It is the combination with low-pressure die casting and pressure.

Upgrade your automotive manufacturing process with the cutting-edge Aluminum Automotive Control Arm Mold from Superband. Crafted with precision and durability in mind, this mold is engineered to change your production line, ensuring top-notch quality and performance in every control arm produced.

| Equipment Name | QTY |

| DMG/MAKINO High-speed Machining Center | 3 |

| Machining Centr /High Speed CNC Machining Center | 52 |

| Five-axis Machining Center | 1 |

| EDM | 10 |

| Lathe | 28 |

| Hydraulic Tipping Crucible Furnace | 1 |

| Holding Furnance | 1 |

| Heat Treatment Furnace | 2 |

| Vacuum High Pressure Gas Quenching Furnance | 1 |

| Tempering Furnace | 4 |

| Gas Nitriding Furnace | 1 |

| Gas Carburizing Furnace | 2 |

| CMM | 3 |

| Die Spotting Machine | 2 |

| Sand-Blasting Machine | 1 |

| Milling Machine | 20 |

| Welding Machine | 18 |

| Laser cutting Machine/Wire Cutting Machine /Machine Tool | 11 |

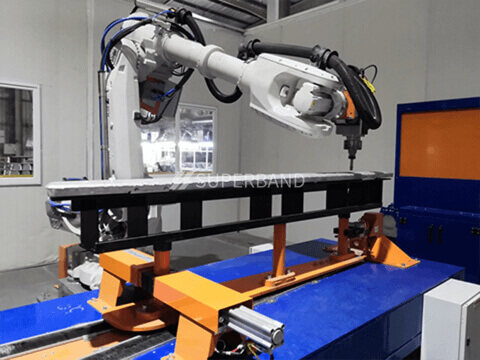

| Welding Robot System | 2 |

| Metallographic Detector | 1 |

| Hardness Tester | 1 |

1.Sub frame mould

2.Control arm mould

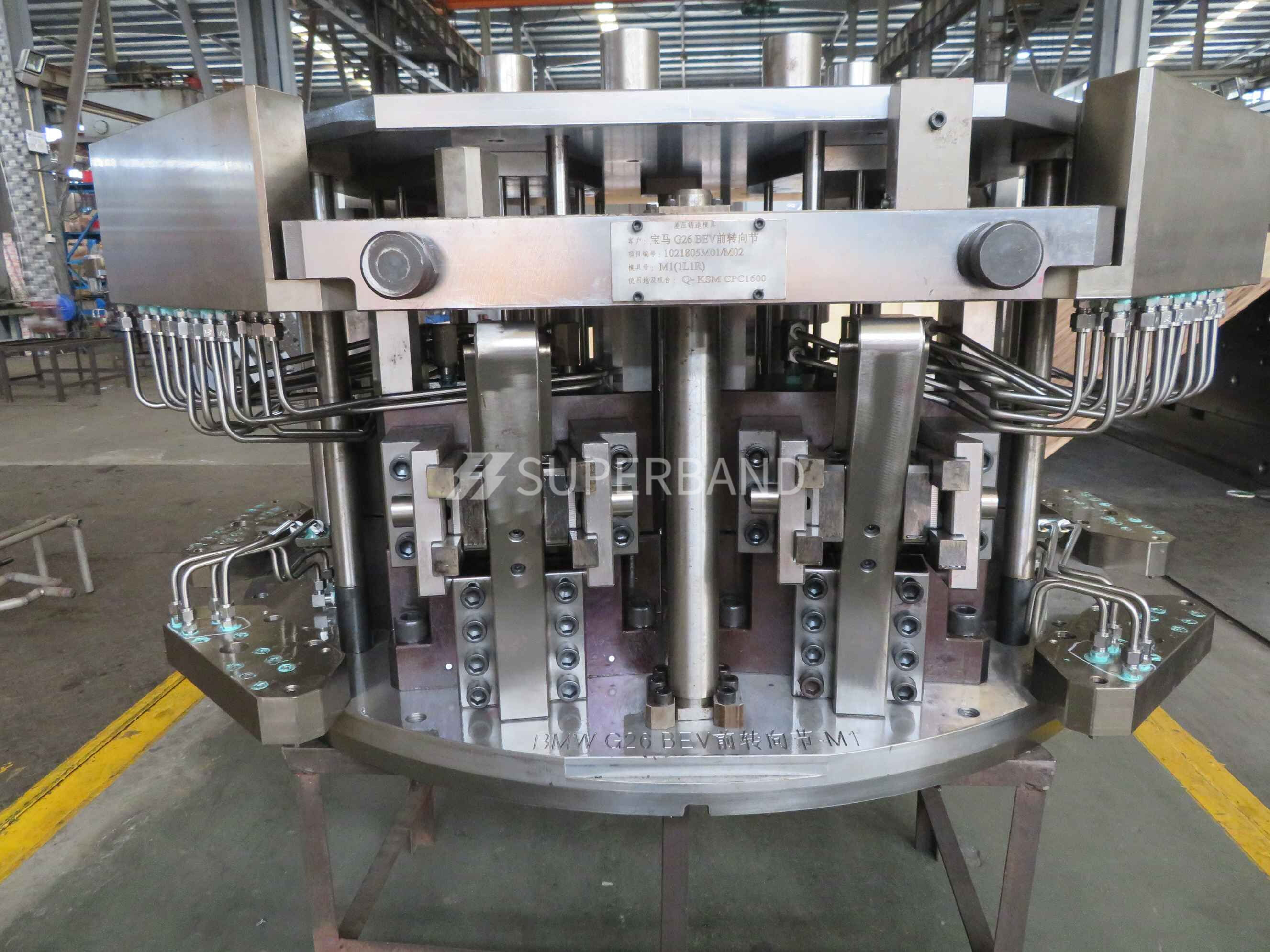

3.Steering knuckle mold/wheel car bracket casting mould

4.Shock tower vacuum cast mold

1.Send us drawing 2D/3D or provide us sample for ref ;

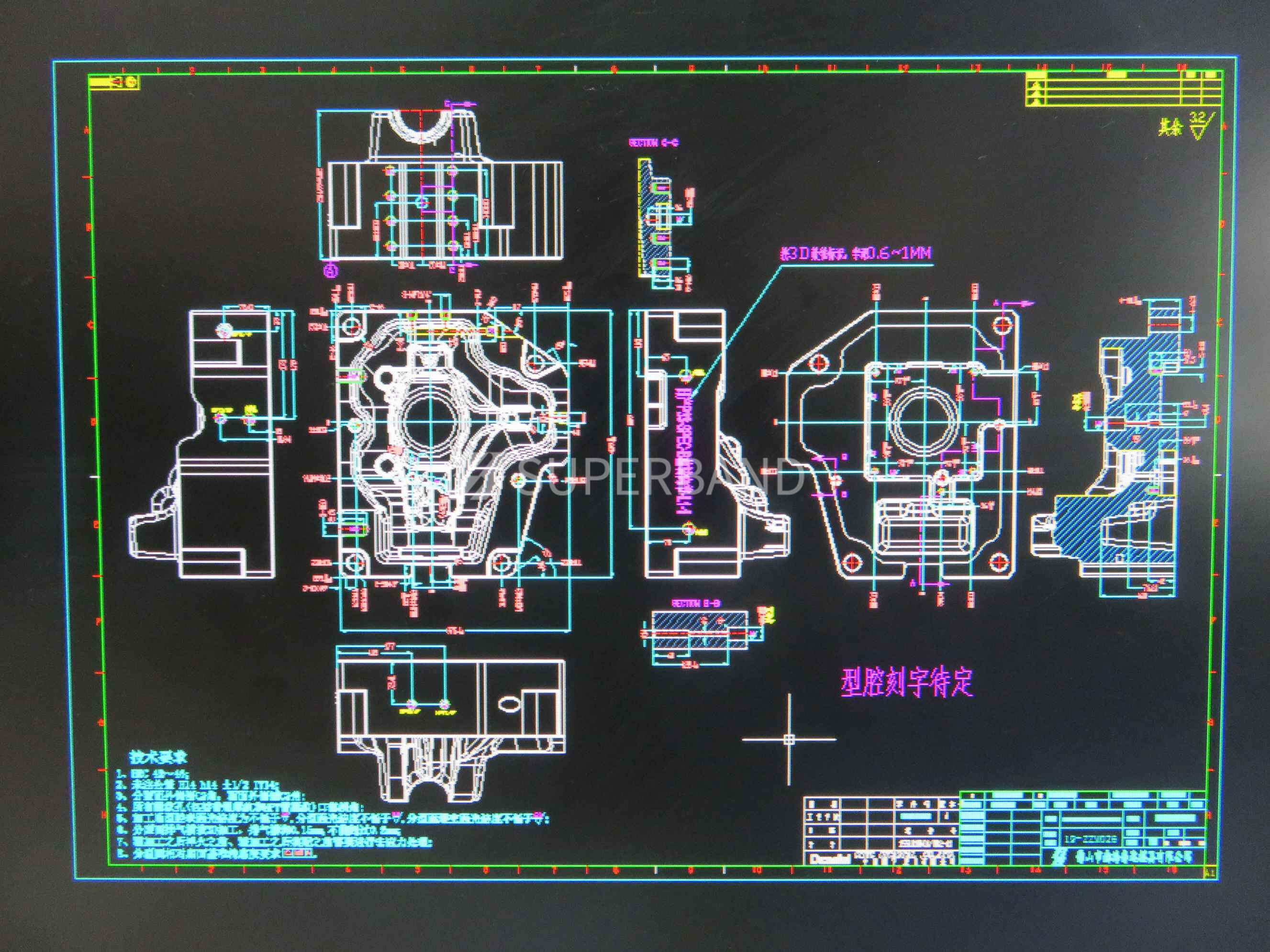

2.Mould design

3.Technology research

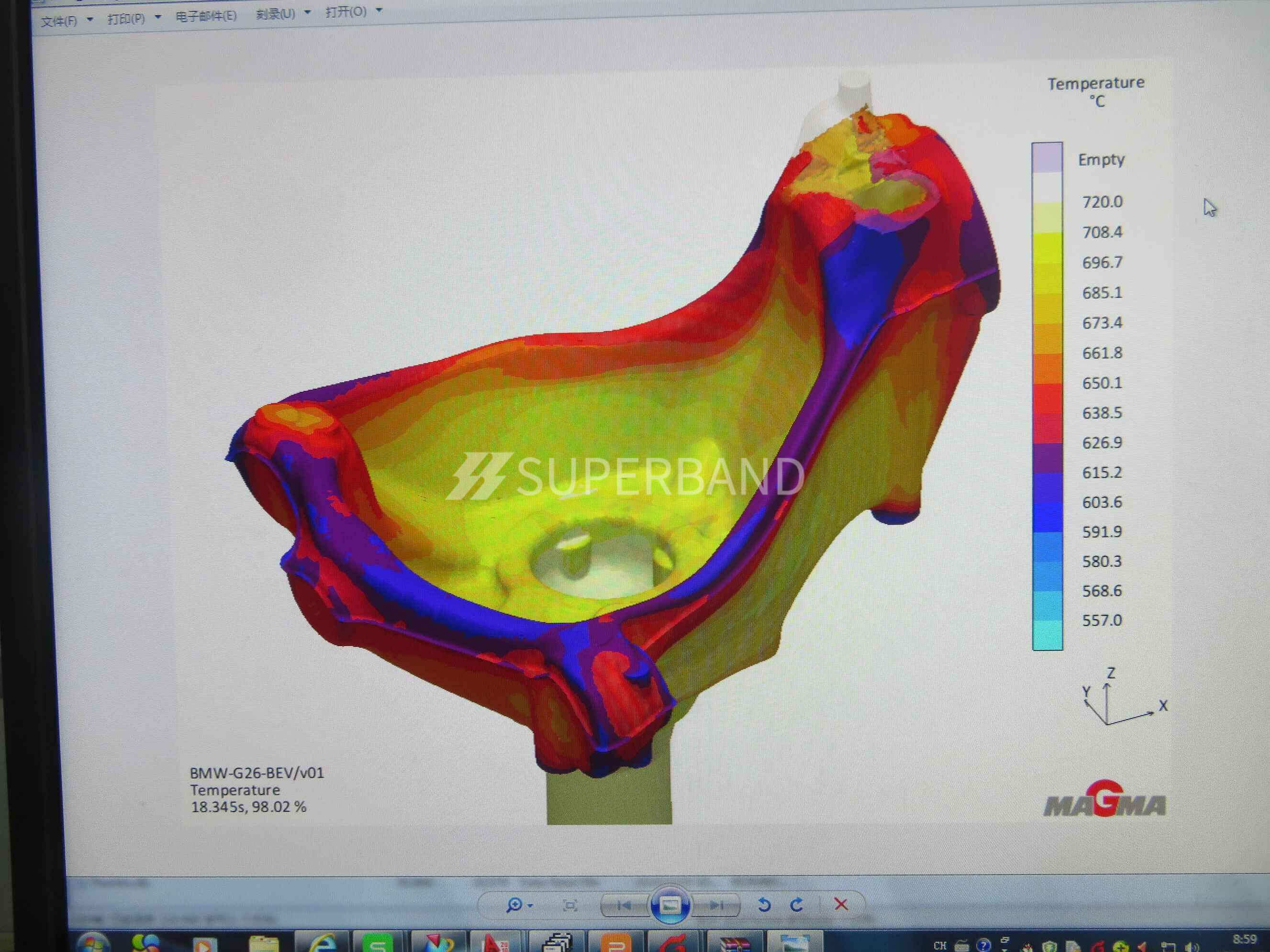

4.Mould simulation

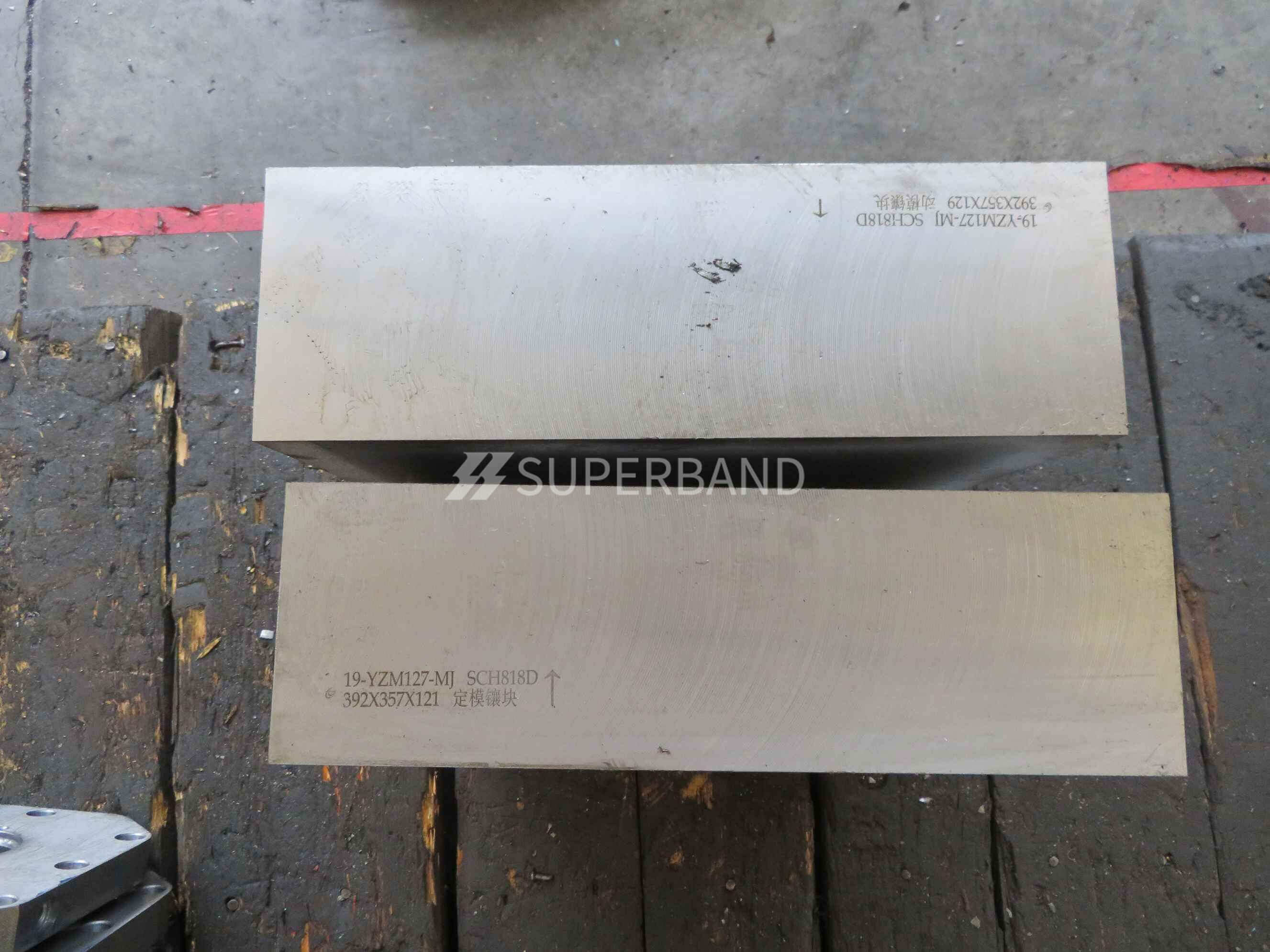

5.Material analysis

6.Mould manufacturing

7.Inspection

8.Shipment

1. Customer Provide Drawing Or Sample

2. DFM

3. Mold Flow Analysis

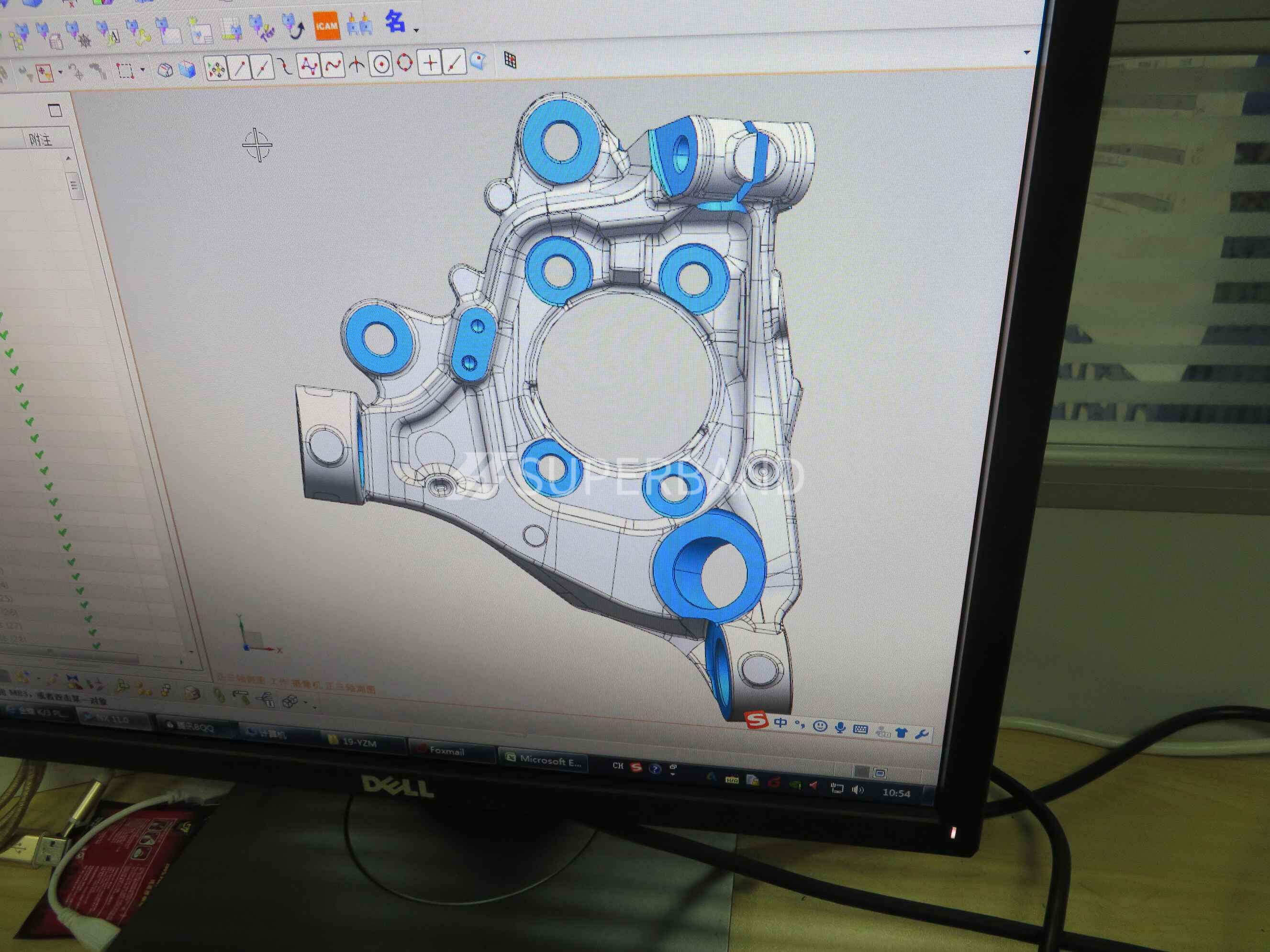

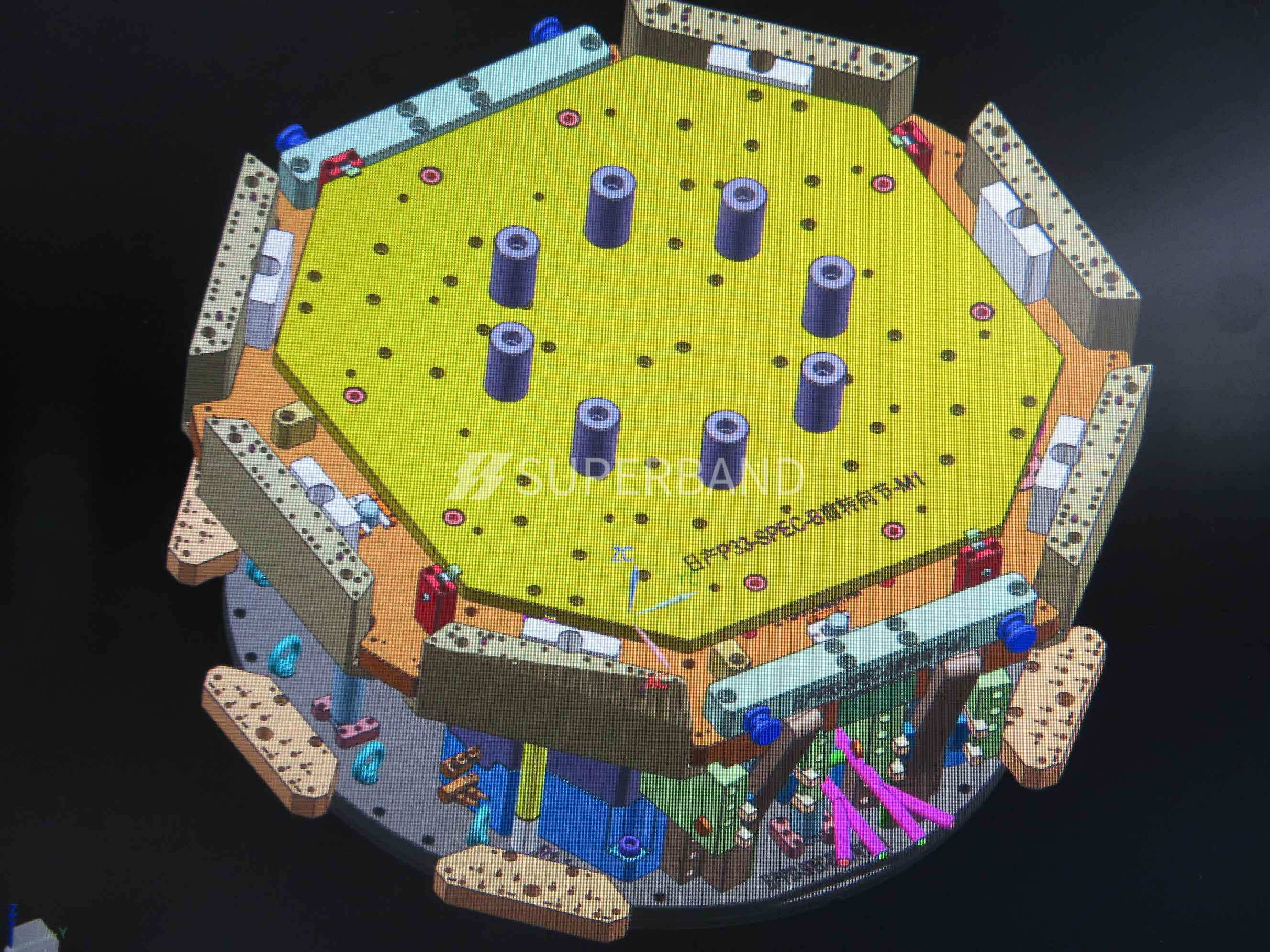

4. Mold 3D Design

5. 2D Design

6. Prepared Mold Material

7. Wire-Cutting

8. CNC

9. EDM

10. Mold Polishing

11. Assembly

12. Encasement & Delivery

There will have strict mold simulation before shipment , which can guarantee the quality.

After receiving the molds, if there is any technical problem, our professional technical team can go to for your technical support on site.

Superband provide the management of mold’s whole life from mold design, Material research, mold manufacturing ,quality control, mold simulation, on-site technical support and after sales service.