2024-03-04

In the realm of automotive design, every detail counts, and one of the most critical components defining a vehicle's aesthetics and performance is its wheels. The Superband Automotive Wheels Mold stands at the forefront of revolutionizing wheel manufacturing techniques, delivering superior quality, durability, and style. From low-pressure casting to forging aluminum alloys, the Superband mold encompasses a spectrum of innovative methods to cater to the diverse demands of the automotive industry.

● Low-pressure casting offers a cost-effective solution while maintaining high-quality standards.

● Utilizes a controlled environment to ensure precise molding and reduced defects.

● Enables intricate designs and lightweight constructions, enhancing both performance and aesthetics.

● Ideal for mass production without compromising on durability or structural integrity.

● A cutting-edge technique combining casting and forging processes for unparalleled strength-to-weight ratio.

● Utilizes high-pressure rollers to form the wheel's shape, enhancing material density and strength.

● Provides flexibility in design, allowing for intricate patterns and unique finishes.

● Offers exceptional performance benefits, including improved handling, reduced weight, and increased durability.

● Traditional methods are characterized by simplicity and reliability.

● Molten aluminum is poured into a mold under the force of gravity, allowing for a solid, uniform structure.

● Suitable for producing robust wheels capable of withstanding heavy loads and harsh conditions.

● Offers versatility in design and finish, catering to a wide range of vehicle types and styles.

● The pinnacle of strength and performance in wheel manufacturing.

Involves shaping heated aluminum alloy under high pressure to achieve superior material integrity.

● Produces wheels with exceptional load-bearing capacity, ideal for high-performance vehicles and off-road applications.

● Allows for precise customization and optimization of wheel characteristics, including weight reduction and enhanced aerodynamics.

Uncompromising quality: Each mold variant adheres to rigorous quality control standards, ensuring consistency and reliability.

Enhanced performance: From lightweight constructions to superior material strength, Superband wheels elevate vehicle performance across various metrics.

Aesthetic versatility: With an array of design options and finishes, Superband wheels cater to diverse stylistic preferences, complementing any vehicle with elegance and flair.

Durability and reliability: Engineered to withstand the rigors of daily driving and adverse conditions, Superband wheels offer peace of mind and longevity to discerning motorists.

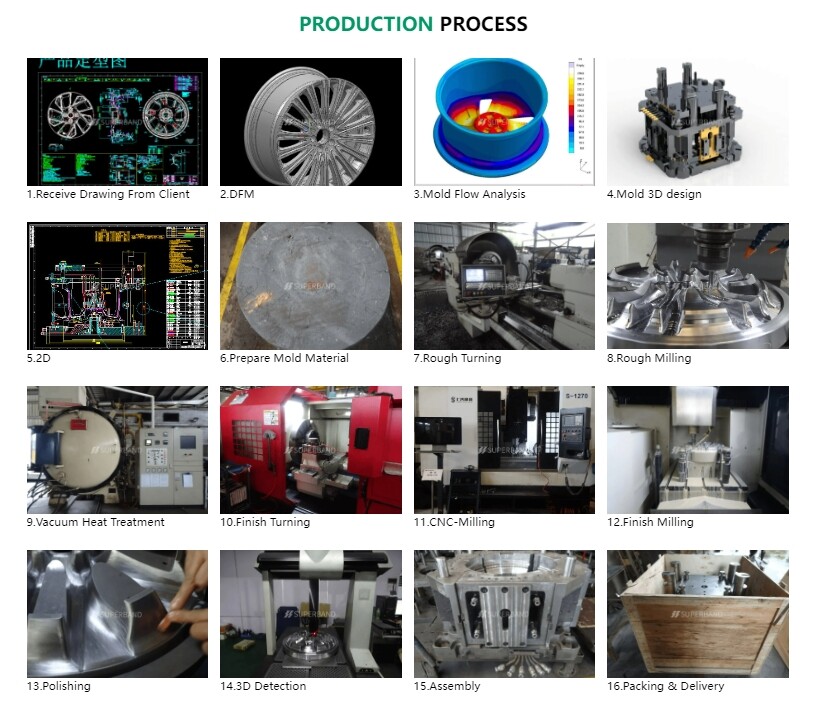

1. Receive Drawing From Client

2. DFM

3. Mold Flow Analysis

4. Mold 3D design

5. 2D

6. Prepare Mold Material

7. Rough Turning

8. Rough Milling

9. Vacuum Heat Treatment

10. Finish Turning

11. CNC-Milling

12. Finish Milling

13. Polishing

14. 3D Detection

15. Assembly

16. Packing & Delivery

As automotive technology continues to advance, the demand for wheels that marry performance, style, and sustainability will only intensify. The Superband Automotive Wheels Mold stands poised to meet these evolving needs, leveraging innovation and expertise to redefine the standards of excellence in wheel manufacturing. From eco-friendly materials to advanced manufacturing techniques, the future of Superband wheels promises to drive automotive design forward, inspiring enthusiasts and industry professionals alike.

In the competitive landscape of automotive design, every detail matters, and the choice of wheels plays a pivotal role in defining a vehicle's identity and performance. The Superband Automotive Wheels Mold represents a culmination of craftsmanship, innovation, and engineering excellence, offering motorists unparalleled quality, durability, and style. From low-pressure casting to forging aluminum alloys, Superband molds embody a commitment to pushing the boundaries of possibility, ensuring that every journey is a testament to automotive excellence.