Views: 0 Author: Site Editor Publish Time: 2025-07-11 Origin: Site

Hot dip galvanized steel is made by covering steel with zinc using a hot-dip process. This gives the steel a strong shield that stops rust and helps it last longer. The zinc sticks tightly to the steel, so galvanized steel is very tough. Many industries like hot dip galvanized steel because it does not rust easily. Car and building companies use it for frames, beams, and chassis parts.

Industry Segment | Applications of Hot Dip Galvanized Steel | Market Insights & Revenue Contribution |

|---|---|---|

Construction | Building frames, bridges, beams, columns, trusses | This is the biggest segment in the U.S.; used a lot because it stops rust |

Automotive | Outer body panels, seat frames, structural parts | Second biggest segment; rust protection is very important here |

General Industrial | Enclosures, cabinets, housings, conveyor systems | Makes up over 11% of all sales in 2023 |

Chemical, Petrochemical, Energy | Used in places with lots of rust where long-lasting protection is needed | These are special areas that need rust protection |

The world market for hot dip galvanizing was about USD 100.36 billion in 2024. Car and building companies helped this market grow. Superband’s die casting mold and alloy wheel mold products help these industries by making strong and exact parts every time.

Hot dip galvanized steel has a thick zinc layer. This layer keeps steel safe from rust and harm. It helps the steel last much longer outside and in hard places.

The hot-dip galvanizing process starts with cleaning the steel. Then, the steel gets dipped in melted zinc. After that, workers check the coating to make sure it is strong and even.

This steel is used a lot in building, cars, and factories. It saves money because it needs less fixing and care.

Picking the right coating thickness is important. Thinner coatings are better for parts that need to bend. Thicker coatings protect better against rust.

Hot dip galvanized steel can be welded and shaped if cleaned well. Following quality rules makes sure the products last a long time.

Galvanized steel is steel with a metal layer, usually zinc, on top. This layer keeps the steel safe from rust and damage. Moisture and chemicals cannot hurt the steel as easily. There are different ways to make galvanized steel. The most common way is hot-dip galvanizing. First, workers clean the steel. Then, they dip it in melted zinc. The zinc and iron in the steel react together. This makes strong zinc-iron alloy layers. These layers become part of the steel. They make it hard for rust to start.

There are many kinds of galvanized steel you can buy. Hot-dip galvanized steel is the most popular. It has a thick and tough coating. Other types are electrogalvanized steel and galvalume. Electrogalvanized steel uses electricity to put a thin zinc layer on steel. Galvalume mixes zinc and aluminum for extra strength. Galvanneal is made by heating galvanized steel. This gives it a smooth and hard surface. Each type is used for different things. Hot-dip galvanized steel is best for strength and long life.

Type of Galvanized Steel | Standards | Zinc Coating Thickness | Typical Uses | Notes |

|---|---|---|---|---|

Hot-dip galvanized steel sheet | ASTM A653, JIS G3302 | 45-275 µm | Building facades, automotive parts | Thick, strong coating |

Hot-dip galvanized steel pipe | ASTM A53, EN 10240 | 60-150 µm | Water pipes, structural uses | High corrosion resistance |

Electrogalvanized steel | ASTM A879 | 5-25 µm | Appliances, car panels | Thin, smooth coating |

Galvalume | ASTM A792 | 20-150 µm | Roofing, siding | Zinc-aluminum alloy |

Hot-dip galvanizing does not change how strong or flexible steel is. Yield strength, tensile strength, and ductility stay almost the same. Most structural steels keep their strength and bend easily. The zinc coating gives great protection from rust. This makes hot-dip galvanized steel a top pick for outdoor and factory use. The zinc layer looks shiny at first. Over time, it turns a dull gray.

Note: Hot-dip galvanized steel can last 20 to over 75 years. How long it lasts depends on where it is used. This makes it a smart pick for bridges, buildings, and car parts that need to last a long time.

Many people ask if hot dip galvanized and hot dipped galvanized steel are different. In the industry, both words mean the same thing. Both are steel dipped in melted zinc to make a thick, strong coating. This is called hot-dip galvanizing or hot-dip galvanization. The finished steel has a rough, dull surface with spangles.

Hot-dip galvanizing makes a strong bond between zinc and steel. This bond forms layers of zinc-iron alloy. These layers protect steel from rust, even if scratched. Electrogalvanized steel uses electricity to put on a thin, smooth zinc layer. This layer does not stick as well and wears off faster in tough places.

Aspect | Hot-Dipped Galvanized Steel | Electrogalvanized Steel |

|---|---|---|

Process | Dipped in molten zinc | Zinc applied by electricity |

Coating Thickness | Thick, rough, protective | Thin, smooth, less protective |

Appearance | Matte, textured, spangled | Shiny, smooth |

Corrosion Resistance | Very high | Lower |

Durability | Long-lasting | Less durable |

Painting | Needs more prep | Easier to paint |

Cost | Higher, better long-term value | Lower, for light-duty use |

Hot-dip galvanized steel is best for outdoor structures, bridges, and car parts. The thick zinc layer stands up to rain, snow, and chemicals. Electrogalvanized steel is good for indoor use or where looks matter more than strength. Hot-dip galvanization gives better protection and lasts longer. This makes it the best choice for heavy jobs.

Superband uses hot-dip galvanized steel to make die casting mold and alloy wheel mold. These products need to be strong and resist rust. This is important for car and building companies. Hot-dip galvanizing helps molds and parts last longer and work better, even in tough places.

Hot-dip galvanizing keeps steel strong and flexible.

The zinc layer protects from rust and harm.

Hot-dip galvanized steel is great for die casting mold, alloy wheel mold, and other factory uses.

️ Tip: When picking galvanized steel, always check the coating thickness and type. Hot-dip galvanized steel gives the best protection for outdoor and tough jobs.

Hot-dip galvanizing keeps steel safe from rust for a long time. The process has three main steps: surface preparation, zinc coating application, and inspection. Each step helps make a strong protective layer. Superband Mould uses new technology and checks quality carefully. This makes sure every product meets industry rules.

Surface preparation is the first and most important step. Workers clean the steel to take off dirt, oil, paint, and rust. If the steel is not very clean, zinc will not stick well. This can leave bare or weak spots in the coating. Paint and lacquer are hard to remove with chemicals. Workers use abrasive blasting to get rid of these coatings. Welding spatter and sand from castings must also be cleaned off. If not removed, these things can cause lumps, rough spots, or bare patches.

Contaminant | Effect on Coating Quality | Removal/Prevention Method |

|---|---|---|

Paint, Oil, Wax, Lacquer | Cause ungalvanized bare spots and poor zinc adhesion; surface defects may require repair or rejection. | Mechanical removal (abrasive blasting) necessary; chemical cleaning insufficient. |

Welding Spatter | Creates lumps in coating; coating does not adhere well and can be easily removed, leading to bare spots. | Remove welding residues before galvanizing. |

Sand Inclusions in Castings | Causes rough or bare spots; not removed by acid pickling. | Abrasive cleaning at foundry before galvanizing. |

Welding Blowouts | Bare spots around welds caused by trapped pretreatment liquids boiling out during galvanizing. | Ensure complete welds; preheat to dry overlap areas. |

Surface Rust and Excessive Pitting | Leads to uneven pickling and coating; may cause over-pickling of new surfaces. | Abrasive blast cleaning for uniform coating. |

Special machines help with surface preparation. Degreasing baths take off oil and dirt. Acidic pickling baths remove rust and mill scale. Flux tanks add a layer to stop new rust before the zinc bath. Clean steel helps zinc stick well during galvanizing.

Stage | Description | Typical Equipment Used |

|---|---|---|

Surface Preparation | Includes degreasing (removal of dirt, oil), acidic pickling (removal of oxides and burrs), fluxing (applying protective layer to prevent oxidation) | Degreasing baths, acidic pickling baths, flux tanks |

After cleaning, the steel goes to the zinc coating step. Workers dip the steel in hot, melted zinc at about 450°C. This step makes a strong bond between zinc and steel. The bond forms layers of zinc-iron alloy and a pure zinc layer on top. The coating thickness depends on the zinc bath’s heat and how long the steel stays in.

Temperature Range (°C) | Coating Phase Composition | Coating Thickness (μm) |

|---|---|---|

520–555 | Fully alloyed coatings with microporous ζ-alloy crystals embedded in S and ζ-alloy solid solution | Thickness decreases from ~80 μm at 520 °C to ~20 μm at 555 °C; max ~100 μm at 530 °C |

Lower end (520 °C) | Well-defined ζ layer on top of δ layer | Thicker coating |

Higher end (555 °C) | Primarily δ phase with reduced ζ phase | Thinner coating |

The bond has a thin inner layer called the Γ-Fe3Zn10 phase. This layer helps the coating stay strong and last long. The outer zinc layer, called the η phase, gives the best rust protection. Thicker zinc coatings usually protect better. Hot-dip galvanizing makes a coating that lasts for many years, even in tough places.

There is also a post-treatment step. Workers cool the galvanized steel in water or with air. This step makes the coating hard and controls how it looks.

Stage | Description | Typical Equipment Used |

|---|---|---|

Galvanizing | Immersion of workpieces in molten zinc bath (~450°C) to form zinc-iron alloy layers and pure zinc outer layer | Galvanizing kettle (molten zinc bath) |

Post-Treatment | Cooling/quenching of galvanized workpieces either by water quench or air blower to harden coating and control finish | Quench tanks, air blowers |

Note: The thickness of the zinc coating is very important for stopping rust. Thicker coatings last longer, but the way the layers are made also matters.

Inspection and quality checks are the last steps. Inspectors look at the galvanized steel to make sure the coating is even, thick enough, and has no problems. They use different ways to test the coating:

Inspection Method | Description | Quality Benchmark / Standard |

|---|---|---|

Visual Inspection | Assess appearance, finish, and identify uncoated areas | ASTM A123, A153, A767 specifications |

Coating Thickness Measurement | Use of eddy current gauges or magnetic thickness gauges to measure zinc coating thickness | ASTM coating thickness requirements |

Adhesion Tests | Cross-hatch test, bend test, peel test to verify coating adherence | ASTM standards and AGA guidelines |

Corrosion Resistance Test | Salt spray (Neutral Salt Spray, NSS) test to simulate long-term corrosion resistance | ASTM corrosion resistance criteria |

Hardness Testing | Rockwell and Vickers hardness tests to assess mechanical durability | Industry-accepted hardness values |

Microscopic Cross-Section | Cutting and polishing samples to examine coating structure, thickness, and bond integrity | ASTM and AGA inspection guides |

Inspectors use tools like magnetic thickness gauges and ultrasonic devices to check the zinc layer. They do adhesion tests, like cross-hatch and bend tests, to see if the coating sticks well. Salt spray tests show how well the coating fights rust over time. Hardness tests check how tough the coating is. Looking at the coating under a microscope helps inspectors see the layers and check the bond.

Eddy current gauges give exact thickness numbers.

Cross-hatch and bend tests check if the coating sticks well.

Salt spray tests show how the coating handles rust.

Hardness tests check how strong the coating is.

Microscopic checks show the coating’s layers and quality.

Superband Mould uses these tests to make sure every die casting mold, alloy wheel mold, and other products are high quality. The company follows world rules like ASTM and AGA guidelines. This careful work makes sure every product protects well and lasts a long time.

️ Tip: Always pick galvanized steel with the right coating thickness and quality checks for your job. Good hot-dip galvanizing gives the best protection for cars, buildings, and factories.

Hot dip galvanized steel is very good at stopping rust. The zinc coating makes a shield that keeps out water, chemicals, and bad weather. The American Galvanizers Association says this steel works well in salty water, factories, and chemical places. In seawater, magnesium and calcium slow down rust. A film forms on the zinc when the pH is between 4.0 and 12.5. Studies show that in dirt and factory air, the zinc layer makes things like ZnO and zinc hydroxycarbonates. These build up and help stop rust even more. But, heat and some chemicals can make rust happen faster. So, it is important to check the steel often.

Hot dip galvanized steel is strong and lasts a long time. Research shows steel thicker than 1/4 inch can last about 72 to 73 years outside before it needs fixing. This is because the zinc slows rust to about 1/30th of bare steel. In dirt, it can last 30 years in bad soil or over 120 years in good soil. Inside, where there is less rust, it lasts even longer. This makes it great for die casting mold and alloy wheel mold that need to work for many years.

Hot dip galvanized steel saves money over time. The starting price is good, but the real savings come from not needing much care and lasting a long time. The table below shows how much different coatings cost over 20 years:

Coating System | Initial Cost ($/ft²) | Total Lifecycle Cost ($) |

|---|---|---|

Hot Dip Galvanizing | 1.76 | 214,500 |

Epoxy/Epoxy Paint | 2.92 | 2,595,500 |

Epoxy/Polyurethane Paint | 3.35 | 3,031,500 |

Inorganic Zinc/Epoxy | 3.17 | 1,996,000 |

Duplex System (Galv + Paint) | 5.28 | 1,142,000 |

Metallizing | 8.37 | 3,140,000 |

Taking care of hot dip galvanized steel is easy. Just look at it often, wash with plain water, and do not use rough tools. Most things made with it need almost no fixing for many years. This makes it a smart and safe choice for Superband’s customers.

️ Tip: Pick hot dip galvanized steel if you want your project to stay strong and not need much care.

Coating thickness is very important for how hot dip galvanized steel works. Thicker coatings protect better from rust. But, they can change the steel’s strength in some uses. If the coating is thick on strong steel, it can make the steel wear out faster. Cracks can start in the coating and move into the steel. When steel bends or moves a lot, thick coatings get more cracks inside than thin ones. Computer tests show thick coatings have more force that makes cracks grow. Thin coatings stay safer and do not crack as much. For things like die casting mold or alloy wheel mold, picking the right coating thickness is important. It helps keep the steel strong and safe for a long time.

Thick coatings can lower how long strong steel lasts.

More cracks happen in thick coatings when steel moves a lot.

Thin coatings are better at stopping cracks from growing.

Tip: Thin coatings are often better for parts that bend or move a lot.

Good ways of making and welding help keep the zinc coating strong. Superband has some tips for working with hot dip galvanized steel. Use welding rods that match the steel to keep the coating looking nice. Clean off all welding dirt before galvanizing to stop coating problems. Do not use tight joints, because they can trap chemicals and cause rust. If you must use overlapping joints, seal them well and add vents or small gaps. Grind cut edges before galvanizing for a smooth finish. Plan where to lift the parts so the coating does not get marked. Make sure parts have vents and drains so cleaning and zinc can flow everywhere. Working together early helps fabricators, galvanizers, and engineers get the best results for die and mold products.

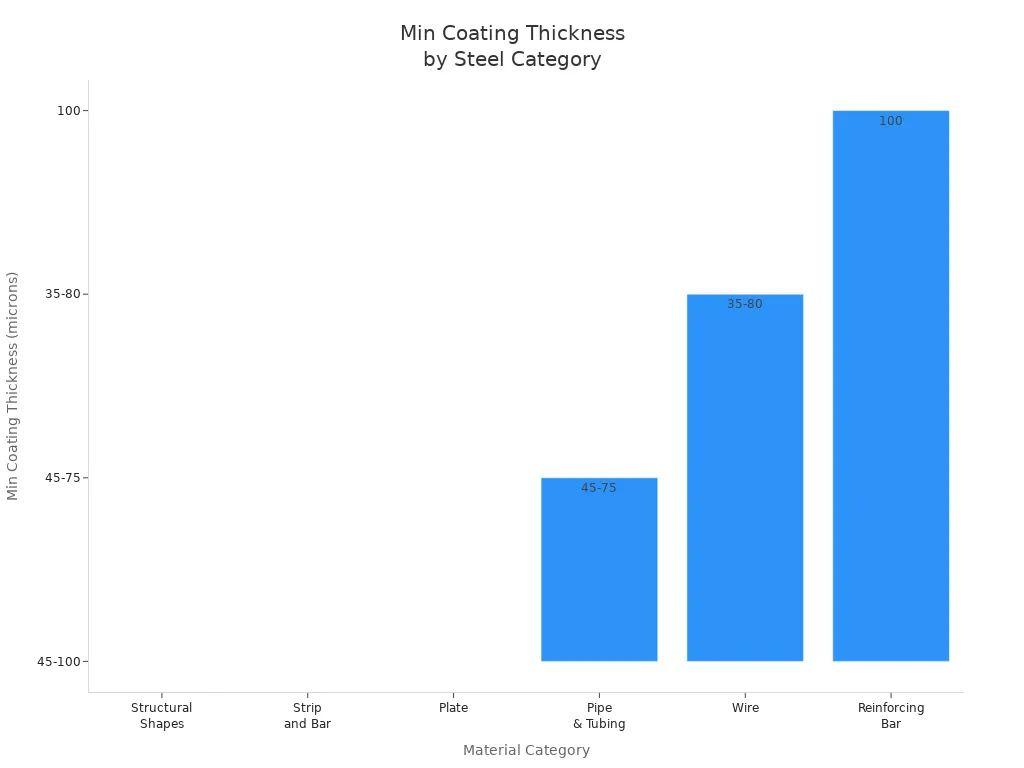

Hot dip galvanized steel must follow strict rules to be good and last long. The ASTM A123/A123M standard is the most well-known. It tells how thick, smooth, and nice the coating should be. This rule is for many steel shapes like bars, plates, pipes, tubes, wire, and reinforcing bar.

Material Category | Minimum Coating Thickness (microns) |

|---|---|

Structural Shapes | 45–100 |

Strip and Bar | 45–100 |

Plate | 45–100 |

Pipe & Tubing | 45–75 |

Wire | 35–80 |

Reinforcing Bar | 100 |

These rules say the coating must be smooth and even, with no bad spots. Workers check the steel at the plant to make sure the coating is thick enough and sticks well. Following these rules helps Superband’s die casting molds and alloy wheel molds work well and last a long time.

Car makers use hot-dipped galvanized steel for many important parts. They use it in chassis, body panels, and exhaust systems. The zinc coating keeps cars safe from road salt and wet weather. This helps cars last longer and stay safer. Cars need fewer repairs because of this protection. Superband Mould makes die casting mold and alloy wheel mold with galvanized steel. These molds help make car parts that fit well and do not rust. Using hot-dipped galvanized steel helps cars be lighter and work better. Superband makes sure every mold is high quality and lasts a long time.

Hot-dipped galvanized steel is very important in building things. Builders pick it because it stops rust and needs little care. The zinc and steel together make a strong shield. This shield stands up to rain, dirt, and concrete. In big projects, you see galvanized steel in bridges and highways. It is used for guardrails, light poles, signs, bolts, and walls. This steel is strong and does not rust, so it is good for things that must last many years. It also lets builders make new designs and looks modern. You can recycle it, which helps the environment.

Note: Using galvanized steel in buildings keeps people safe and saves money over time.

Many other businesses use hot-dipped galvanized steel too. People who make home appliances use it for cases and cabinets. Phone companies use it for towers and frames. Medical equipment makers like it because it is clean and works well. Superband Mould gives these companies good die casting mold and metal injection mold. The zinc coating keeps parts strong and stops rust, even in tough places. Because it can be used in many ways, galvanized steel is a great pick for lots of jobs.

Many companies use different ways to protect steel. The two most common are hot dip galvanizing and electro-galvanizing. Hot dip galvanizing puts a thick zinc layer on steel. This happens because of a chemical reaction. The thick layer gives strong protection from rust. Electro-galvanizing uses electricity to add a thin zinc layer. This thin layer looks smooth and shiny. It is good for things used inside or where looks matter.

The table below shows how these two ways are different:

Aspect | Hot-Dip Galvanizing | Electro-Galvanizing |

|---|---|---|

Coating Thickness | Thick zinc layer, 3-5 times longer service life | Thin zinc layer, less durable outdoors |

Durability | Excellent corrosion resistance, minimal maintenance | Good for indoor use, less effective outdoors |

Cost | Cost-effective for large, long-term projects | Lower initial cost, may need extra coatings |

Appearance | Silvery, grainy finish | Smooth, shiny finish |

Application | Construction, infrastructure, outdoor uses | Automotive, home appliances, decorative uses |

Hot dip galvanizing is best for bridges and outdoor things. It lasts a long time in tough weather. Electro-galvanizing is better for car parts and home items that need to look nice. Superband uses hot dip galvanizing for die casting mold and alloy wheel mold. This helps the molds last longer and stay strong.

️ Tip: Pick the right galvanizing method for your project. Think about where and how the steel will be used.

Painting is another way to keep steel safe. Zinc-rich paint gives some protection but does not stick to steel as well as hot dip galvanizing. Hot dip galvanizing makes a strong bond with the steel. It protects by blocking rust and by giving up zinc if needed. Zinc-rich paint mostly blocks rust but does not last as long. It works best if the paint has a lot of zinc and sticks well.

Here is a table to show how these two ways compare:

Aspect | Hot Dip Galvanizing | Zinc-Rich Painting |

|---|---|---|

Bonding to Steel | Metallurgical bond | Surface adhesion |

Protection Type | Barrier + sacrificial | Mostly barrier |

Durability | Up to 50 years or more | 12-15 years |

Application Location | Factory only | Field or factory |

Maintenance | Minimal | Needs more frequent upkeep |

Hot dip galvanizing is best for steel that needs to last a long time. It is good for big projects and die and mold products. Zinc-rich paint is easier to use on-site but does not last as long. Sometimes, both ways are used together to make steel even stronger.

Note: Hot dip galvanizing is best for outdoor and heavy jobs. Painting is good for quick fixes or when you cannot use factory galvanizing.

Hot dip galvanized steel stops rust and lasts many years. Workers clean the steel and dip it in hot zinc. This makes a hard coating that can fix itself if scratched. The main benefits are that it lasts long, needs little care, and saves money. Many businesses use it for important parts. Car makers, builders, and energy companies use it for things like die casting molds and alloy wheel molds.

The zinc layer covers all shapes and is very tough.

Hot dip galvanizing follows strict rules for strength and quality.

To get the best results, experts should:

Think about what the project needs and pick the right coating thickness.

Talk to experts like Superband for special help and advice.

To learn more, check out the American Galvanizers Association or ask Superband for custom mold help and product tips.

Hot dip galvanized steel stops rust and damage. The zinc coating makes a tough shield. This helps steel last longer, even in rough places. Many companies pick it because it is strong and easy to take care of.

Superband uses hot dip galvanized steel for die casting molds and alloy wheel molds. These molds need to be strong and not rust. The zinc coating helps each mold work well and last longer, even when used a lot.

Yes, workers can weld or shape hot dip galvanized steel. They need to clean the steel before and after welding. Cleaning helps keep the zinc coating strong and gives a smooth finish.

Industries use hot dip galvanized steel in building, cars, and home appliances. Builders use it for bridges and frames. Car makers use it for chassis and panels. Appliance makers use it for strong housings.

Hot dip galvanized steel can last 20 to over 75 years outside. How long it lasts depends on where it is used and how thick the coating is. Checking it often helps keep its protection strong.

️ Tip: For custom die casting mold help, contact Superband for expert advice and support.