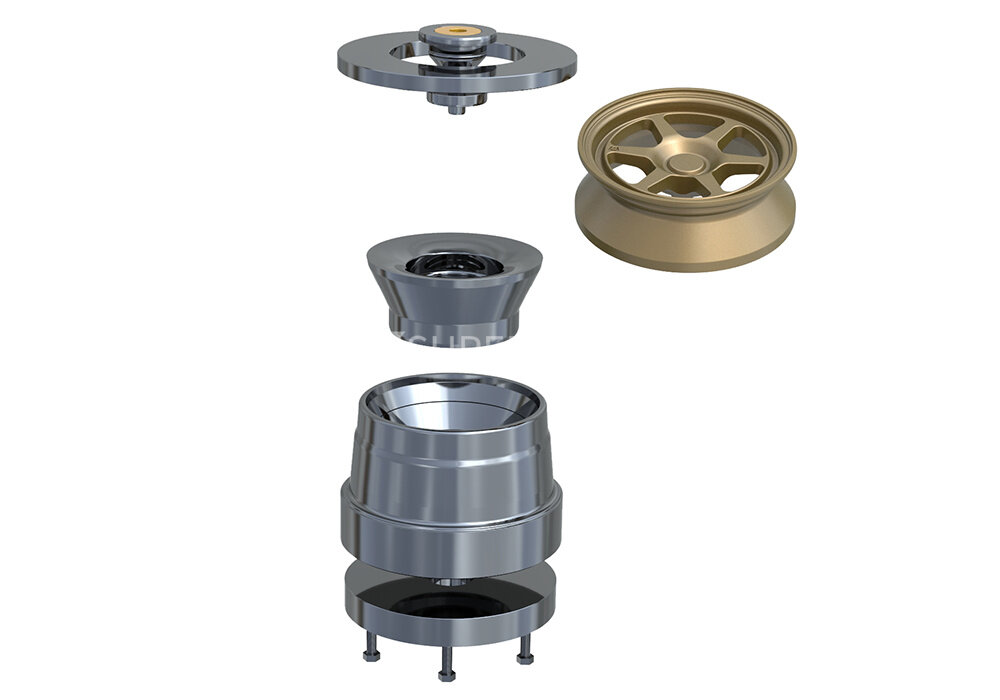

Wheel technology is mainly divided into casting and forging. Flow forming aluminum auto wheel molding belongs to casting - a manufacturing technology in which molten metal is poured or forced into a mold's cavity. Aluminum alloy is the most commonly used die-casting material, while casting allows each component to be created with accuracy and repeatability. So, flow form molds feature higher strength and better toughness than gravity wheel molds and low pressure wheel molds.

Hot tag: OEM wheel molds, auto wheel hub tooling, leading aluminum alloy mold maker, casting wheel mold, flow form molds suppliers, flow form molds design, flow forming mold making

| Equipment Name | QTY |

| DMG/MAKINO High-speed Machining Center | 3 |

| Machining Centr /High Speed CNC Machining Center | 52 |

| Five-axis Machining Center | 1 |

| EDM | 10 |

| Lathe | 28 |

| Hydraulic Tipping Crucible Furnace | 1 |

| Holding Furnance | 1 |

| Heat Treatment Furnace | 2 |

| Vacuum High Pressure Gas Quenching Furnance | 1 |

| Tempering Furnace | 4 |

| Gas Nitriding Furnace | 1 |

| Gas Carburizing Furnace | 2 |

| CMM | 3 |

| Die Spotting Machine | 2 |

| Sand-Blasting Machine | 1 |

| Milling Machine | 20 |

| Welding Machine | 18 |

| Laser cutting Machine/Wire Cutting Machine /Machine Tool | 11 |

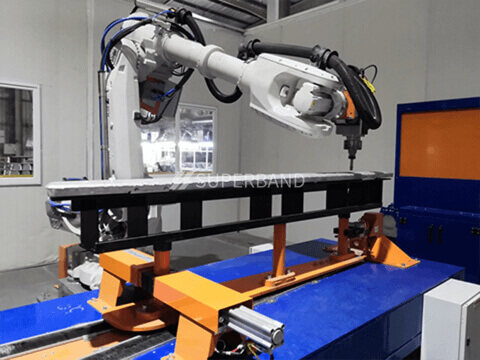

| Welding Robot System | 2 |

| Metallographic Detector | 1 |

| Hardness Tester | 1 |

Elevate your automotive wheel manufacturing process with our meticulously crafted Flow Forming Casting Aluminum Auto Wheel Mold. Engineered with precision and durability in mind, our mold offers unparalleled performance to meet the demanding standards of the automotive industry.

Advanced Flow Forming Technology: Our mold integrates cutting-edge flow forming technology, ensuring superior strength, reduced weight, and enhanced performance in automotive wheels.

High-Quality Aluminum Construction: Crafted from premium aluminum materials, our mold guarantees exceptional durability and longevity, withstanding the rigors of high-volume production cycles.

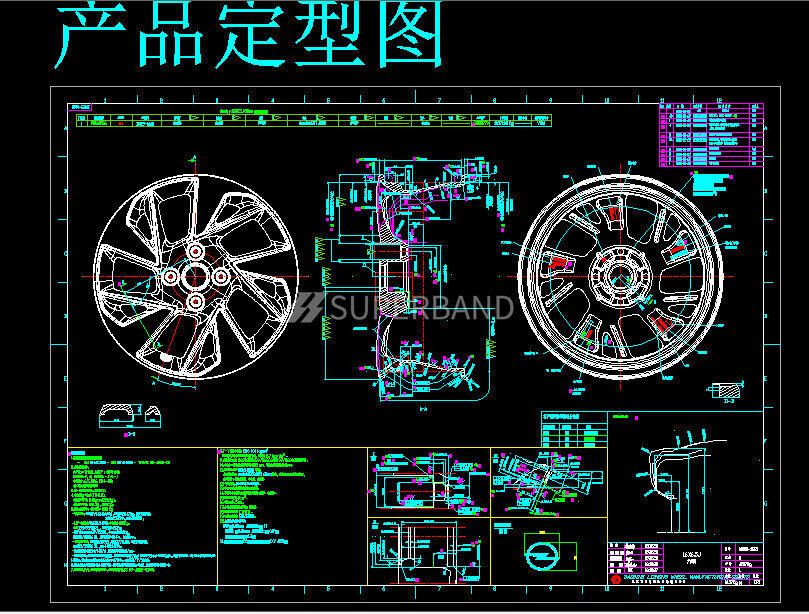

Precision Engineering: Each mold is meticulously engineered to precise specifications, guaranteeing consistent and flawless wheel production, and meeting the exacting standards of automotive manufacturers.

Optimized Design: The design of our mold facilitates seamless flow-forming processes, resulting in impeccably shaped wheels with enhanced structural integrity and aesthetic appeal.

Compatibility: Compatible with a wide range of automotive wheel sizes and designs, our mold offers versatility and adaptability to accommodate diverse production requirements.

Ease of Use: Designed for user convenience, our mold features intuitive controls and ergonomic design elements, streamlining the manufacturing process and maximizing productivity.

Reliable Performance: With a proven track record of reliability and performance, our mold empowers automotive manufacturers to consistently produce high-quality wheels that exceed customer expectations.

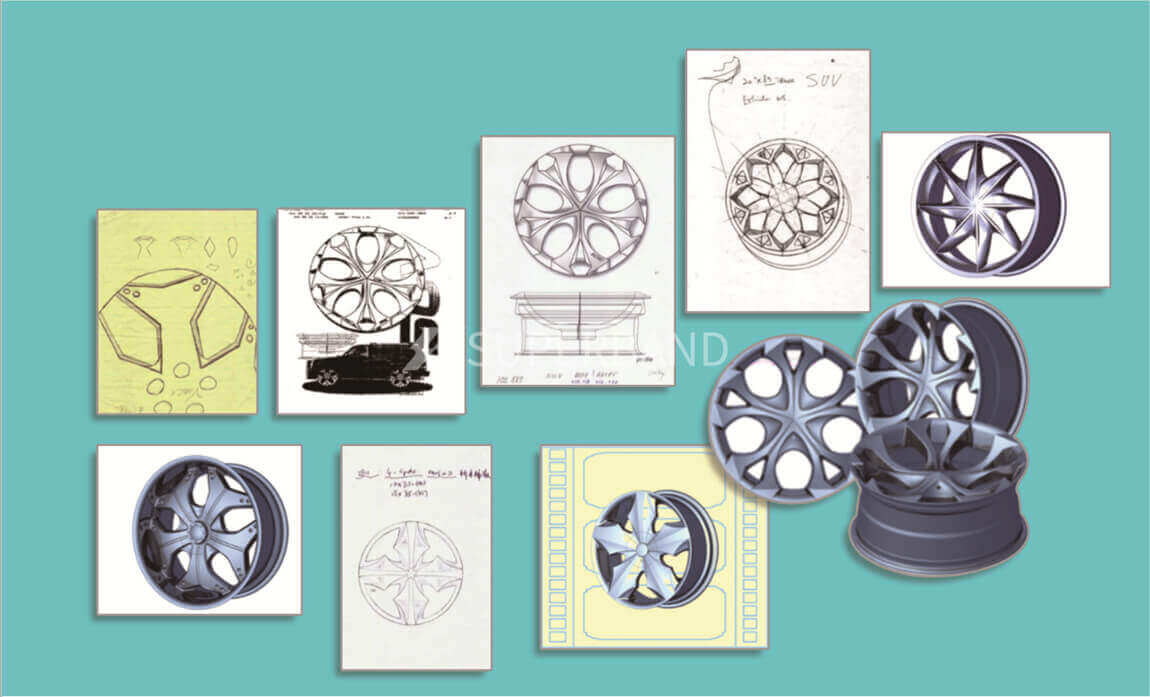

1. Receive Drawing From Client

2. DFM

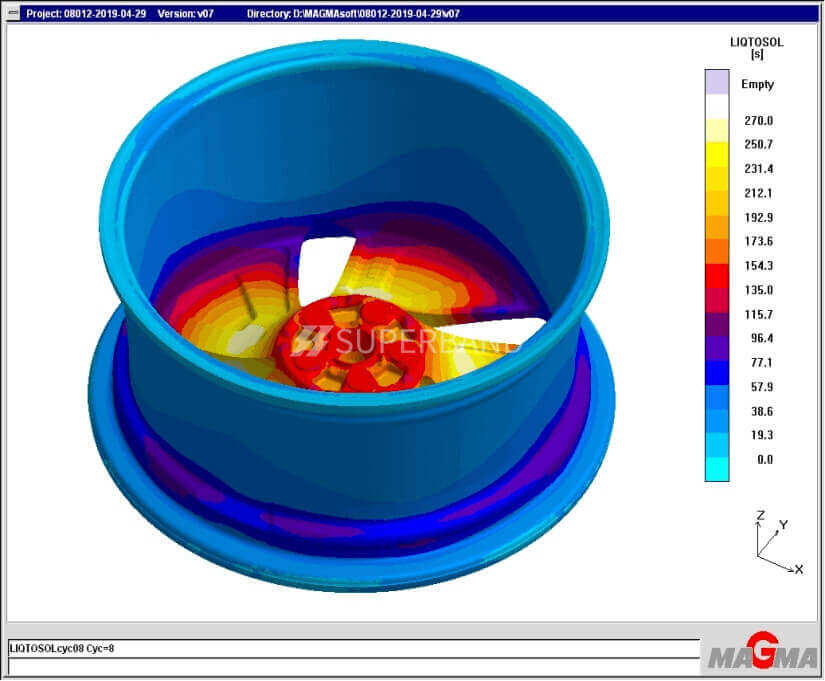

3. Mold Flow Analysis

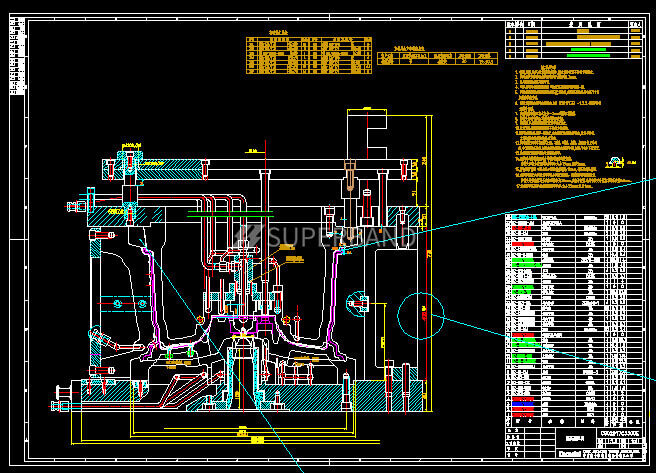

4. Mold 3D design

5. 2D

6. Prepare Mold Material

7. Rough Turning

8. Rough Milling

9. Vacuum Heat Treatment

10. Finish Turning

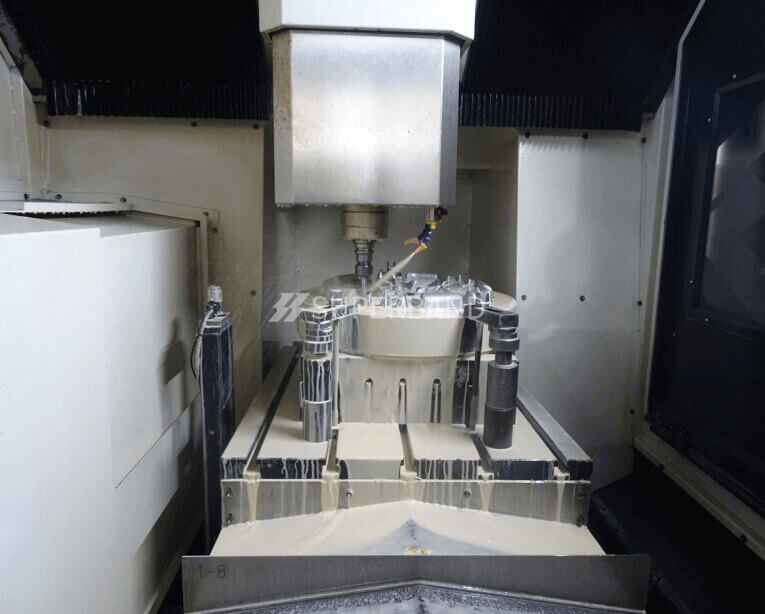

11. CNC-Milling

12. Finish Milling

13. Polishing

14. 3D Detection

15. Assembly

16. Packing & Delivery

1. Material Composition Inspection

2. Ultrasonic Flaw Inspection

3. Metallographic Inspection

4. Hardness Inspection

5. Handy 3D Scanner

6. 3D Scan Inspection

7. CMM Inspection

8. CMM Accuracy within 1 μm

There will have strict flow form molds simulation before shipment, which can guarantee the quality.

After receiving the molds, if there is any technical problem, our professional technical team can go to for your technical support on site.

Superband provide the management of mold’s whole life from mold design, Material research,mold manufacturing ,quality control, mold simulation, on -site technical support and after sales service.