2023-03-31

When it comes to manufacturing high-quality aluminum wheels, the quality of the LPDC (Low-Pressure Die Casting) wheel mold plays a critical role in the final product.

After reading this article, you may have a deeper understanding of the importance of LPDC wheel mold quality and its influence on the final product.

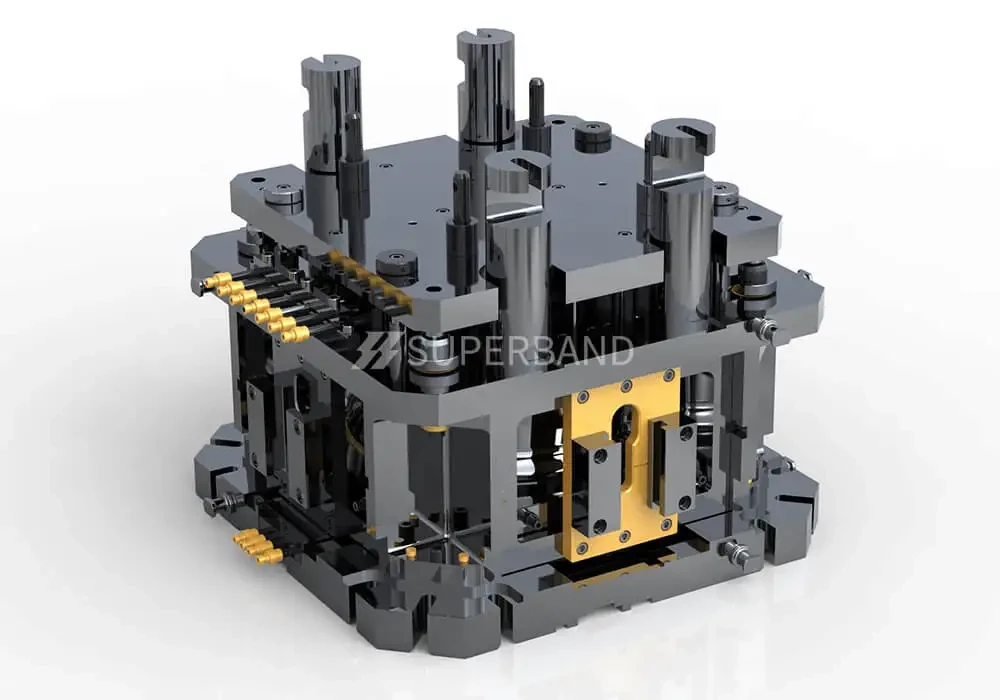

The LPDC wheel mold is a die-casting tool used to manufacture aluminum wheels. The process involves filling a mold cavity with molten aluminum and then allowing it to cool and solidify.

The LPDC wheel mold quality is critical to the final product's performance, as any defects or imperfections in the mold can result in defects in the final product.

LPDC wheel molds offer several benefits over other manufacturing methods, including:

● Higher quality final product with fewer defects

● Ability to produce high-volume production runs quickly and efficiently

● Precise control over the shape and size of the final product

● Ability to use a variety of aluminum alloys to achieve desired properties

● Lower production costs compared to other methods, such as forging or machining.

The quality of the LPDC wheel mold affects the final product in several ways, including its performance, appearance, and durability.

● Poor-quality wheel mold can result in defects in the final product, such as porosity, surface defects, and dimensional inaccuracies.

● Porosity can occur due to improper venting or gating of the mold, resulting in trapped air pockets that weaken the structure of the wheel.

● Surface defects such as cracks, pits, and scratches can occur due to mold wear and tear, improper cooling, or contamination of the mold.

● Dimensional inaccuracies can occur due to shrinkage during the cooling process, leading to out-of-tolerance dimensions.

In addition, the quality of the mold material, design, and maintenance can also affect the final product. A well-designed mold made from high-quality materials and properly maintained can produce consistent, high-quality wheels with minimal defects.

The quality of the LPDC wheel mold is determined by several factors, including the design, materials used, and manufacturing process.

The design of the mold must be precise, ensuring that the final product has the desired shape and size.

The materials used to manufacture the mold must be of high quality, as any defects or imperfections in the mold material can result in defects in the final product.

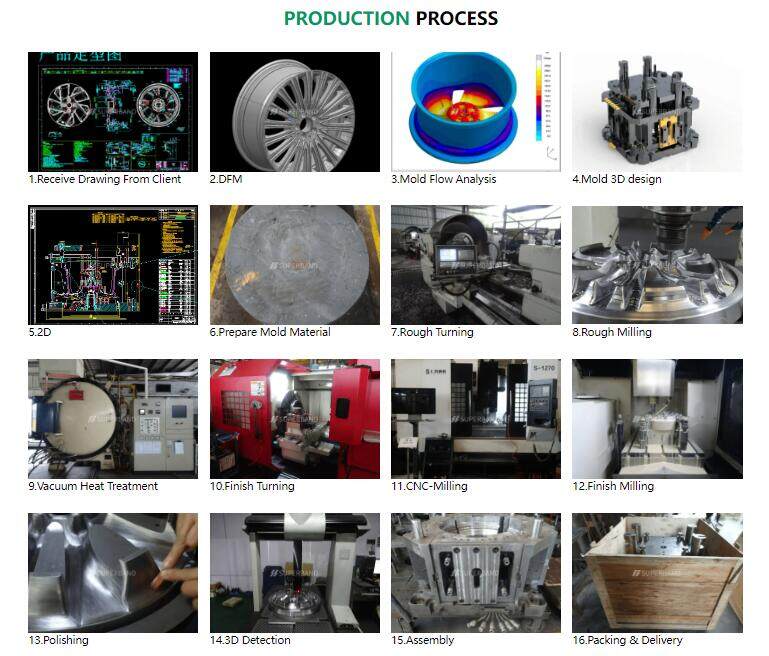

The LPDC wheel mold manufacturing process involves several steps, including design, fabrication, heat treatment, and finishing.

The design process typically involves the use of computer-aided design (CAD) software to create a precise model of the mold's shape and size.

The fabrication process involves the cutting, shaping, and assembly of the mold components, which are then subjected to heat treatment to increase their hardness and strength.

Finally, the mold undergoes finishing processes, such as polishing and coating, to ensure a smooth surface finish and protect against corrosion.

Therefore, the manufacturing process used to produce the molds must be precise to ensure that the molds are free of defects and flaws in order to obtain wheels of superior quality and longevity.

A high-quality mold will produce wheels that are free of defects, such as air pockets, porosity, and other imperfections that can affect the wheel's strength and durability.

Additionally, a high-quality mold will result in wheels that have a consistent shape and size, ensuring that they fit properly on the vehicle.

Maintaining the quality of the LPDC wheel mold is essential to ensure consistent production of high-quality wheels.

Regular maintenance and cleaning of the mold can help prevent defects and ensure proper functioning.

Additionally, inspections and testing of the mold's components, such as the cooling channels and ejector pins, can help identify any issues before they result in defects in the final product.

Overall, the quality of the LPDC wheel mold is critical to the final product's performance, appearance, and durability. By selecting high-quality materials and employing precise manufacturing processes, manufacturers can ensure consistent production of high-quality aluminum wheels that meet their customers' specifications.

Choosing a reliable wheel tooling manufacturer can help you get a quality LPDC wheel mold. When you are looking for LPDC wheel molds, Superband is the company that can help you. In either case, for selection or maintenance guidance, you are welcome to contact us to help you with the decision-making process.