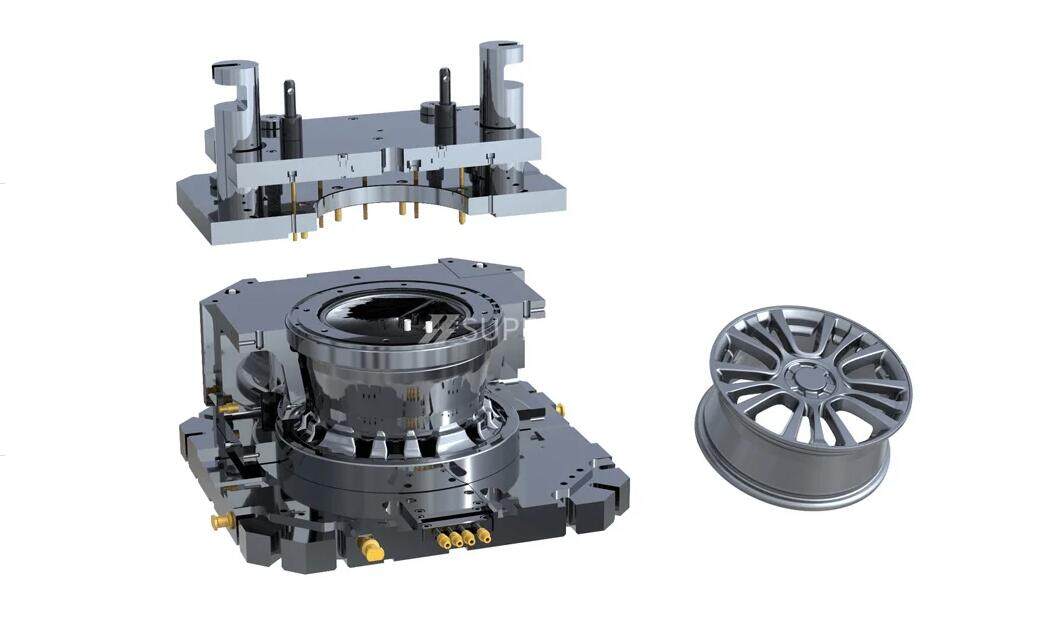

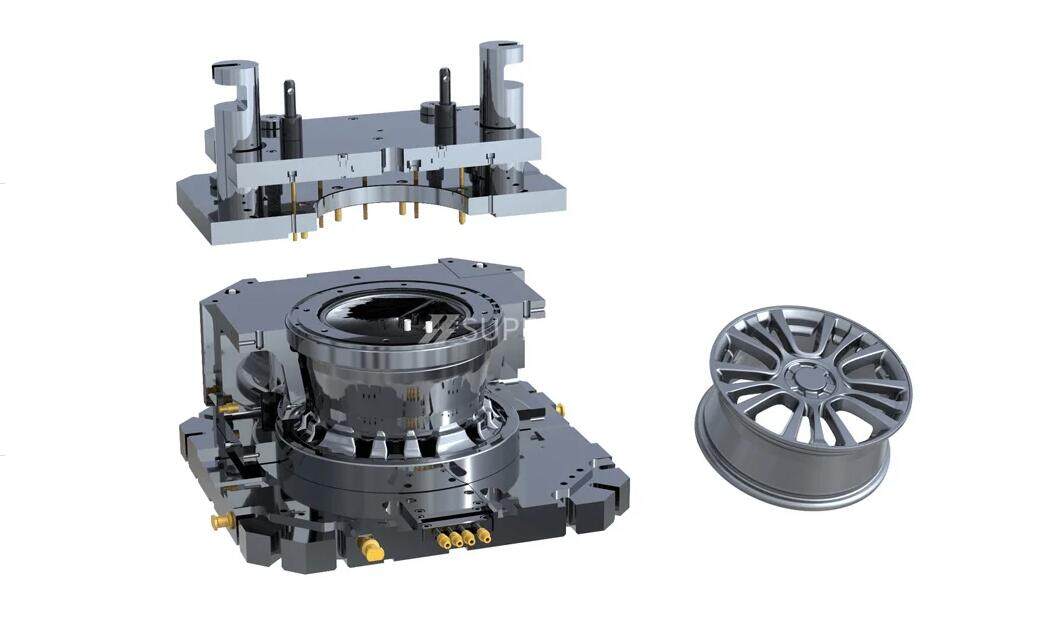

Low-Pressure Die Casting (LPDC) is a widely used manufacturing process for creating high-quality wheels for various applications. However, one question that many people have is, "How long does an LPDC wheel mold typically last?" Here we will discuss the lifespan of an LPDC wheel mold and the factors that can affect its longevity.

The Lifespan of an LPDC Wheel Mold

An LPDC wheel mold typically lasts for several thousand shots before it needs to be replaced. The exact lifespan of a mold will depend on several factors, such as the type of metal being cast, the design of the mold, and the maintenance and care of the mold. According to VEM Tooling, the lifespan of a mold can vary greatly, from a few hundred to over a million shots, depending on these factors.

Factors Affecting the Service Life of LPDC Wheel Molds

● The Type of Metal Being Cast

Some metals, such as aluminum and magnesium, have a higher thermal conductivity and are more abrasive, which can cause faster wear and tear on the mold. Other metals, such as steel, have lower thermal conductivity and are less abrasive, which can result in a longer lifespan for the mold.

● Mold Design

A well-designed mold will have a uniform wall thickness and a smooth surface finish, which can help reduce the stress and wear on the mold. A poorly designed mold, on the other hand, may have uneven wall thickness and rough surface finish, which can cause the mold to wear out more quickly.

● Maintenance and Care

Regular maintenance, such as cleaning and lubrication, can help prevent corrosion and extend the life of the mold. Proper handling and storage of the mold can also help reduce the risk of damage or deformation.

● The Production Volume and the Frequency of Mold Changes

In addition to these factors, the production volume and the frequency of mold changes can also affect the lifespan of an LPDC wheel mold. A high production volume and frequent mold changes can result in faster wear and tear on the mold, while a low production volume and infrequent mold changes can help extend the life of the mold.

Taking the Right Steps Will Prolong LPDC Life as Much as Possible

It is essential to note that the lifespan of an LPDC wheel mold is not fixed and can vary significantly depending on the above factors. Therefore, it is crucial to monitor the condition of the mold regularly and replace it when necessary to ensure consistent quality and production efficiency.

How Can I Extend the Lifespan of My LPDC Wheel Mold?

Proper maintenance and care are critical to extending the lifespan of an LPDC wheel mold. Regular maintenance, careful handling and storage, and proper design and selection of materials can all help extend the life of the mold and reduce the risk of premature failure. Working with a reputable manufacturer and following their recommendations for use and maintenance can also help to ensure the longevity of the mold.

In addition to extending the life of the mold, taking these steps can also help improve the quality of the final product and reduce the risk of defects or errors. A well-maintained mold will produce high-quality wheels consistently, resulting in increased customer satisfaction and repeat business.

How Often Should LPDC Wheel Molds Be Replaced?

The frequency of mold changes depends on several factors, including the production volume, the casting process, and the design and quality of the mold. Some molds may need to be replaced after only a few thousand casts, while others can last for hundreds of thousands or even millions of casts.

Can LPDC Wheel Molds Be Repaired If They Become Damaged?

LPDC wheel molds can often be repaired if they become damaged or worn. The repair process may involve welding, machining, or other methods, depending on the extent and type of damage.

Conclusion

The lifespan of an LPDC wheel mold can vary significantly depending on several factors, including the type of metal being cast, the design of the mold, and the maintenance and care of the mold. Regular maintenance, careful handling and storage, and proper design and selection of materials can all help extend the life of the mold and reduce the risk of premature failure. By taking these steps, businesses can improve the quality of their final product, reduce the risk of defects or errors, and ultimately increase customer satisfaction and repeat business.