As aluminum has excellent material flowability, high corrosion resistance, and high dimensional stability with complex parts shape, aluminum die casting is the most common process to produce aluminum die casting mould parts used in diverse industries.

Aluminum has good corrosion resistance, high thermal conductivity, and electrical conductivity, making it a good alloy commonly used in aluminum die casting factory.

Superband is one of the aluminum die casting mold suppliers, whether it is vacuum aluminum die casting, die casting aluminum molds, or aluminum car subframe molds, we have professional experience in making them.

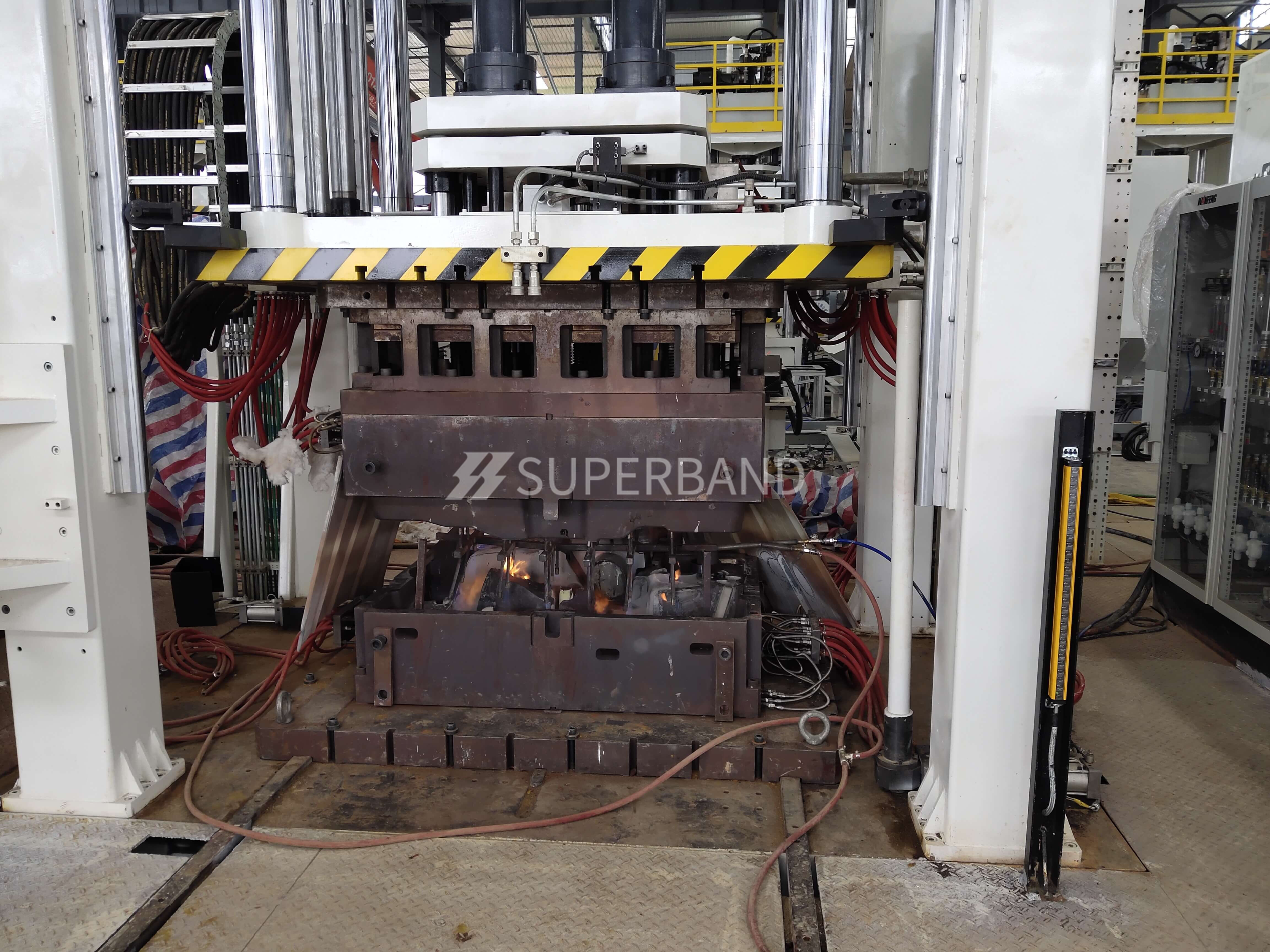

Low-pressure die casting is a method of production that uses pressure -rather than gravity to fill molds with molten metal. In this process, the holding furnace located below the cast and the liquid metal forced upwards through to rise tube and into the cavity.

The pressure is applied constantly, sometimes in increasing increments, to fill the mold and hold the metal in place within the die until it solidifies. Once the cast has solidified, the pressure is released, and any residual liquid in the tube or cavity flows back into the holding furnace for recycling. When cooled, the cast is simply removed.

| Equipment Name | QTY |

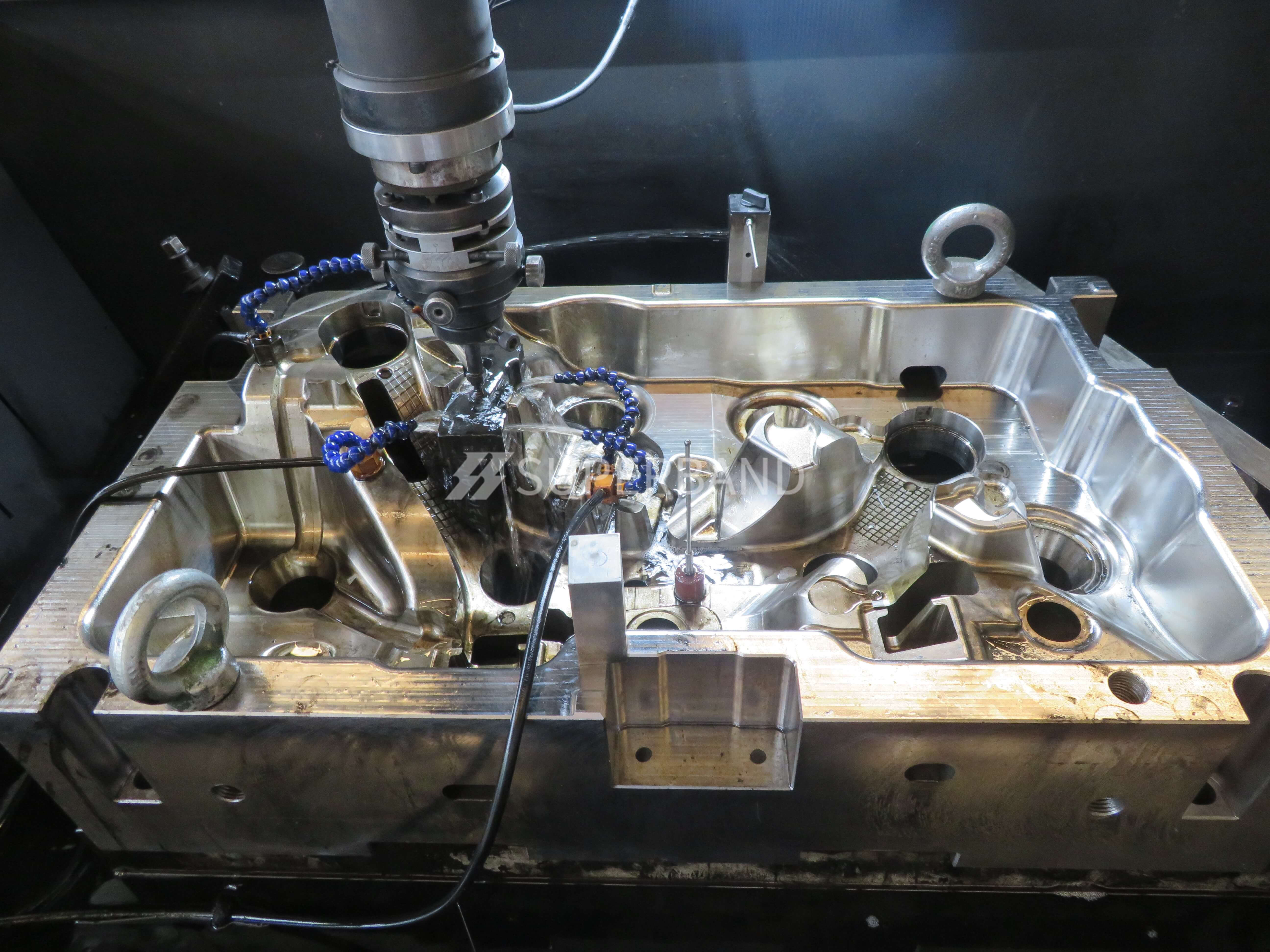

| DMG/MAKINO High-speed Machining Center | 3 |

| Machining Centr /High Speed CNC Machining Center | 52 |

| Five-axis Machining Center | 1 |

| EDM | 10 |

| Lathe | 28 |

| Hydraulic Tipping Crucible Furnace | 1 |

| Holding Furnance | 1 |

| Heat Treatment Furnace | 2 |

| Vacuum High Pressure Gas Quenching Furnance | 1 |

| Tempering Furnace | 4 |

| Gas Nitriding Furnace | 1 |

| Gas Carburizing Furnace | 2 |

| CMM | 3 |

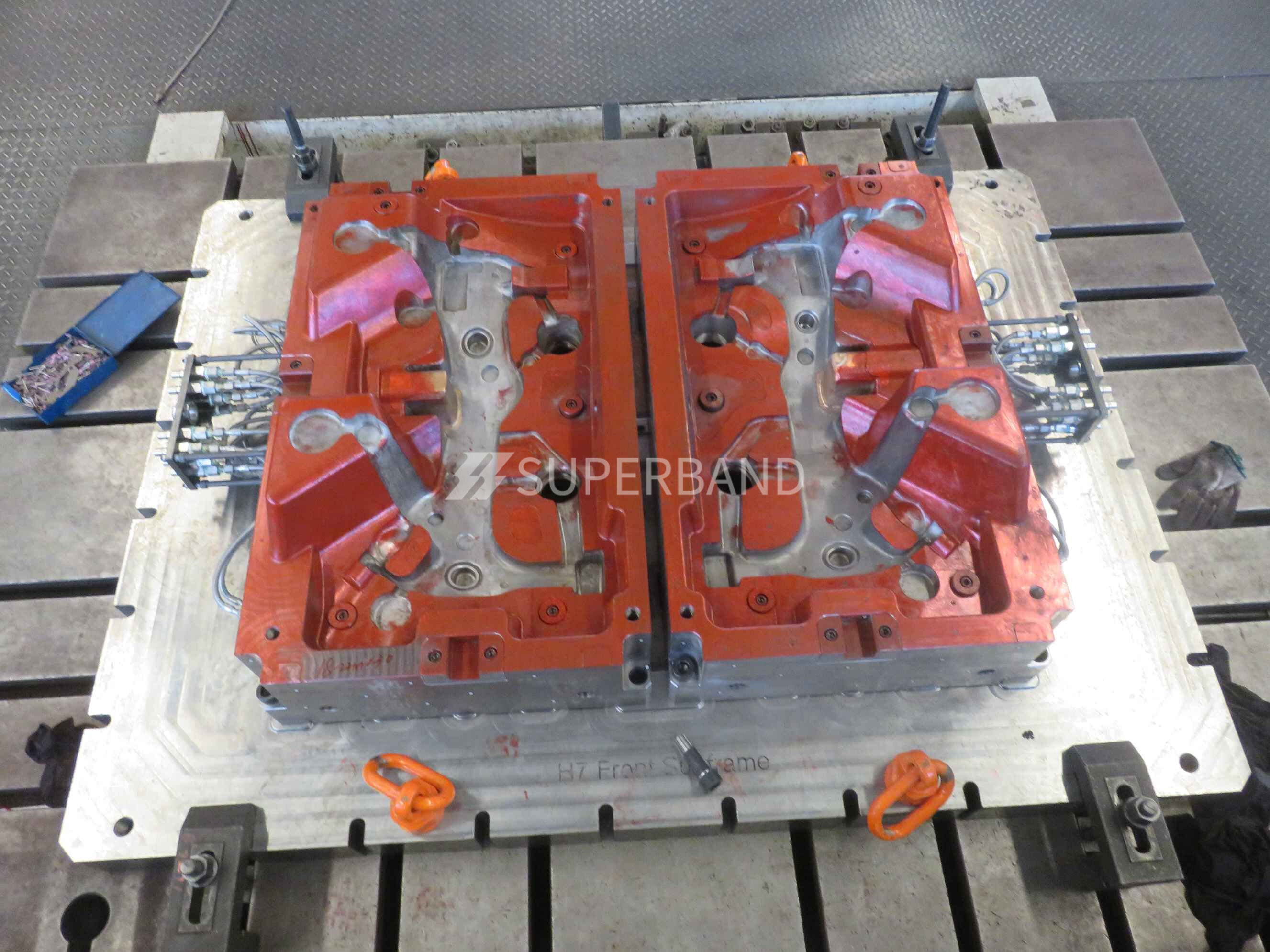

| Die Spotting Machine | 2 |

| Sand-Blasting Machine | 1 |

| Milling Machine | 20 |

| Welding Machine | 18 |

| Laser cutting Machine/Wire Cutting Machine /Machine Tool | 11 |

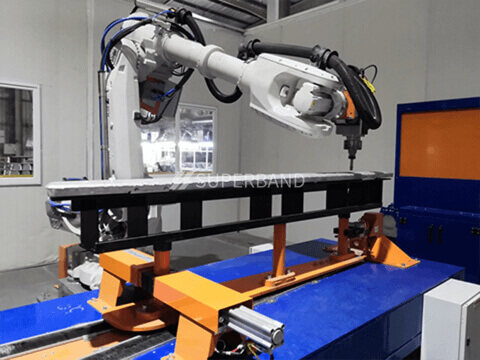

| Welding Robot System | 2 |

| Metallographic Detector | 1 |

| Hardness Tester | 1 |

1. Customer Provide Drawing Or Sample

2. DFM

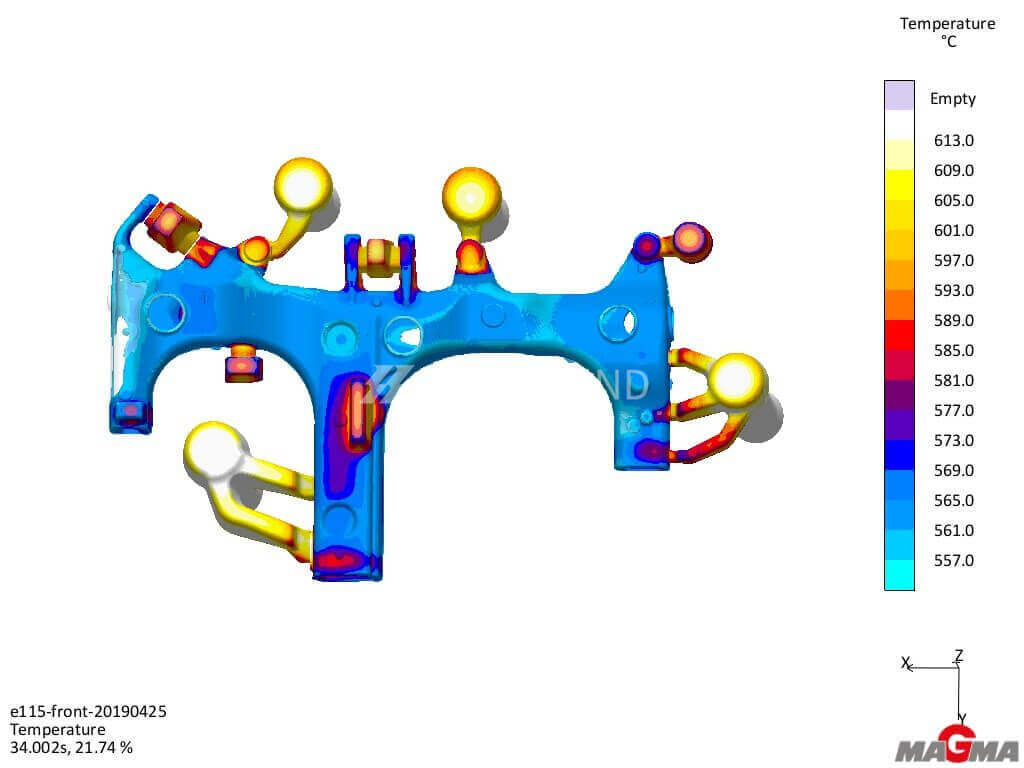

3. Mold Flow Analysis

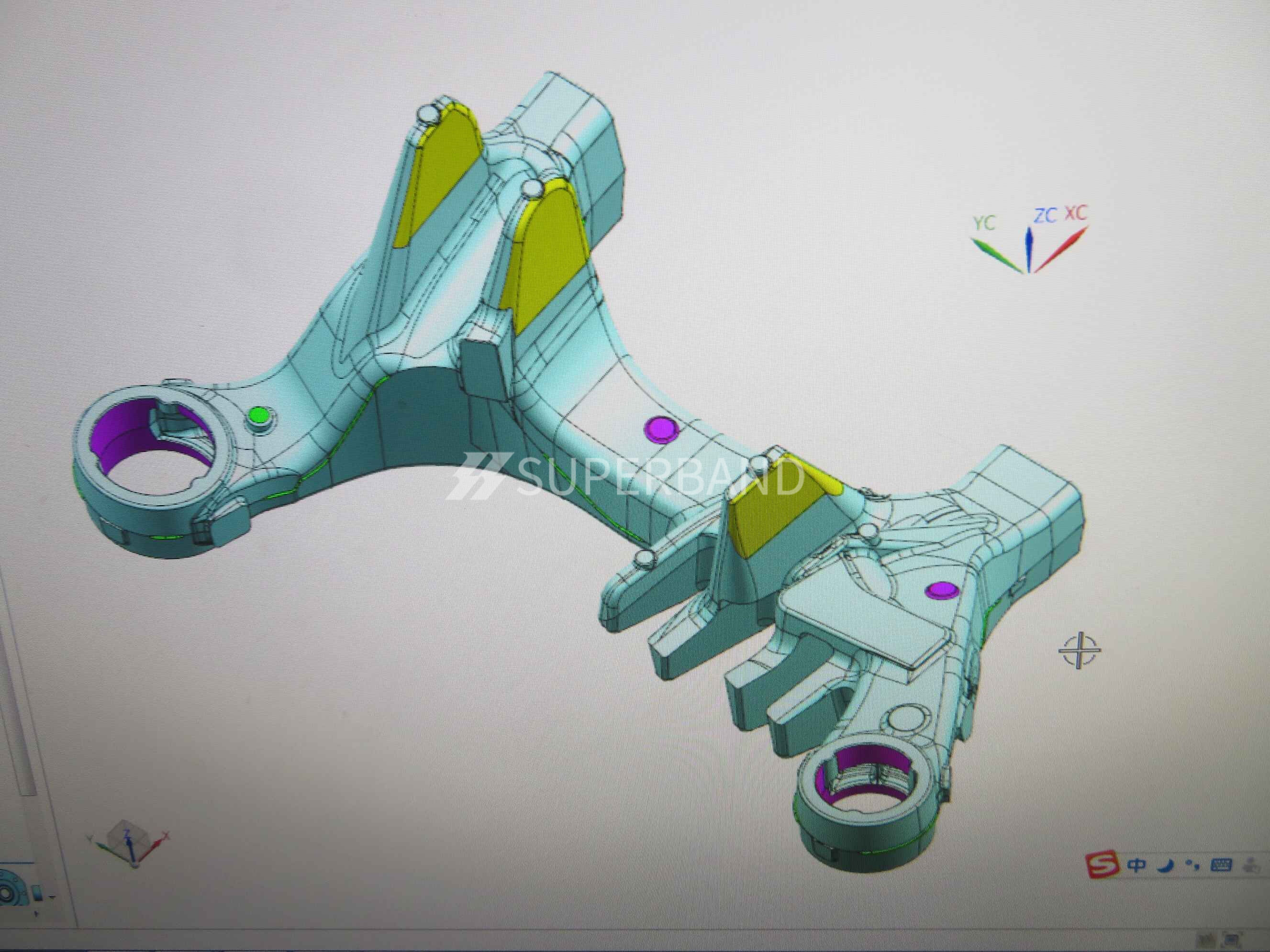

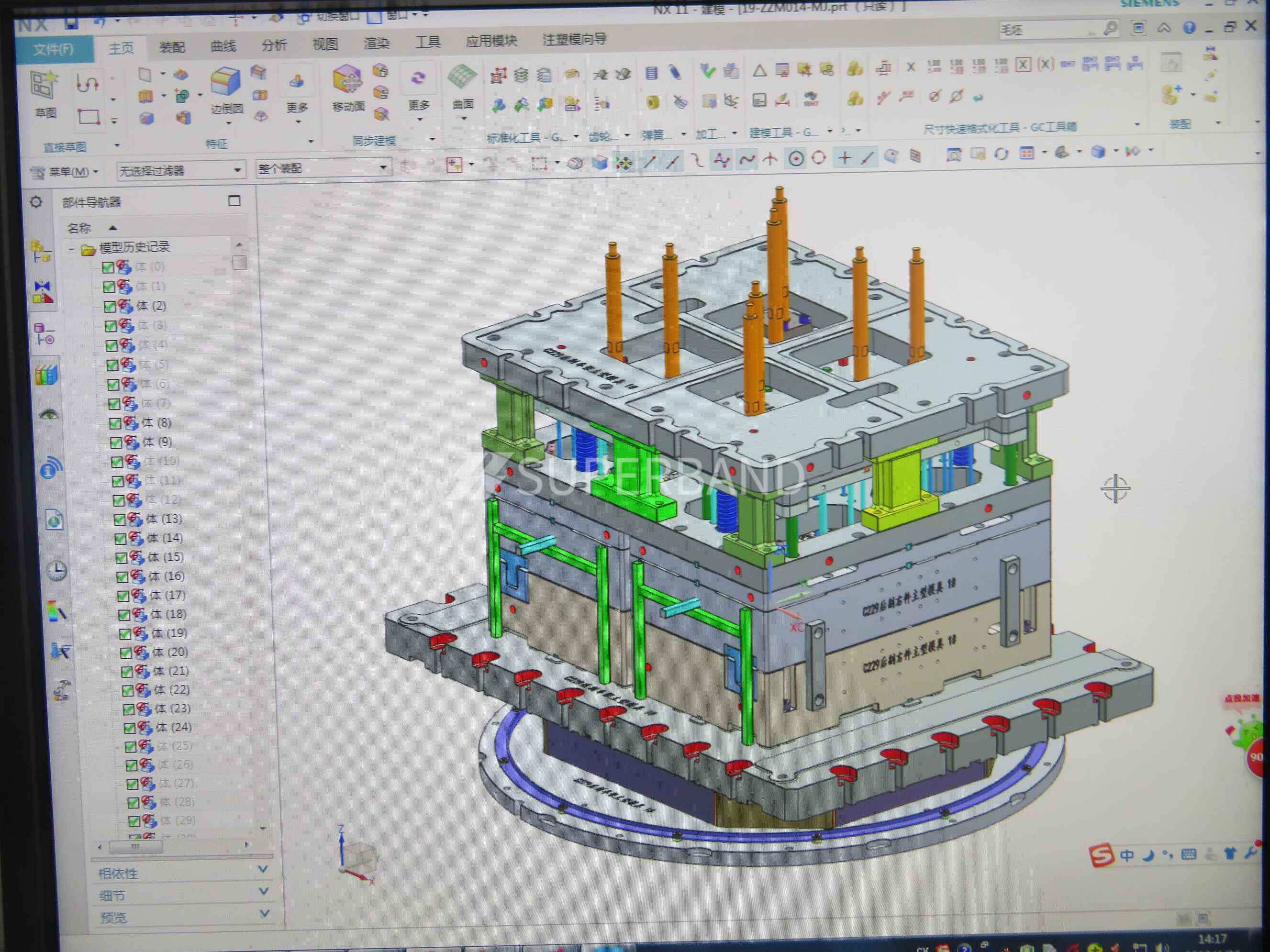

4. Mold 3D Design

5. 2D Design

6. Prepare Mold Material

7. Wire-cutting

8. CNC

9. EDM

10. Mold Polishing

11. Assembly

12. Mlod Trial & Sampling

Superband aluminum automotive subframe molds offer cost-effective solutions for automotive manufacturers seeking to optimize their production processes. With reduced machining times, minimal maintenance requirements, and extended mold lifecycles, our molds help to streamline manufacturing operations and lower overall production costs.

Committed to environmental sustainability, Superband's aluminum automotive subframe molds are crafted from recyclable materials, minimizing waste and reducing our carbon footprint. By choosing our molds, automotive manufacturers can align with eco-friendly practices while achieving superior quality and performance in their production processes.

Superband's aluminum automotive subframe molds combine precision engineering, lightweight construction, optimized design features, corrosion resistance, efficient heat dissipation, customization options, cost-effective solutions, and environmental sustainability to deliver superior performance and reliability in automotive manufacturing applications.

* Material composition inspection

* Ultrasonic flaw inspection

* Metallographic inspection

* Hardness Inspection

* Handy 3D scanner

* 3D scan inspection

* CMM inspection

* CMM accuracy within 1u m

There will have strict aluminum die casting subframe mold simulation before shipment, which can guarantee the quality.

After receiving the molds, if there is any technical problem, our professional technical team can go to for your technical support on site.

Superband provide the management of mold’s whole life from mold design, Material research ,mold manufacturing ,quality control, mold simulation, on-site technical support and after sales service.