In aluminum alloy casting molds , Superband provide mold lifetime management as well as Wheel & mold design, mold manufacturing,mold trials and process support etc service . Especially the innovation and research on high efficient water cooling mold structure development, casting temperature ,stress simulation ,high precision mold processing technology and mold temperature real time scanning , it not only satisfy with different customers’ personalize needs. But also let us step into international advanced level in comprehensive technical ability in casting mold.

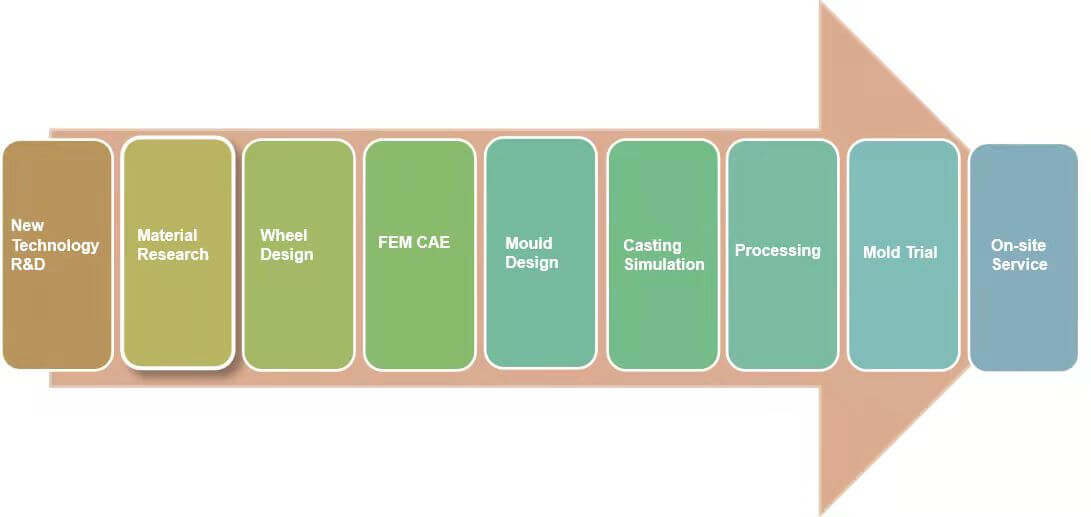

In aluminum alloy die casting parts, Superband possesses whole casting process technical service abilities ,including material research,product and mold design, casting simulation ,mold manufacturing ,process research etc.,especially in high performance aluminum alloy material,high vacuum die casting process of innovation and research,continue to provide customers with high value-added solutions .

There are 64 professional engineers in the technology center which made of product design department, wheel mold department, die casting mold department ,R&D process department and automobile lightweight part mold department , also set up the metallographic laboratory and mechanics laboratory .We have always attached great importance to R&D ,investing 30% of sale volume into our engineering .

Superband is the only one which equipped with LPDC and HPDC trial and process R&D ability mould supplier in the world .Ensure the reason-ability of mould design ad process , realize the fast mould trial and mass production

Superband pays attention to the combination of production ,education and research technology innovative mode.We take part in extensive and in-depth technical cooperation and exchanges with many well-known domestic universities,enterprises and scientific research institutions ,such as South China University of technology , Chinalco institute of Science and technology and ZTE corporation. With industry-university-research cooperation as the link, we promote the application and transformation of scientific and technological achievements together .