Views: 0 Author: Site Editor Publish Time: 2026-02-02 Origin: Site

Ever wonder how a metal part comes out smooth and exact? Aluminum die casting does it by forcing molten alloy into a steel die fast.

In this article, we explain what aluminum die casting is, how the cycle works, and why buyers choose it. You will learn key pros, limits, common defects, and simple DFM rules.

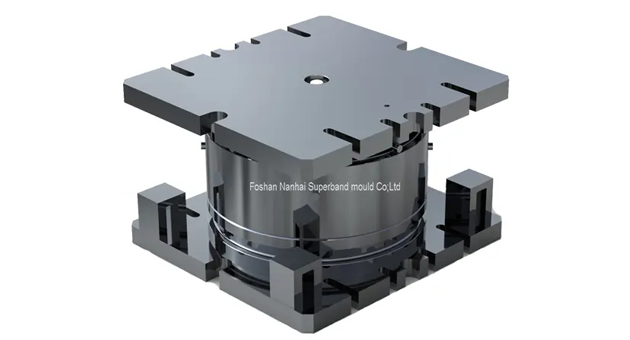

Aluminum die casting uses a reusable steel die set. It has a fixed half and a moving half. They close under strong clamp force before injection starts. Inside, you may see cores, slides, and ejector pins. They form holes, undercuts, and internal features. After cooling, the press opens and ejectors push the part out. The die then closes again for the next shot. This repeated cycle drives high output and stable dimensions. Die design also sets draft, parting lines, and cosmetic faces. Those choices affect both quality and cost over time.

The process begins at the melt station. Operators control alloy chemistry and cleanliness. They remove dross and limit oxides before transfer. Then they dose a measured amount into the shot sleeve. Cold-chamber machines use ladling for this step. It keeps hot melt away from machine internals. Good dosing is more than volume control. It also reduces air pickup and temperature drift. If dosing varies, fill behavior changes across shots. That can raise scrap even when the die stays stable. Buyers should ask how the supplier tracks melt temperature and metal handling steps.

Next, a plunger drives the melt into the die cavity. It accelerates fast to complete filling before freezing. Pressure then holds metal during early solidification. This helps reduce shrinkage issues in many shapes. Cooling channels remove heat in a controlled way. The goal is stable cycle time and stable die temperature. If the die runs too hot, soldering can rise. If it runs too cold, cold shuts can appear. Once the part reaches ejection strength, the press opens. Ejector pins then release the casting. Process settings must match the die design and the alloy choice.

After ejection, the part still has gates and overflow features. Trimming removes these features for clean edges. Some parts need machining for threads or precision datums. Many die cast parts need little machining when DFM is strong. Finishing depends on function and appearance targets. It may include shot blasting, anodizing, painting, or powder coating. If the part needs sealing, leak tests may follow. Secondary ops often decide the true unit cost. So we should design for minimal rework and stable trimming. A good supplier will propose changes that reduce machining time and scrap.

Tip: Ask for a full cycle map, not only a sample photo.

Sand casting uses a disposable mold and gravity fill. It supports large parts and low volumes well. Yet its surface finish is rougher and tolerances are wider. Aluminum die casting uses steel dies and fast press cycles. That creates better repeatability and higher output. The trade-off is higher upfront tooling cost and longer tooling lead time. If your volume is low, sand casting may win on cost. If your volume is high, aluminum die casting can win on unit cost. Buyers should compare total cost across expected annual demand. They should also compare machining and finishing needs across both options.

Permanent mold casting also uses a reusable metal mold. It usually fills by gravity rather than high pressure. Gravity fill can reduce some gas issues, depending on design. Yet it may struggle on very thin walls or long flow lengths. Aluminum die casting forces metal into the cavity faster. That supports intricate shapes and thinner ribs. It also supports higher automation and faster cycles. The trade-off is higher pressure on the die, so wear rises. You may also see parting lines and ejector marks. If thin walls and high output matter, die casting often fits better. If moderate complexity matters, permanent mold can compete.

Investment casting can create complex shapes and fine details. It can also reduce draft limits compared to die casting. Yet it uses disposable shells, so cycle time is longer. It also tends to cost more per part at high volumes. Aluminum die casting shines when you need thousands of parts fast. It also delivers consistent surfaces and tight repeatability. Investment casting shines when geometry needs extreme freedom. It can handle deep internal paths and sharp features. Buyers should choose based on volume, tolerance, and material needs. If cost per part must drop at scale, die casting usually helps.

Process | Best fit | Typical strengths | Common trade-offs |

Aluminum die casting | High volume parts | Tight repeatability, fast cycles | Higher die cost, porosity risk |

Sand casting | Low volume, large parts | Low tooling cost, flexible changes | Rough finish, wider tolerance |

Permanent mold | Mid volume parts | Better finish than sand | Limits on thin walls |

Investment casting | Complex geometry | High detail, low draft needs | Higher part price, slower cycle |

Note: Choose the process after you lock volume and tolerance targets.

• Steel dies hold shape across many cycles.

• They support stable tolerances and fit.

• Automation reduces operator variation.

• Output scales fast after process lock.

• Unit cost drops as volume rises.

• Plan die rebuilds in your model.

These benefits show up after the die is stable. If you rush launch, you may see scrap spikes. A good plan includes trials, capability checks, and a clear maintenance cycle. When you budget rebuild time early, pricing stays predictable.

• Aluminum offers strong strength-to-weight.

• It can cut mass in many parts.

• Many alloys resist common corrosion.

• It moves heat well for housings.

• It conducts electricity for covers.

• Thin fins and ribs cast well.

• Alloy choice still changes performance.

These properties help parts replace heavier steel designs. They also support compact housings and heat sink features. Still, not all alloys behave the same in casting and machining. Align alloy choice to function and test needs early.

• Porosity can affect sealing and fatigue.

• Draft is required for clean ejection.

• Parting lines can affect cosmetics.

• Ejector marks may need refinishing.

• Upfront die cost is usually high.

• Frequent design changes raise cost.

• Lock geometry and inspection early.

Most “failures” come from ignoring these limits. If sealing matters, define porosity rules and leak tests upfront. If cosmetics matter, control parting lines and ejector placement. When you plan these items early, aluminum die casting stays a strong option.

Alloy selection shapes strength, flow, and corrosion behavior. A380 is a common choice for general die cast parts. It balances castability and mechanical performance for many uses. A360 can offer better corrosion resistance in some applications. A413 is often used where pressure tightness matters. B390 is known for wear resistance in some designs. Each alloy also responds differently to heat and machining. Your supplier should explain why they propose one alloy over another. They should also link it to your inspection plan. Alloy choice is not only a material decision. It is also a quality and cost decision over the part’s life.

Start by listing what the part must do in service. If it must seal, pressure tightness becomes a priority. If it must carry loads, strength and fatigue become key. If it must shed heat, thermal conductivity matters more. Then choose an alloy that matches those needs. Also consider wall thickness and flow length. Some alloys fill thin sections more easily than others. Your supplier can help using filling simulation and trial data. You should also consider machining and finishing needs. Some alloys cut cleaner and coat more consistently. When you align application needs early, alloy selection becomes simpler and safer.

Sourcing is easier when alloy supply is stable. High demand alloys may be easier to buy in large batches. Stable sourcing helps keep chemistry consistent across lots. Recycled content can reduce cost and emissions (needs verification). Yet it can raise impurity risk if controls are weak. Buyers should request chemistry limits and lot traceability. They should also ask how returns and runners are remelted. Melt practice affects hydrogen pickup and oxide levels. If you need a strict defect limit, you need strict melt control. A good supplier will show melt logs and sampling plans. Those records support stable quality as volume grows.

Alloy | Common reason to choose it | Typical application fit |

A380 | Balanced properties and castability | Housings, brackets, enclosures |

A360 | Corrosion resistance focus | Marine or hydraulic parts |

A413 | Pressure tightness focus | Fluid parts and covers |

B390 | Wear resistance focus | High wear components |

Tip: Ask the supplier to map alloy choice to your acceptance tests.

Good DFM keeps aluminum die casting stable and repeatable. Use draft for clean ejection and better cosmetics. Keep walls balanced to reduce hot spots and warpage. Add ribs for stiffness instead of thick walls. Add fillets to improve flow and lower stress. Avoid sharp corners and isolated thick bosses, since they trap shrinkage and raise crack risk. If thickness is required, use coring or ribbing to control cooling.

Parting lines affect both function and appearance. Keep them away from sealing faces and visible areas when possible. Plan ejector pins on non-cosmetic faces to reduce marks. Ensure enough draft near pin locations to prevent drag and distortion. Use slides and lifters only when needed, since they raise cost and maintenance. Lock part orientation early, because CAD changes are cheap, but steel changes are not.

Gate location controls flow direction and meeting points. Poor gates can cause cold shuts and flow lines. Vents must release air before metal seals the cavity. Poor venting increases porosity and surface defects. Place vents near last-to-fill regions and use overflows to capture cold metal and oxides. In trials, check vent clogging and gate wear, because both can drift quality over long runs.

Cast near-net bosses, ribs, and pockets to cut machining time. Define stable datums for critical fits and protect them from distortion. Avoid tight as-cast tolerances unless proven by capability data. For high-precision holes, cast pilots and machine after. Plan fixtures early to avoid redesign cost later.

Note: DFM changes save more money than late tool rework.

Defects in aluminum die casting usually follow a pattern. Porosity often links to air entrapment or feeding limits. Cold shuts can appear when fronts meet after freezing starts. Flash appears when parting faces wear or clamp force is low. Shrinkage can appear in thick areas that cool slowly. Warpage can appear when cooling is unbalanced across the part. The best approach is to link each defect to a root cause class. Then we apply the right control in design or process. We also track defect location, not only defect count. Location patterns reveal the true cause faster. If you track it well, improvement becomes repeatable.

Inspection should match the part’s true risk. Dimensional checks confirm fit and assembly function. CMM sampling works well for key datums and hole patterns. X-ray or CT can assess internal porosity when required. Leak tests help validate pressure-tight parts and covers. Yet inspection adds cost, so we use it wisely. The best plan focuses on critical features and failure modes. Buyers should define acceptance levels and sampling rules. They should also align inspection methods across suppliers. If one site uses different rules, quality comparisons become noisy. A clear plan improves supplier accountability and reduces disputes during PPAP style reviews.

Unit cost is driven by time and yield. Cycle time sets how many parts you can make per hour. Die complexity can raise both build cost and maintenance cost. More cavities raise output but can raise balancing risk. Yield loss from scrap quietly drives cost up fast. Finishing steps can also dominate cost on cosmetic parts. Machining cost depends on feature count and tolerance demands. Buyers should ask suppliers to break down these drivers. It shows where improvement will pay back most. If you only compare piece price, you miss key risks. A good quote includes cycle assumptions and yield assumptions. Then you can stress test the business case.

A good supplier can explain how they control aluminum die casting. They can show process ranges and maintenance routines. They can also show material traceability and melt controls. Ask for a trial plan that includes measurements and defect review. Ask how they handle changes and revisions after sampling. Ask what reports you will receive at each milestone. Also ask about after-sales support for die repairs and spares. That support matters more during ramp up and volume swings. Suppliers who plan spares reduce downtime risk for buyers. This is where a strong partner can protect your schedule. When you choose well, the line runs calmer and quality stays stable.

Tip: Compare suppliers using yield and downtime assumptions, not only unit price.

Buyer control | Why it matters | What to request |

Quality targets | Prevents rework surprises | Defect limits and sampling rules |

Tooling plan | Drives uptime and yield | Die layout, spares, maintenance plan |

Process window | Stabilizes cycle and defects | Injection and cooling parameter ranges |

Inspection | Protects critical functions | CMM, X-ray, leak test scope |

Documentation | Supports audits and scaling | Trial reports and traceability package |

Aluminum die casting makes precise parts fast, using reusable steel dies and controlled injection. We covered how the cycle works, why it scales well, and what limits to plan for, like porosity, draft, and upfront tooling cost.

Strong results come from smart DFM, the right alloy, and clear inspection rules. For die casting programs, Foshan Nanhai Superband Mould Co., Ltd. supports one-stop mold design and manufacturing, helping you shorten trials, improve yield, and keep output consistent at scale.

A: Aluminum die casting injects molten alloy into a steel die under pressure for fast, repeatable parts.

A: Aluminum die casting delivers stable tolerances, quick cycles, and lower unit cost after tooling pays back.

A: Aluminum die casting is faster and more precise, but it needs higher upfront die cost.

A: Aluminum die casting can show porosity, flash, cold shuts, and warpage if filling or cooling drifts.

A: Improve venting, control melt handling, and stabilize injection and die temperature in aluminum die casting.