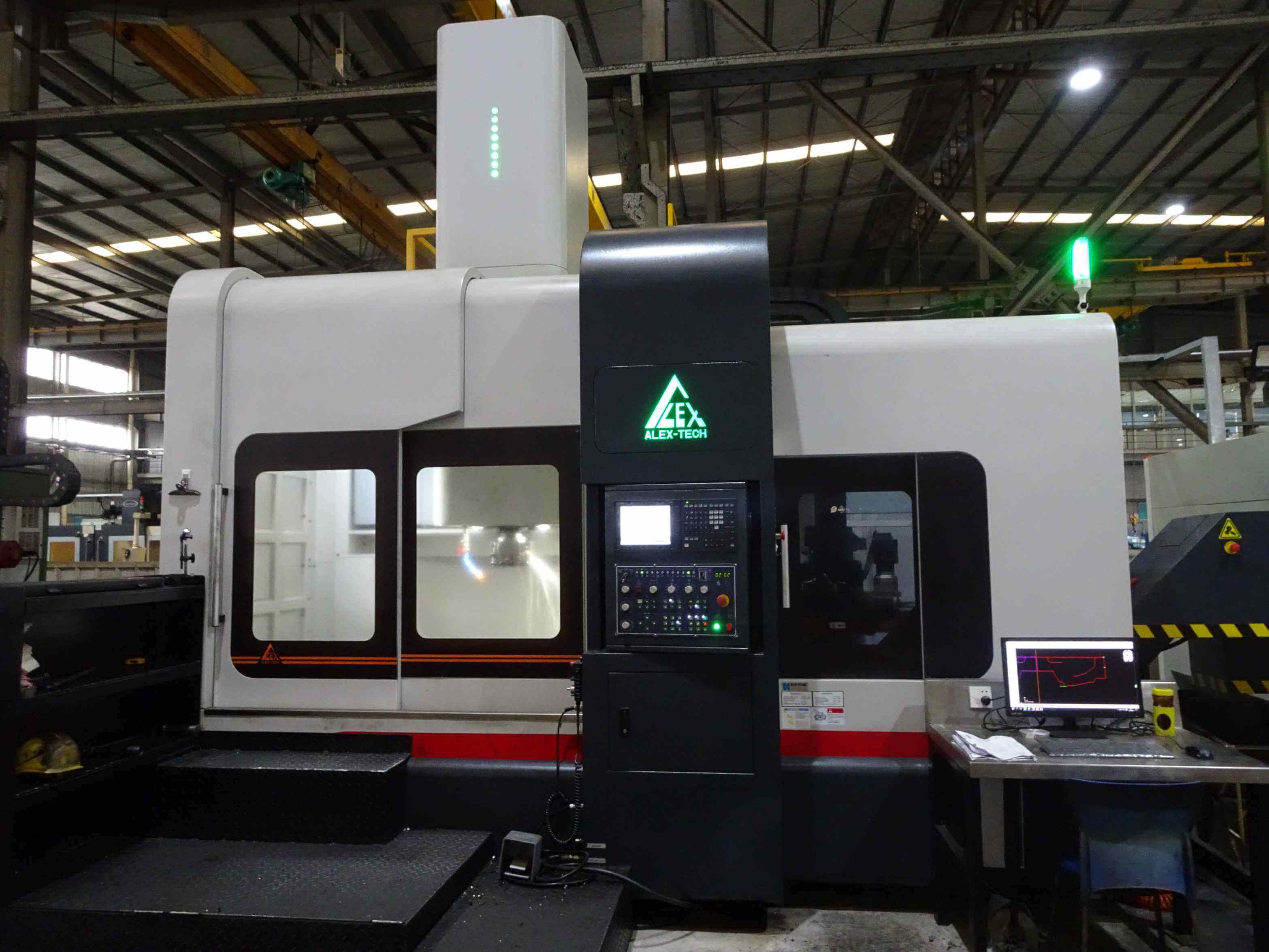

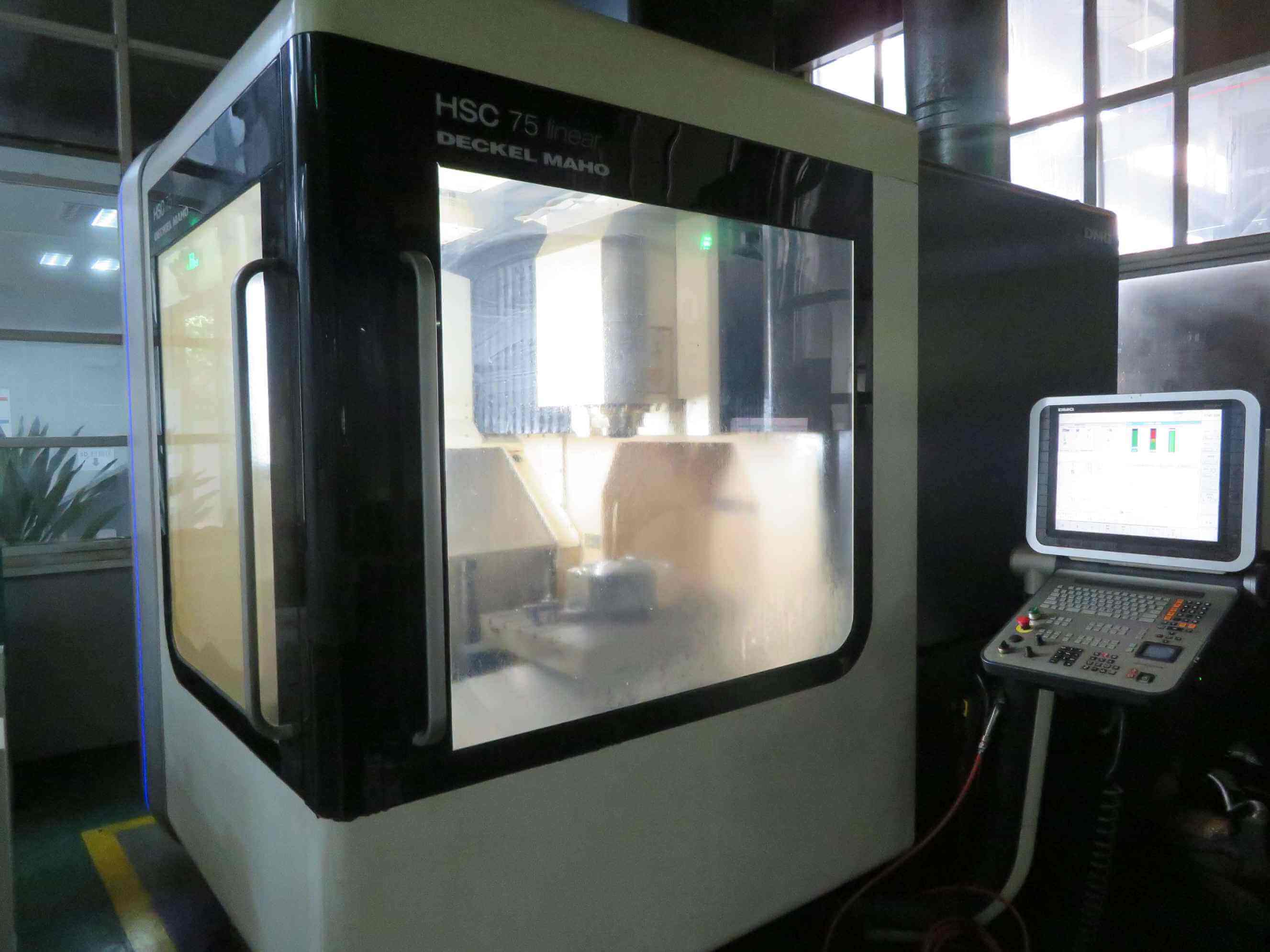

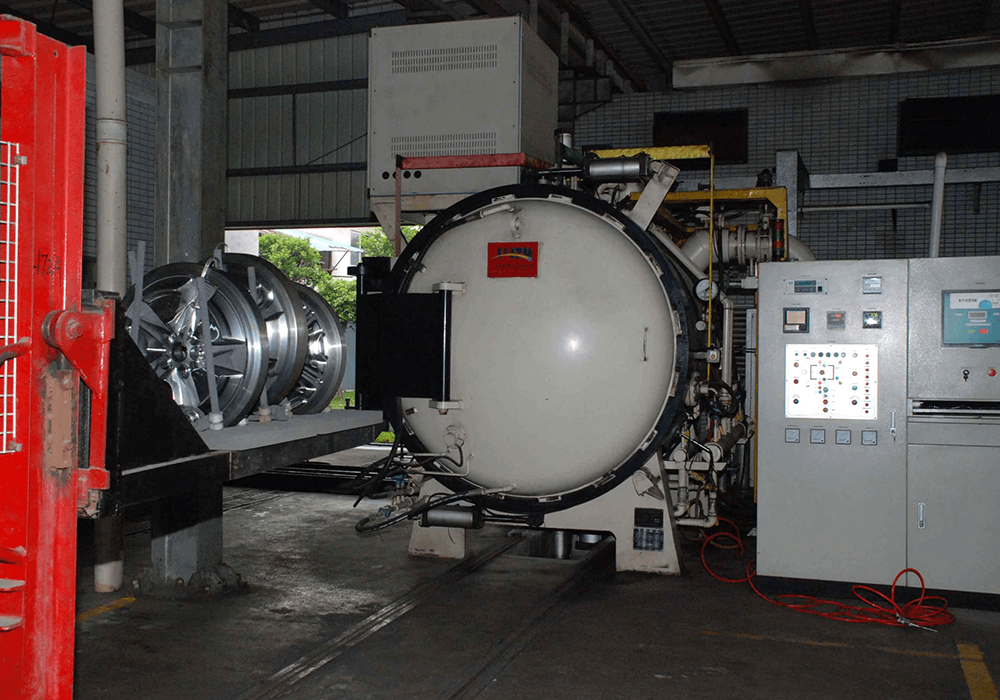

Superband owns over 100 sets DMG,MAKINO high-speed machining centers and other advanced CNC machines in total. Since there’re vacuum heat treatment plant ,optimizing the processing technology , grading machining ,MES application and APS system, the management level of intelligent mold manufacturing and production efficiency have been improved , and the mold quality ensured . The annual output of mold is over 3000 sets including wheel molds,chassis structure molds and other automotive parts die casting molds .Aluminum ally die casting parts annual output is over 5000 tons .

1990

Yanbu Superband Mould Factory was established

1992

entered into alloy wheels industry

1996

Renamed as Foshan Nanhai Superband mould Co.,Ltd

1997

set up Foshan Nanhai Superband-Arcontec Mould Co.,Ltd

2000

Set up Superband (H.K.) Industrial Limited

2000

2003

set up Qinghuangdao Superband Mould Co.,Ltd

2004

Set up Shanghai Superband Mould Co.t Ltd

2004

2006

Set up Kunshan Superband Mould Co.,Ltd

2006

Won numerous awards in first China wheels design competition

2016

transition to modern enterprise system

2018

Start ”Superband 2025” intelligent manufacturing and change to new company strategies “Lightweight, Intelligent,internationalization”

2019

Passed the intellectual property management system certification,won the title of national intellectual property enterprise,It marking the company reached into new level in the combination of intellectual property and business strategy.

2019

Launched Industry 4.0 intelligent manufacturing plan

2020

Get VDA 6.4 Certificate