2023-03-31

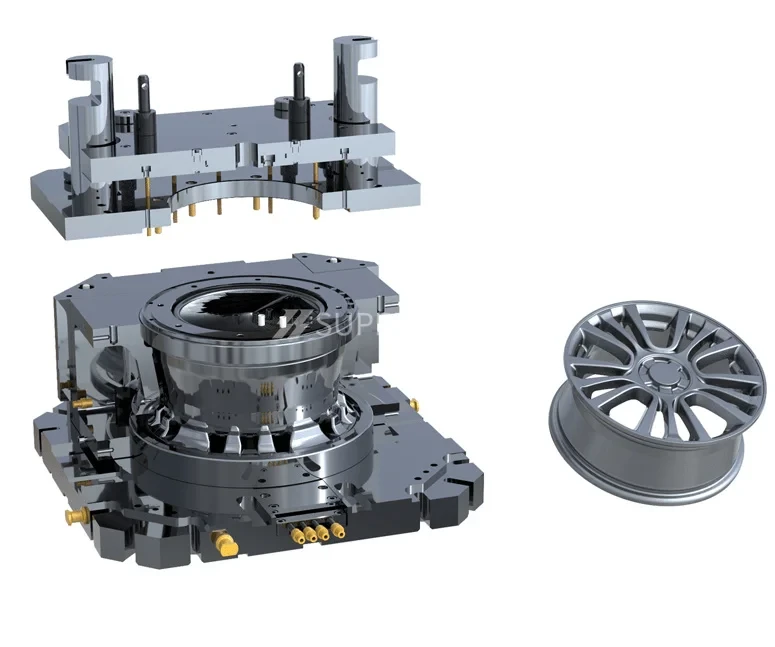

Low-pressure die casting (LPDC) is a popular casting process used to produce high-quality metal parts, including wheels.

The LPDC process involves the injection of molten metal into a die mold using low pressure. The LPDC wheel mold quality and cost are essential considerations for any manufacturer.

The LPDC wheel mold detail is a crucial factor that affects the cost of the LPDC wheel mold.

A complex mold design with multiple cavities, undercuts, and complex features requires a more intricate manufacturing process and is, therefore, more expensive to produce. Simple mold designs are less expensive to manufacture and require less material and labor.

The cost of the raw materials used in the production of the LPDC wheel mold can also impact the cost. Fluctuations in the cost of raw materials can affect the overall cost of the mold.

The material must be durable, have good thermal conductivity, and resist wear and tear.

Common materials used for LPDC wheel molds include steel, iron, and aluminum. Steel molds are the most expensive but are durable and long-lasting. Iron and aluminum molds are less expensive, but wear out faster compared to steel wheel molds.

Larger and more complex wheels require larger molds, which are more expensive to produce. The complexity of the wheel also affects the number of mold pieces required to produce the wheel, which can increase the cost.

The production volume of the wheels is a factor that affects the cost of the LPDC wheel mold. High-volume production requires a larger and more expensive mold, while low-volume production requires a smaller and less expensive mold.

The quality requirements of the final product affect the cost of the LPDC wheel mold. High-quality requirements require a more precise and high-quality mold, which is more expensive to produce.

The cost of tooling and equipment required for the production of the LPDC wheel mold can also impact the overall cost. It includes items such as cutting tools, measuring instruments, and machining equipment.

The lead time and production schedule required for the LPDC wheel mold can also affect the cost. Rush orders or tight production schedules may require additional resources and labor, which can increase the overall cost.

The relationship between the manufacturer and the supplier of the LPDC wheel mold can also impact the cost. Long-term relationships with trusted LPDC wheel mold tool suppliers may result in lower costs due to bulk orders or negotiated pricing.

Regular maintenance of the mold is necessary to ensure consistent quality and prolong its lifespan of the mold. Over time, the mold may require repairs or replacement of components, which can increase the overall cost.

Labor and material costs vary by region, and transportation costs can also impact the total cost of the mold.

Additional services such as design assistance, prototyping, and testing can add to the overall cost of the LPDC wheel mold. However, these services can also improve the quality of the final product and reduce the risk of defects.

Manufacturers should carefully consider each of these factors when determining the cost of an LPDC wheel mold. By doing so, they can ensure that they are getting the best value for their investment and producing high-quality wheels at a competitive price.