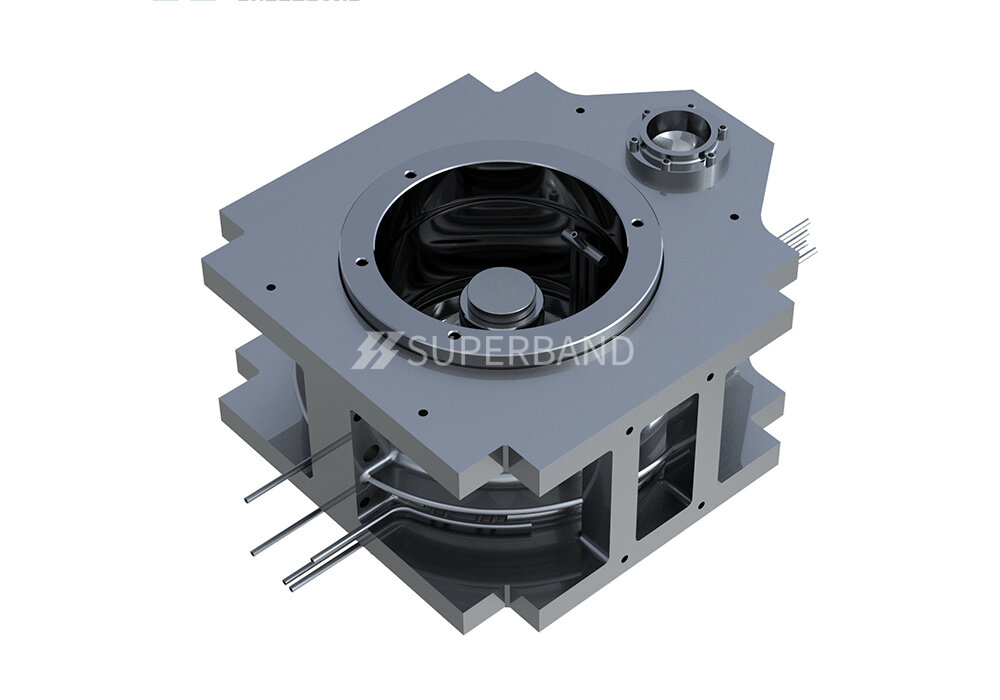

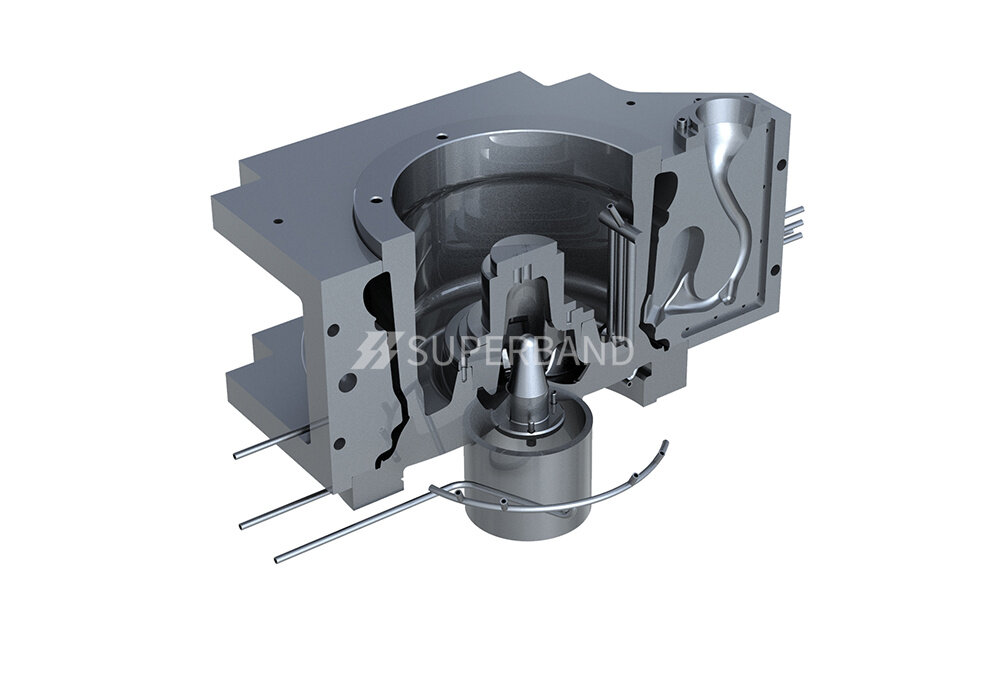

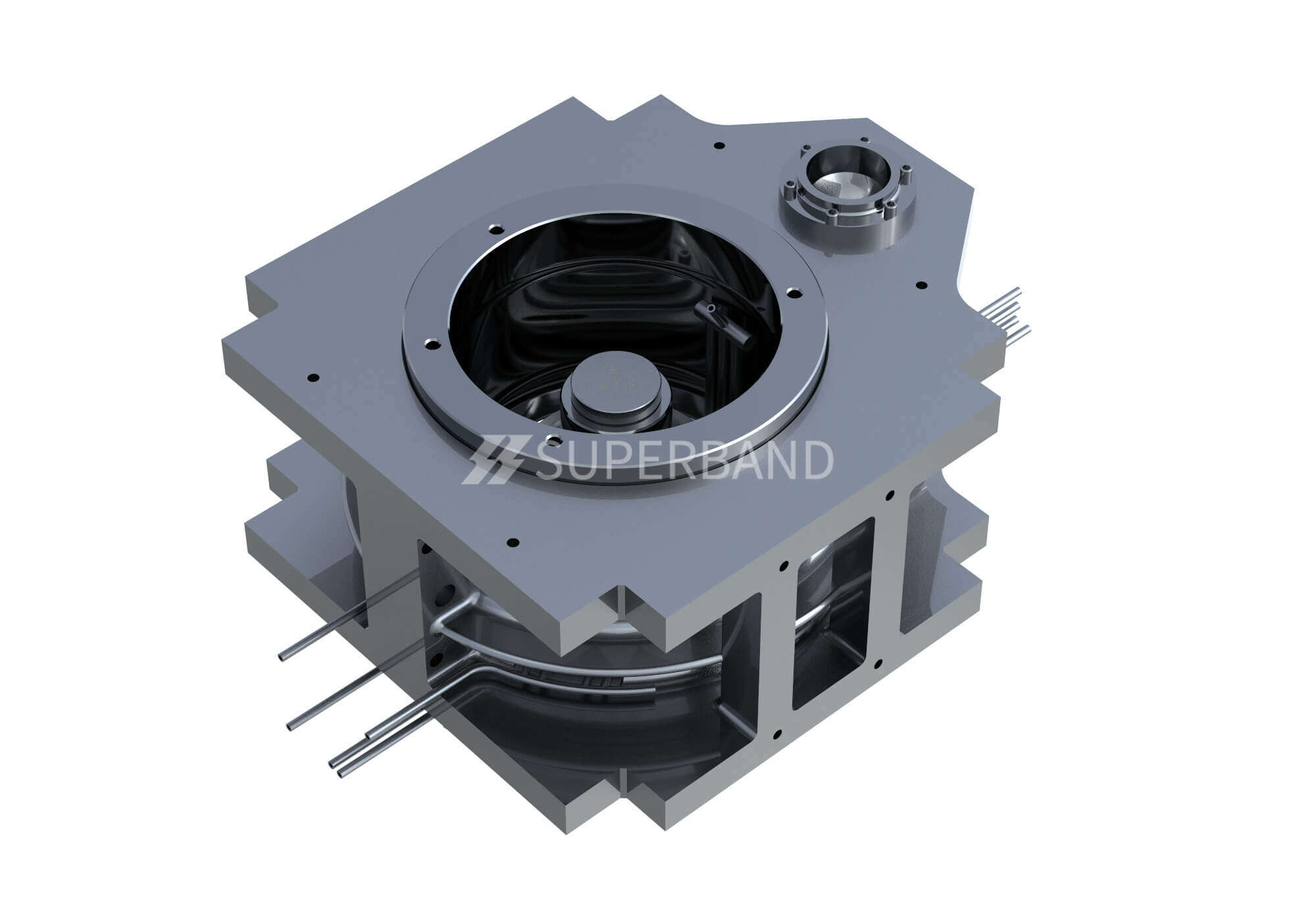

Gravity casting is the most traditional craft process, which involves injecting molten metal into a mold and allowing it to cool naturally. The price of the wheels made by gravity wheel mold making is cheaper. This kind of Gravity Aluminum Auto Wheel has less and uneven density, which is the disadvantage.

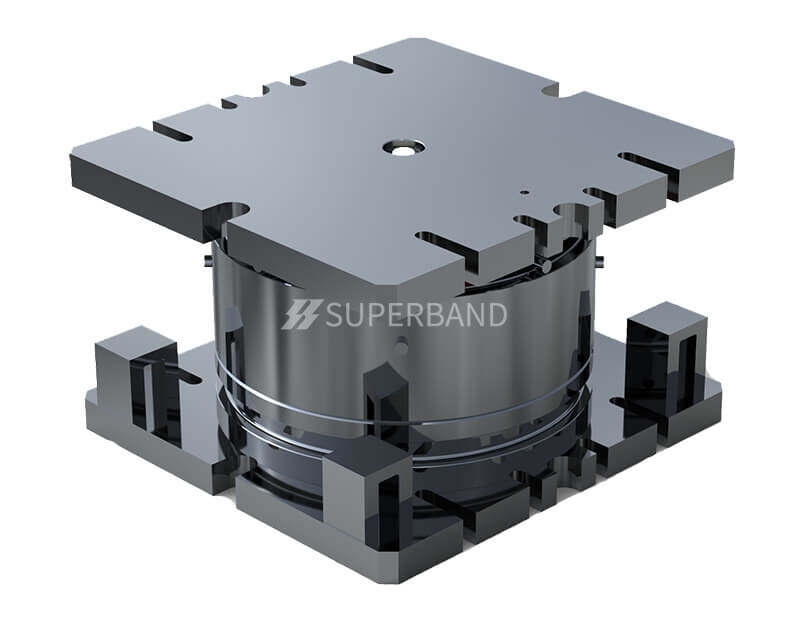

Elevate your automotive wheel manufacturing process with Superband's Gravity Aluminum Auto Wheel Mold. Crafted with precision engineering and cutting-edge technology, our mold sets the industry standard for durability, performance, and efficiency. Designed to meet the stringent demands of automotive manufacturers, our mold ensures consistent and high-quality wheel production.

Ideal for automotive manufacturers, wheel production facilities, and machining shops, our Gravity Aluminum Auto Wheel Mold is the cornerstone of efficient and high-quality wheel manufacturing processes.

At Superband, we believe in pushing the boundaries of innovation and quality. Our Gravity Aluminum Auto Wheel Mold reflects our unwavering commitment to excellence, empowering manufacturers to achieve unparalleled results in automotive wheel production.

Gravity Wheel Mold Lifespan(OEM):2~30000 SHOTS

Gravity Wheel Mold Lifespan(AM):6~9000 SHOTS

Gravity Wheel Mold Making Material: Top/Bottom Core: H13/SKD61 Side Core:4140/FCD500

Using Hardness: Top Core:HRC28-32 Bottom Core:HRC40-45

Average Wall Thickness: To be confirmed

Specification: 12-32inch

No.of Cavity: One cavity

liquid Material: A356.2,AlSi7Mg,etc.

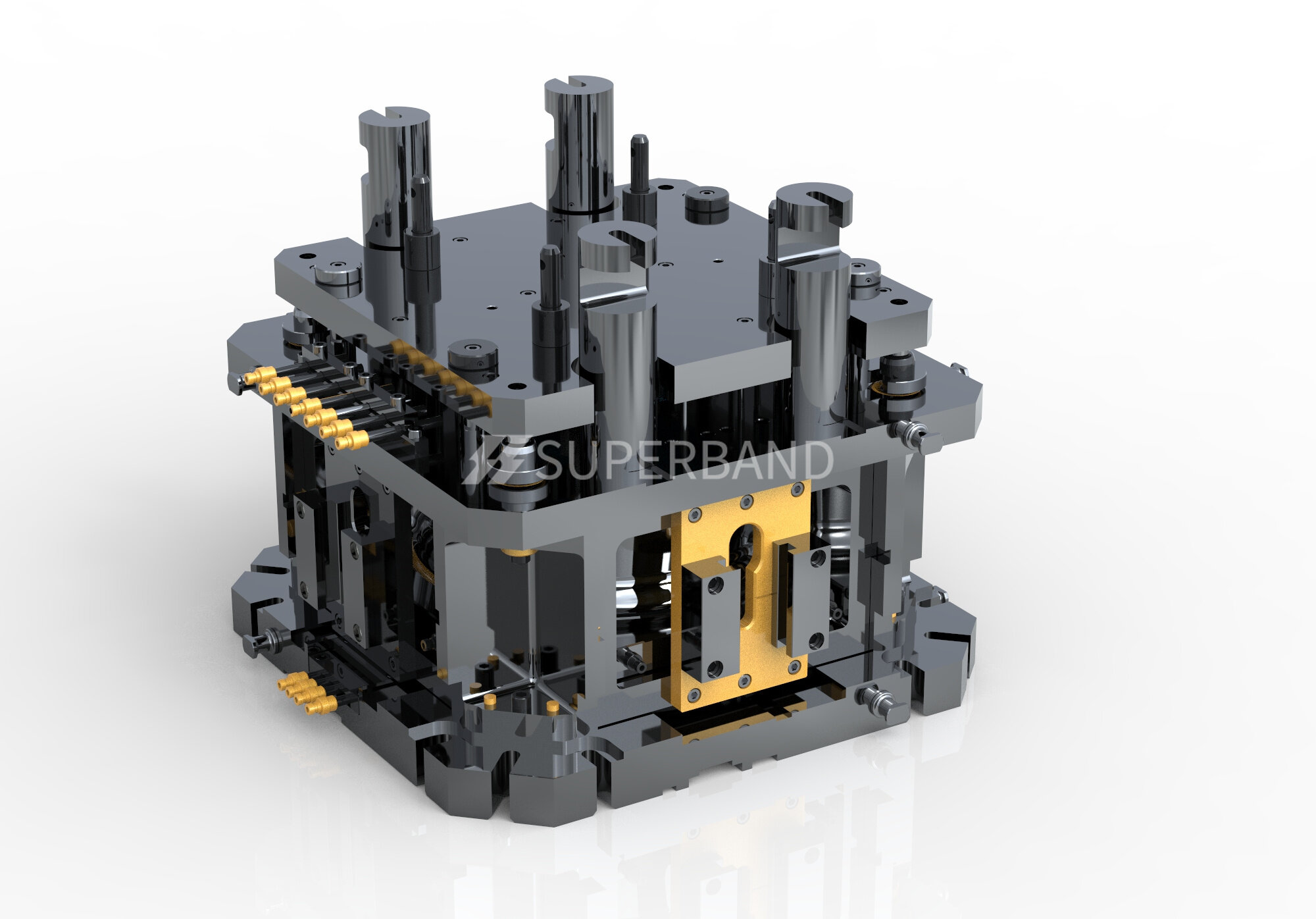

1. Low Pressure Water Cooling Air Cooling Mold

2. Gravity Mold

3. Flow Forming Mold

4. Forging Mold

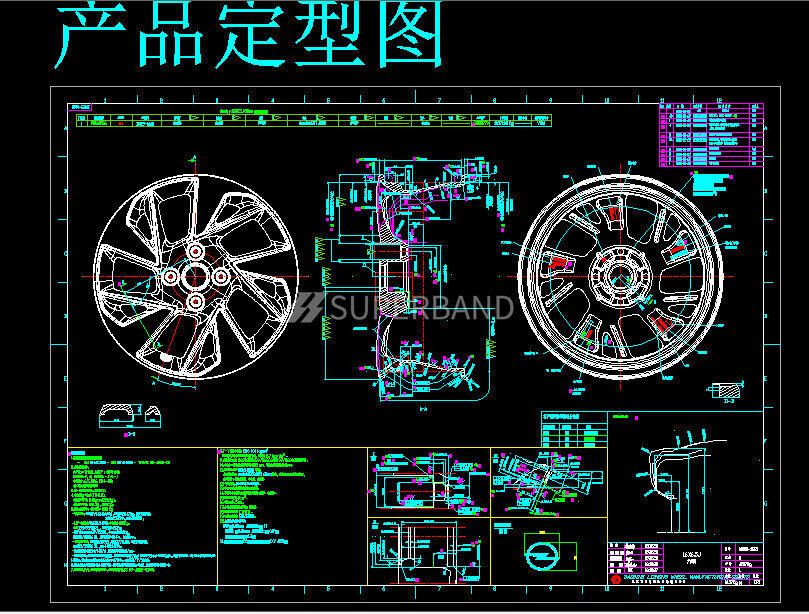

1. Receive Drawing From Client

2. DFM

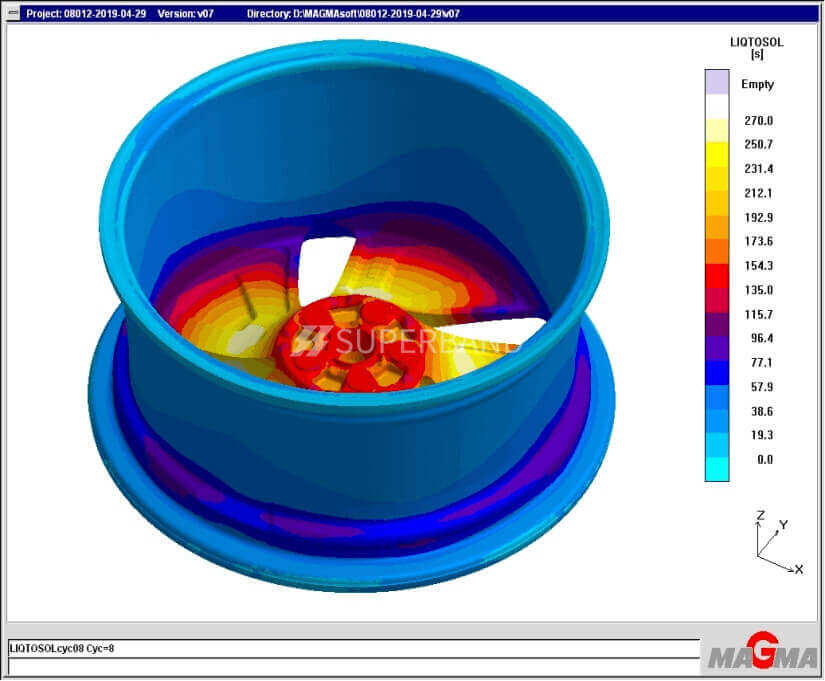

3. Mold Flow Analysis

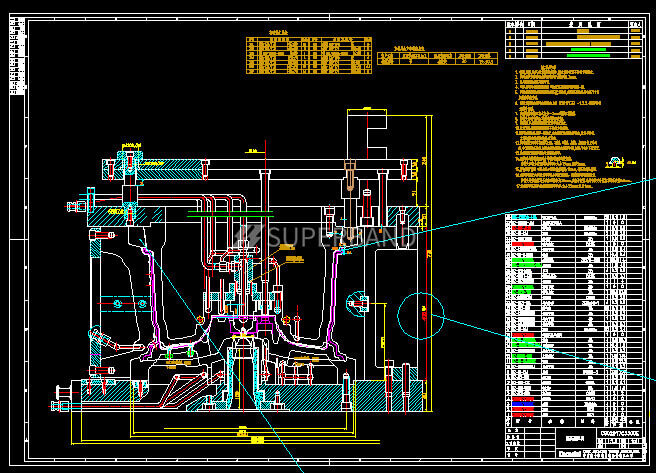

4. Mold 3D design

5. 2D

6. Prepare Mold Material

7. Rough Turning

8. Rough Milling

9. Vacuum Heat Treatment

10. Finish Turning

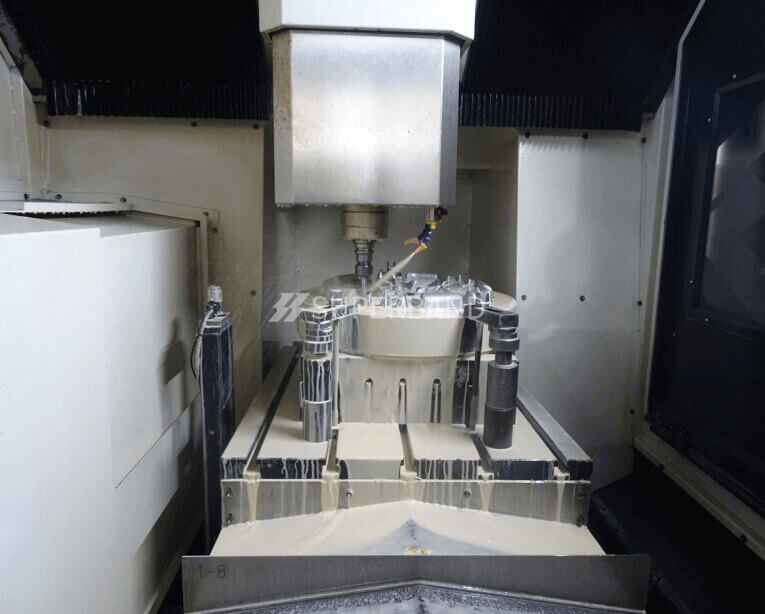

11. CNC-Milling

12. Finish Milling

13. Polishing

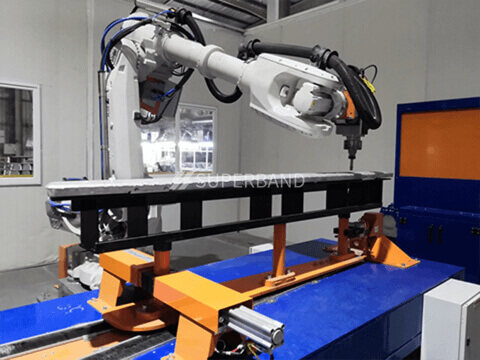

14. 3D Detection

15. Assembly

16. Packing & Delivery

Invest in the future of automotive wheel manufacturing with Superband's Gravity Aluminum Auto Wheel Mold. Streamline your production process, enhance product quality, and exceed customer expectations. Place your order today and join the ranks of industry leaders.

There will have strict gravity wheel mold simulation before shipment, which can guarantee the quality.

After receiving the molds, if there is any technical problem, our professional technical team can go to for your technical support on site.

Superband provide the management of mold’s whole life from mold design, Material research,mold manufacturing ,quality control, mold simulation, on-site technical support and after sales service.