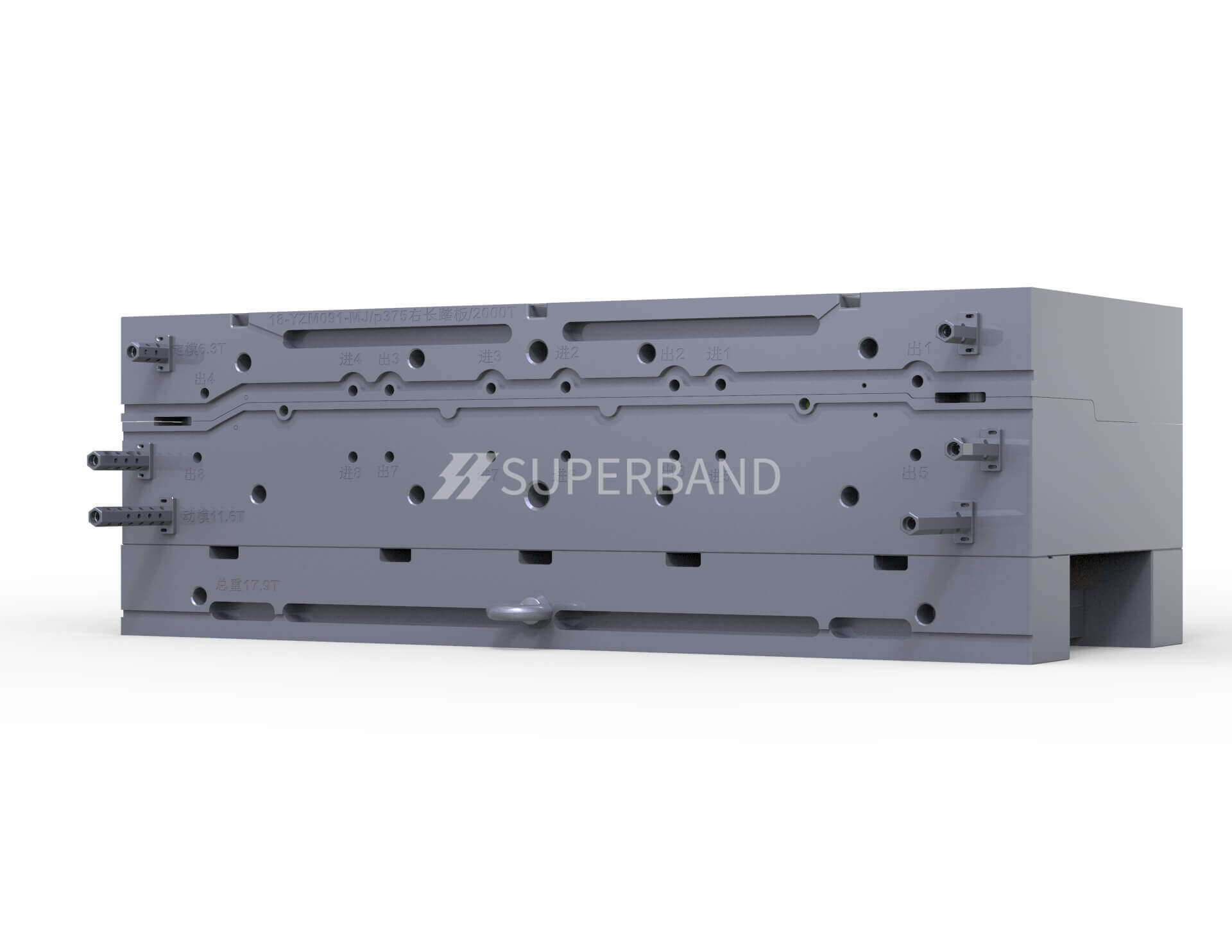

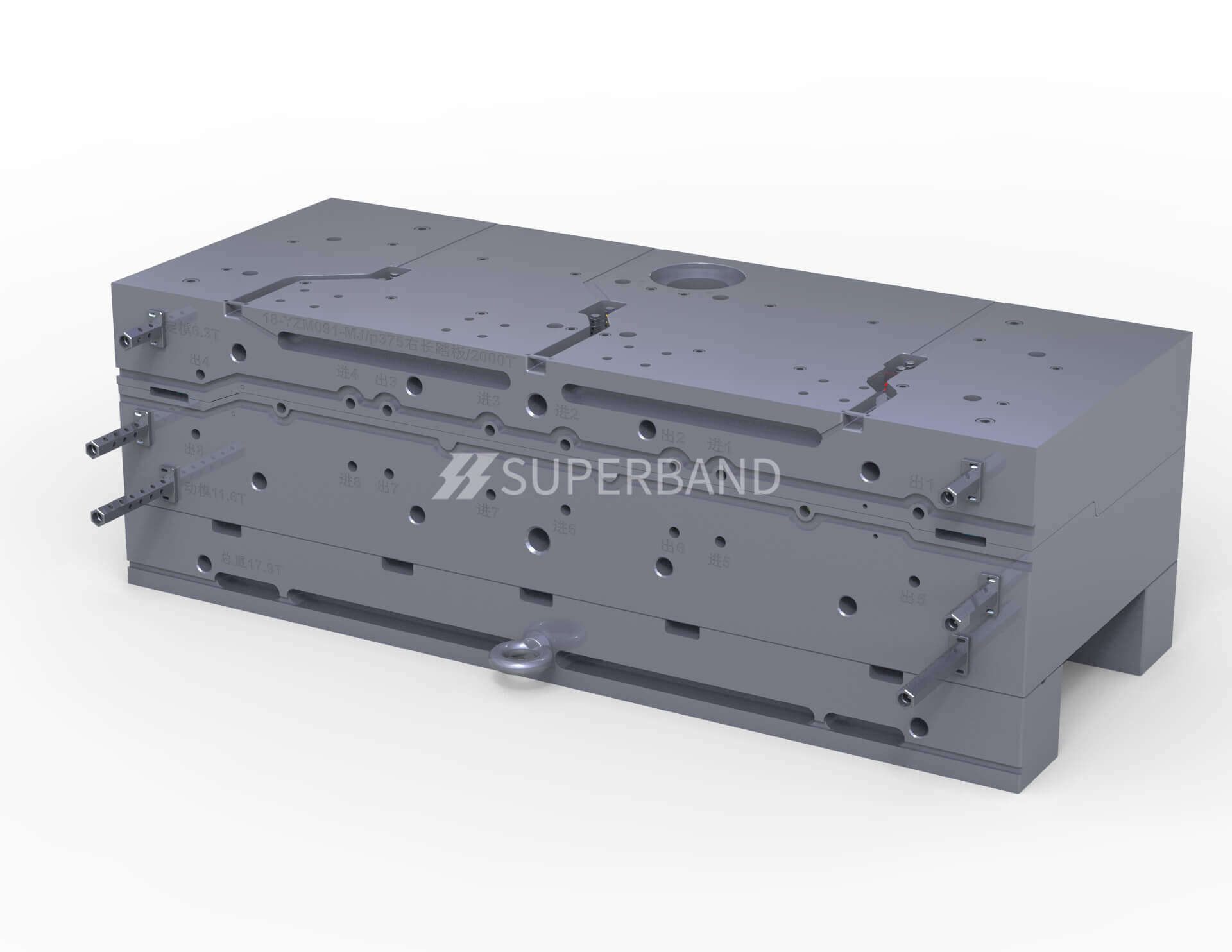

Superband die castings for automotive components are widely used, such as wheel hub molds, cylinder blocks, engine cylinder cover, knuckle, pistons, brake cylinders, and auto suspension molds.

Production design ,mould design , casting technology research, casting simulation ,mould manufacturing , mould technology service, material analysis , equipment matching , aluminum alloy die castings

1pcsDMD high-speed machining center , 2pcs MAKINO high-speed machining center , 38pcs CNC / graphite machining center , 10pcs linear cutting machine , 10pcs EDM , 2pcs Die spotting machine , 1pcs punching machine ,1pcs five-axis machining center.

1. Customer Provide Drawing Or Sample

2. DFM

3. Mold Flow Analysis

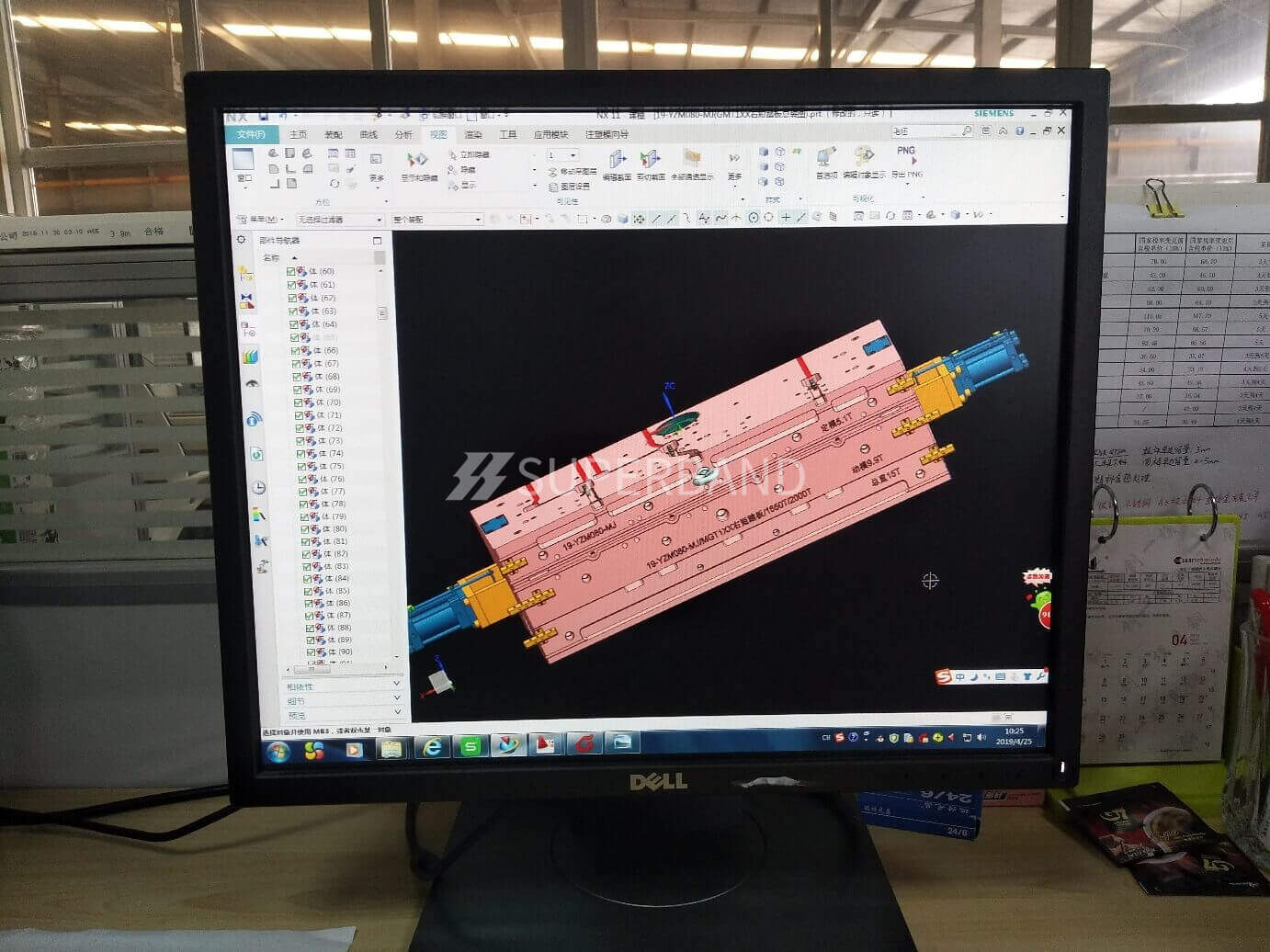

4. Mold 3D Design

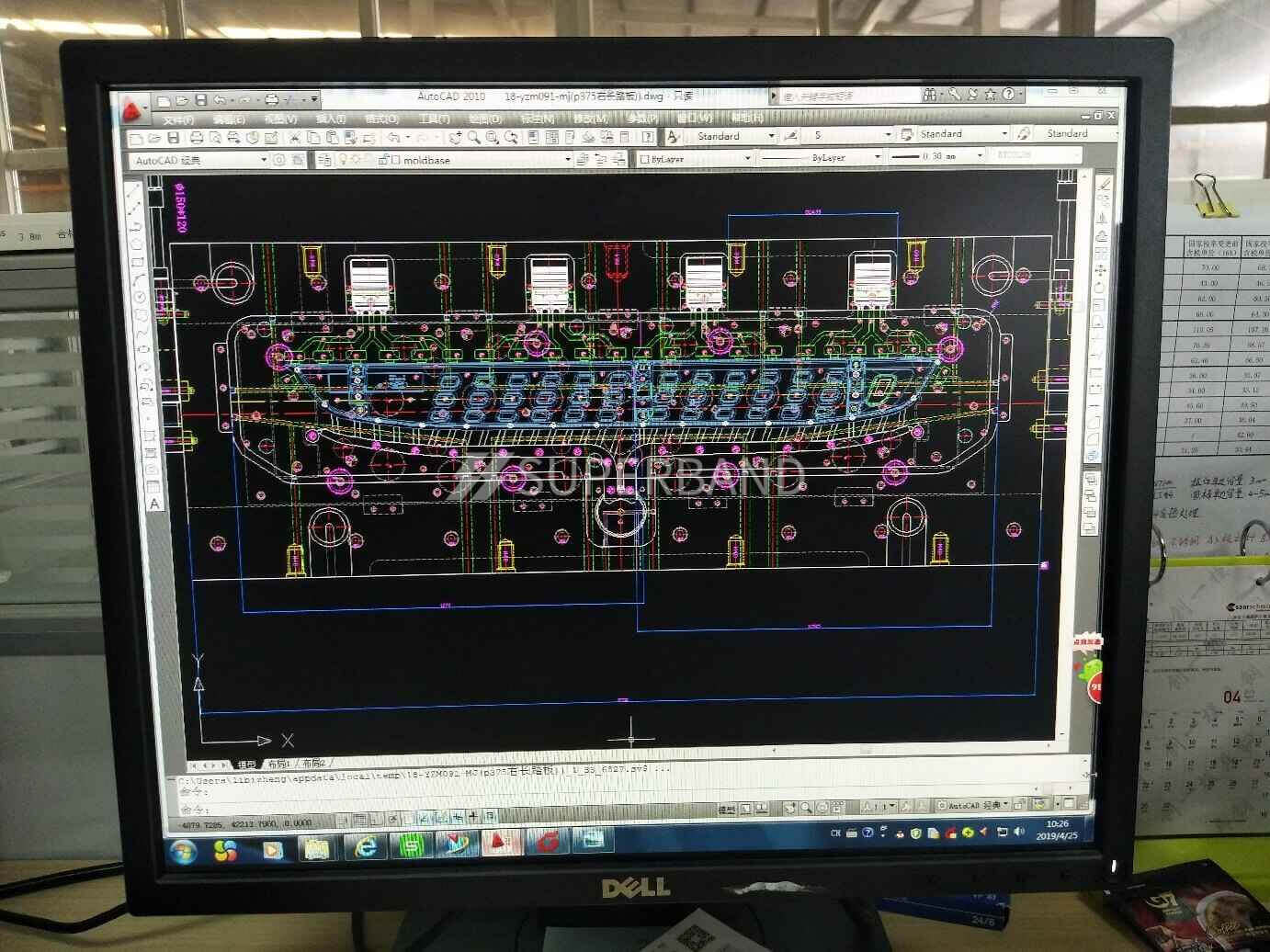

5. 2D Design

6. Prepare Mold Material

7. Wire-cutting

8. CNC

9. EDM

10. Mold Polish

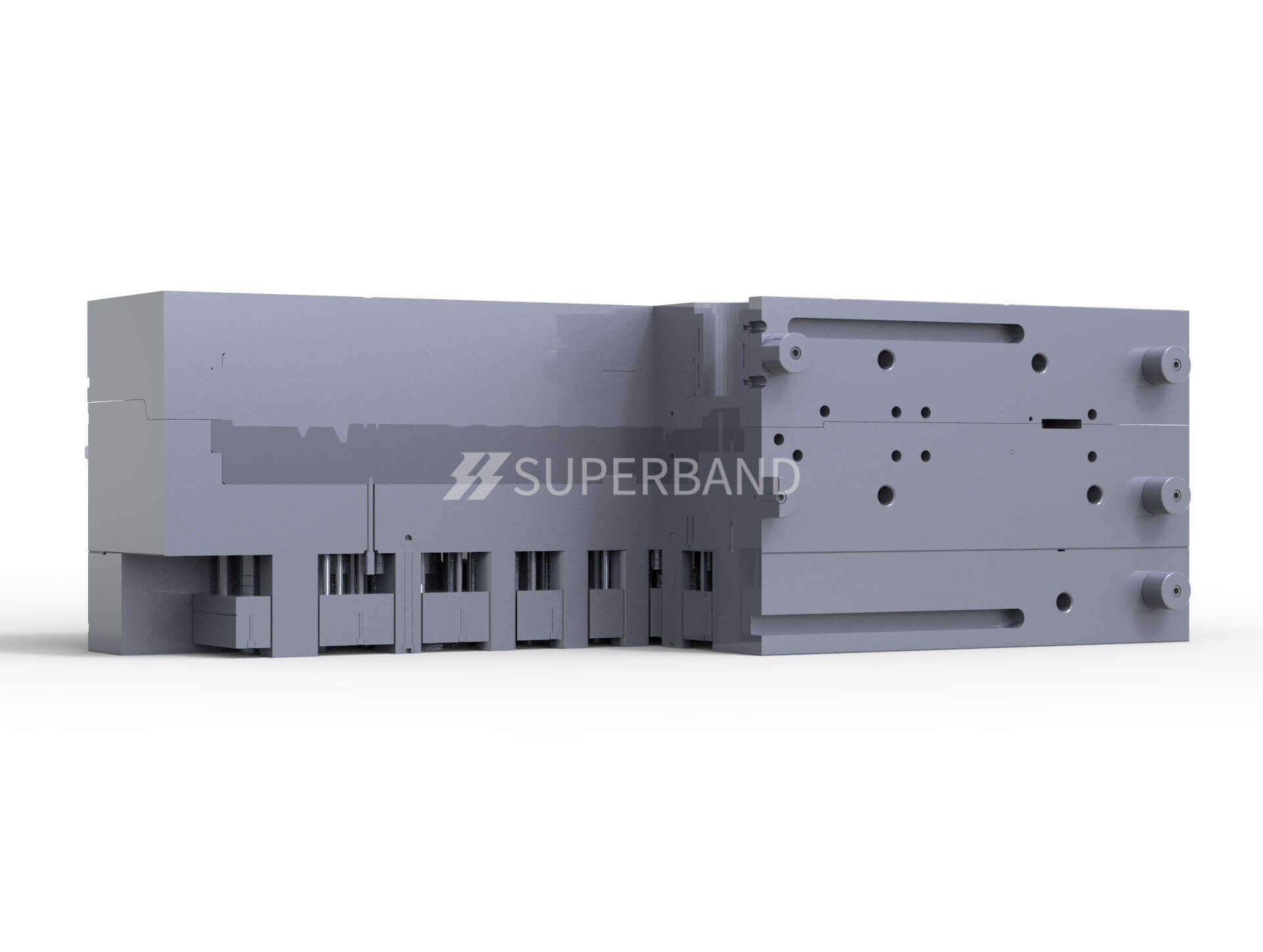

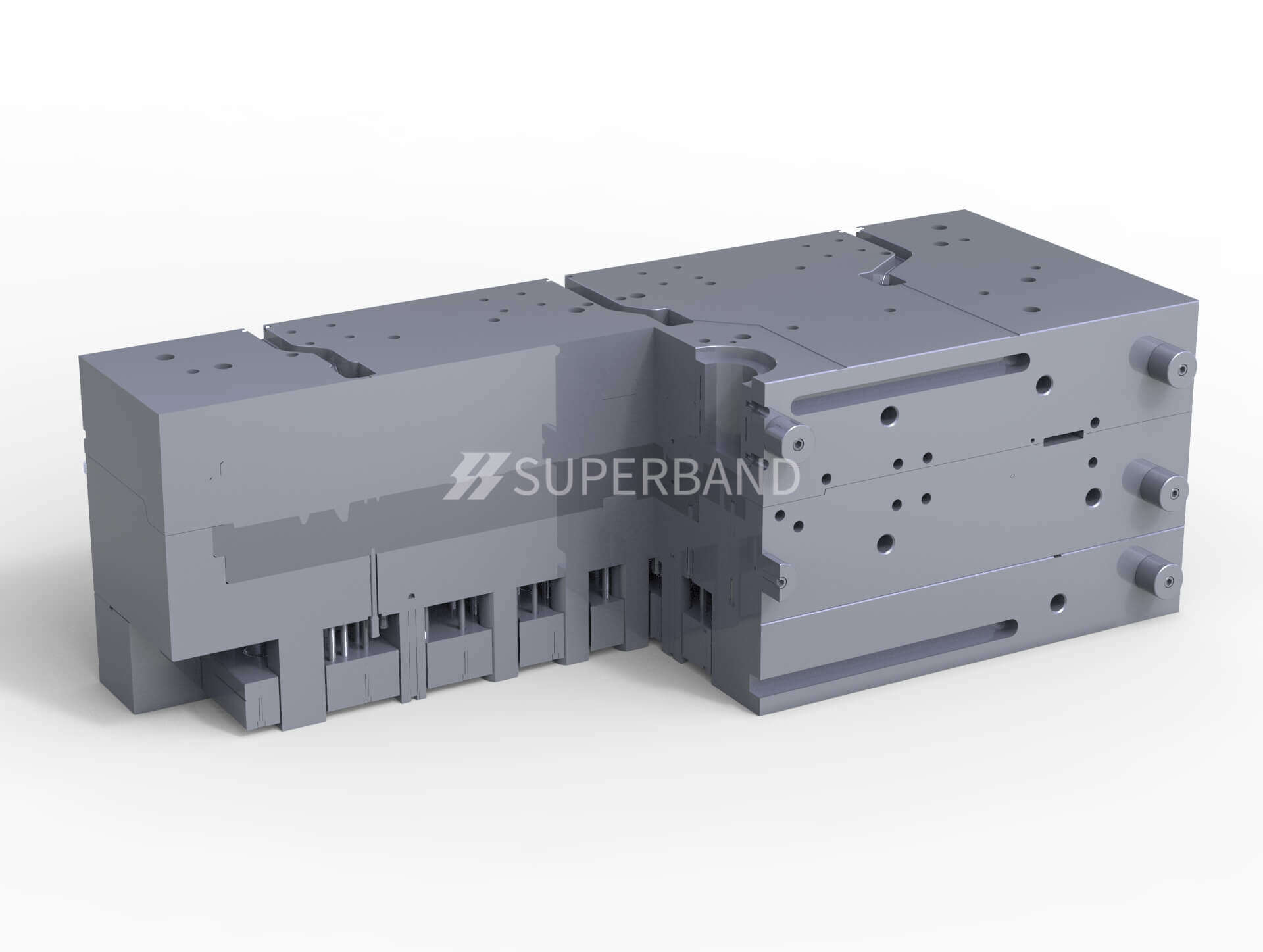

11. Assembly

12. Mlod Trial & Sampling