Forging Aluminum Alloy Auto Wheel Mold

Forged Wheel Mold Casting uses the ultra-high pressure tooling to stamp the whole metal into molding one-time, which pressure can be up to 4000kg/cm.

The wheel hub made by forged wheel mold making has a better density and no pores, and the weight is more than 20% lighter than the casting parts of the same size. Forged wheel mold casting endurance is far beyond the casting parts, so forged wheel mold tools are more expensive.

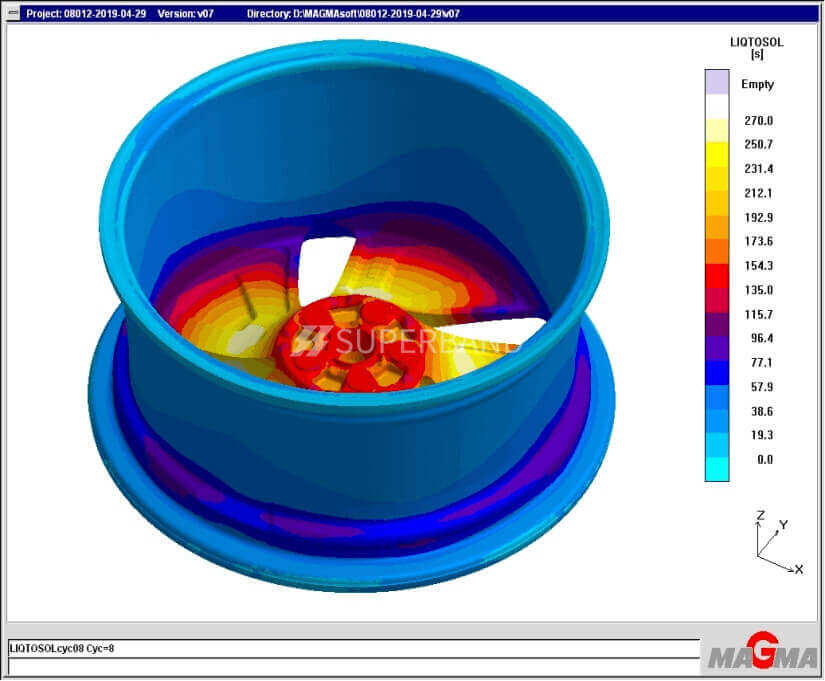

Superband Forging Aluminum Alloy Auto Wheel Mold, meticulously crafted to meet the exacting standards of automotive manufacturing.

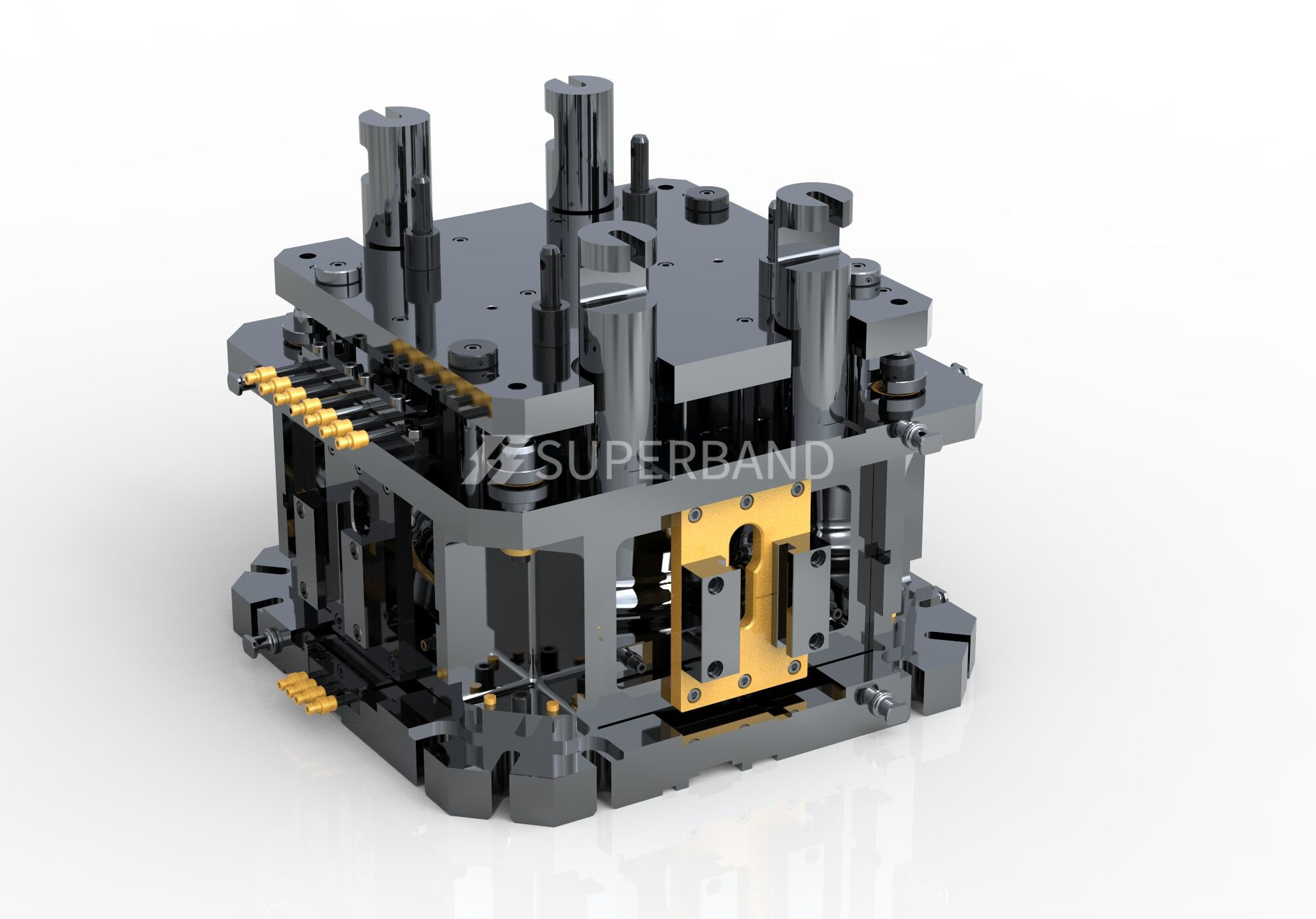

Key Features

● Superior Strength

● Precision Forging

● Heat-Treated for Performance

● Customizable Design

● Enhanced Surface Finish

Benefits of Superband Forging Aluminum Alloy Auto Wheel Mold

Increased Efficiency: Streamline your manufacturing process with our high-performance wheel mold, reducing production times and costs.

Consistent Quality: With precise engineering and quality control measures, our mold delivers consistent and reliable auto wheels that meet industry standards.

Versatile Applications: Suitable for a wide range of automotive designs and models, our mold offers versatility and adaptability to diverse manufacturing needs.

Long-lasting Durability: Built to withstand heavy-duty use, our mold is designed to maintain its integrity and performance over countless production cycles.

Expert Support: Backed by Superband's commitment to excellence, our team provides expert guidance and support to ensure optimal mold performance and customer satisfaction.

Superband is not only a forged wheel mold maker but also a solution provider of aluminum alloy casting issues. We can provide one package service.

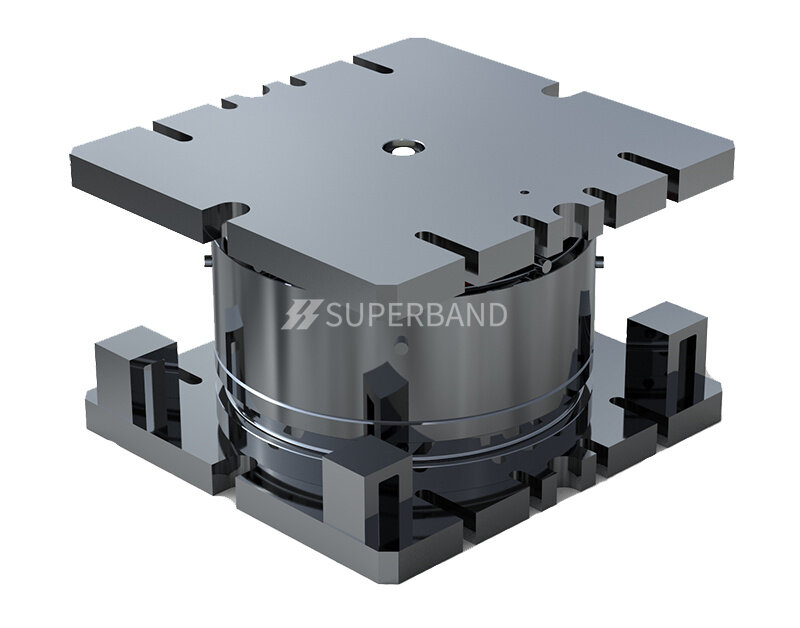

Flow Forming Mold

Forging Mold

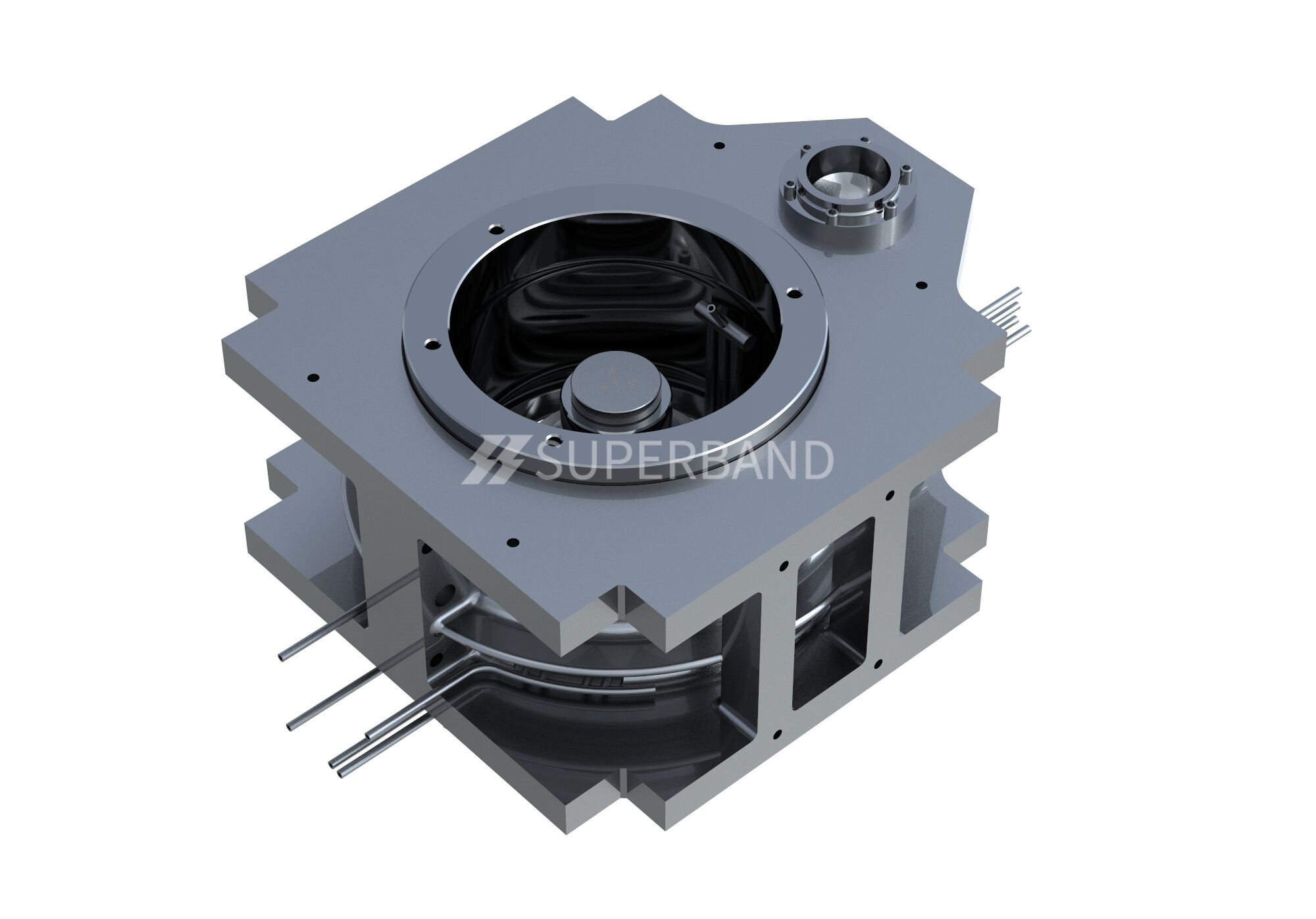

Gravity Mold

Low Pressure Water Cooling

Experience the Superband difference with our Forging Aluminum Alloy Auto Wheel Mold – the quality solution for precision wheel manufacturing in the automotive industry. Unlock new possibilities and elevate your production capabilities with Superband today!

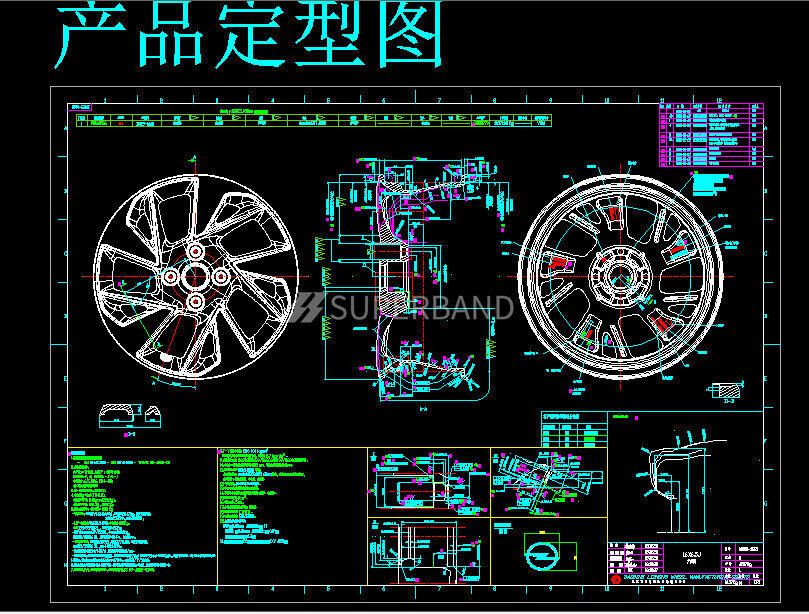

1. Receive Drawing From Client

2. DFM

3. Mold Flow Analysis

4. Mold 3D design

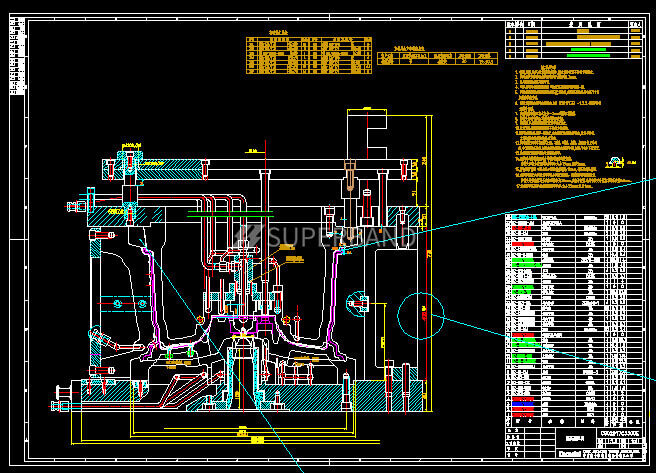

5. 2D

6. Prepare Mold Material

7. Rough Turning

8. Rough Milling

9. Vacuum Heat Treatment

10. Finish Turning

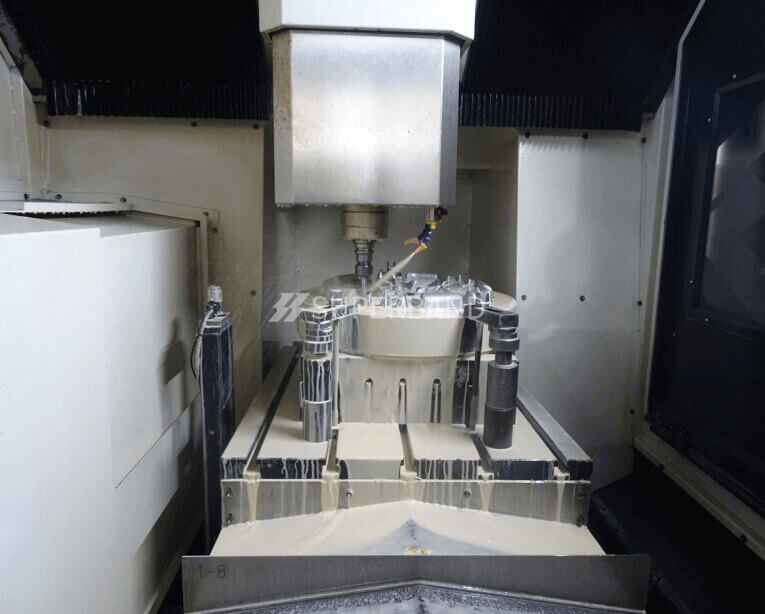

11. CNC-Milling

12. Finish Milling

13. Polishing

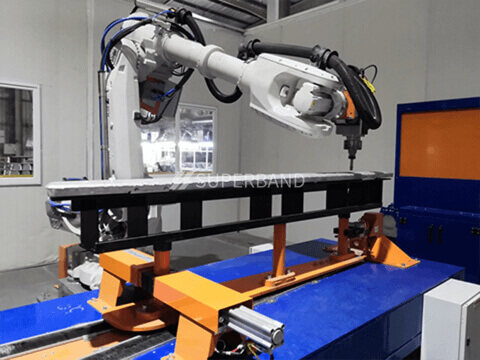

14. 3D Detection

15. Assembly

16. Packing & Delivery

There will have strict mold simulation before shipment, which can guarantee the quality.

After receiving the molds, if there is any technical problem, our professional technical team can go to for your technical support on site.

Superband provide the management of mold’s whole life from mold design, Material research ,mold manufacturing ,quality control, mold simulation, on-site technical support and after sales service.