Views: 0 Author: Site Editor Publish Time: 2025-05-22 Origin: Site

Have you ever wondered how metal parts get their exact shapes?The secret lies in a powerful tool called a die.Used in cars, electronics, and more, dies help shape and cut materials with precision.In this post, you’ll learn what the die process in manufacturing is and why it matters.

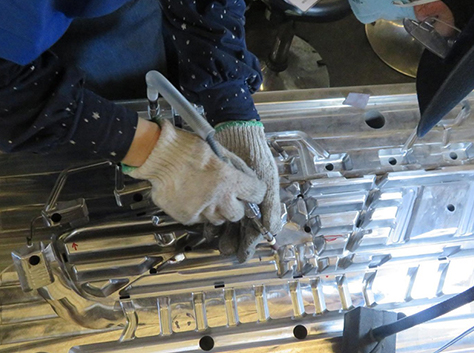

A die is a special tool. It helps shape or cut materials into precise forms. You’ll often find them in factories where metal parts are made.

Dies are used to form, bend, cut, or press materials—mostly metal. They work fast and repeat the same shape perfectly. Want a thousand metal brackets? A die can do that.It works by pressing material into a shaped cavity. That cavity gives the part its final shape.Here’s what dies can do:

Cut holes or shapes out of metal

Bend sheets into angles or curves

Punch, emboss, or stretch metal into 3D forms

People often mix up dies and molds. They’re similar, but not the same.

| Feature | Die | Mold |

|---|---|---|

| Material State | Solid (metal, mostly) | Liquid or molten (plastic, rubber) |

| Process Type | Stamping, cutting, bending | Pouring and hardening |

| Main Use | Metal forming | Plastic forming |

| Pressure Used | High-pressure stamping | Low to medium-pressure pouring |

So, if you’re pressing metal into a shape, you’re using a die. If you’re pouring plastic into a cavity, that’s a mold.

Most dies work with metal—steel, aluminum, copper, and more. But they can also form plastics, ceramics, and paper in some cases.The material has to be strong enough to be pressed. But also flexible enough to change shape under force.Common materials used with dies:

Sheet metal

Foils and thin strips

Pre-cut blanks

Dies don’t work alone. They need a stamping press to push them.The press brings two die halves together—top and bottom. The material sits between them. When the press closes, the die shapes the material.Some presses move up and down. Others use hydraulic pressure or motors. But all of them drive the die with force.This setup is used for:

Fast, repeatable production

High-volume part making

Complex shaping in one press stroke

You use things made with dies every day. Look around you.Here are just a few examples:

Car doors and frames

Electrical outlet covers

Soda can tops

Kitchen sink cut-outs

Phone casing brackets

These parts start as flat sheets. Then a die cuts or forms them into their final shape.Without dies, most metal products would take much longer—and cost more—to make.

A die set is like a machine's skeleton. Every part works together to shape or cut materials. If one piece is off, the whole system can fail. Let’s look at what’s inside—and why each part matters.

These are the base plates. Everything attaches to them. The upper shoe moves during each press stroke. The lower shoe stays fixed. They need to be super strong so they don't flex. Most are made of steel or cast iron.

This pair keeps things aligned. One side gets the guide pins, and the other gets bushings. The pins slide into the bushings to make sure both die halves meet in the right place—every time.Imagine two puzzle pieces locking together. That’s how they work.

The punch is like a shaped hammer. It moves down and hits the material. The cavity, its match, is the hollow part that receives the hit. Together, they form or cut the metal.

| Part | Description |

|---|---|

| Punch | The moving shape that cuts/forms |

| Cavity | The shaped space that holds it |

They take the most impact, so they’re made from tough tool steel.

After the punch hits, the material might stick. That’s where the stripper pad steps in. It pushes the part off as the punch moves up. Most use springs, but some are solid. No sticking means no slowdowns.

Things don’t always go perfectly. A crash in the press can destroy tools. Stop blocks limit how far the die closes. They protect the die from major damage. Some even help during setup using a built-in slot.

Before the press starts, the material needs to be in the right place. Pilots drop into small holes to line things up. Gauges make sure the strip or blank sits where it should. That way, every part comes out just like the last.

Springs are everywhere in a die. They push parts up. They hold things down. They help strip metal off punches. You’ll find different types: coil springs, nitrogen springs, and neoprene pads.

Each does a job based on how much force it needs to give or take.

Every component must fit together with extreme precision. If they’re even a little off, the die might jam, break, or ruin the part. That’s why die makers check and recheck during assembly. Precision isn’t optional—it’s the rule.

Not all dies are built the same. Some handle one simple task. Others perform a series of complex operations. The type of die you use depends on what kind of part you’re making—and how fast you need to make it.

This is the most basic type. It performs just one action per press stroke. For example, it might only punch a hole or cut out a shape. It’s best for parts that don’t need much shaping.

A compound die can do more. It performs multiple cutting actions in one stroke. That means it can pierce and blank at the same time. The part doesn’t move between steps—it all happens in one spot.This setup saves time. And it reduces errors since the part doesn’t shift.

Progressive dies are fast and efficient. They perform several steps across multiple stations in one die set. Each time the press comes down, the strip moves forward (we call this the pitch). At every station, something new happens to the part.

| Station | Operation |

|---|---|

| 1 | Piercing holes |

| 2 | Drawing shape |

| 3 | Idle (no action) |

| 4 | Flanging edges |

| 5 | Final cut-off |

The part stays connected to the strip until the last station. A coil feed system controls the movement—no extra equipment needed. It’s great for making small to medium parts in high volume.

Transfer dies work differently. Each operation happens in a separate die set. A part is cut from the strip early on. Then it moves between stations using transfer arms or robots.

Blank the part

Draw the shape

Trim and pierce

Flange or form edges

These dies can handle larger and more complex shapes. But they need extra equipment—like mechanical arms or servo transfer systems—to move the part.

This type of die makes several identical parts in one press stroke. Think of it like cookie cutters, all punching at once.Each cavity must be perfectly aligned and synced. That’s where synchronization mechanisms come in. If even one station is off, the whole system can jam or break.

Making multiple washers or brackets in one hit

Saving time during high-volume runs

Making a die takes more than just metal and machines. It’s a detailed process. Each step matters—because even a tiny error can ruin the final part. Here’s how it works from start to finish.

Before cutting anything, we start with the part design. Customers share what they need—size, shape, and performance. We talk through the details, from metal type to yearly production volume.

Then engineers use CAD software to create a digital model of the die. They simulate how metal will flow inside it using tools like FEA (Finite Element Analysis). This helps spot issues before making anything physical.

Important things to plan for:

Press tonnage needed

Thickness and type of material

How many cycles the die must survive

Once the design is ready, it's time to pick the right materials. Tool steel is common, but sometimes we use carbide or bronze for specific parts.We cut the raw material to size and may heat treat it. Heat treatment makes the metal hard enough to handle stress. It must also match any future coating requirements, like PVD or nitriding.

Material options often include:

D2 or A2 tool steel

Carbide inserts for wear areas

Impregnated bronze for bushings

Now we bring the design to life. CNC machines cut the basic shape. EDM (Electrical Discharge Machining) carves out sharp corners or tight features. Surface grinders smooth flat areas.Other steps like threading screw holes or sizing dowels happen here too. Sometimes, we leave a little extra material for final grinding or polishing.Common machining tools:

CNC mills for blocks

Wire EDM for fine details

Jig grinders for tight tolerance areas

After machining, it’s time to put the pieces together. We line up every pin, block, and plate exactly. A dry run happens first—no metal, just movement. We use cranes or hydraulics to open and close the die slowly.Then comes the real test. We install the die into a press and run a few sample parts. If something’s off—like a misaligned punch—we fix it here.Checklist during testing:

Does the part meet specs?

Are shapes clean and consistent?

Any signs of binding or collision?

If everything checks out, we polish key surfaces. A smoother surface helps parts eject better and reduces wear. We might add coatings like PVD for longer tool life.Finally, we inspect the whole die. Non-destructive testing like ultrasonic scans can check for hidden cracks. All specs, materials, and test results go into the final report.Quality checks often include:

Dimensional accuracy

Surface finish

Material hardness

Structural integrity

Die manufacturing and molding both shape materials—but they do it in totally different ways. It’s all about how the material starts and how it’s formed.

Dies shape solid materials, usually metal. The process uses pressure to cut, bend, or form metal sheets or blanks. No melting. No pouring. Just force.Molding, on the other hand, deals with liquids. Plastics, rubber, or molten metal are poured into a mold cavity. They cool and harden into the final shape.

| Process | Material State | Action |

|---|---|---|

| Die Manufacturing | Solid | Press and shape |

| Molding | Liquid | Pour and solidify |

Die tools are often more expensive up front. They’re built to handle high pressure and thousands of cycles. But for metal parts in huge volumes, dies save time and money in the long run.Molds can be less costly for small runs—especially for plastic items. They’re great when you need complex shapes and smooth finishes.

When to use each:

Die: Best for strong, flat, or formed metal parts

Mold: Ideal for plastic or rubber items with complex geometry

Car body panels

Soda can lids

Electrical brackets

Tool parts

Plastic bottles

Phone cases

Toy parts

Rubber seals

Die manufacturing is about stamping precision. Molding is about flowing material into shape. They serve different goals—but both are essential in manufacturing.

Making a die takes more than skill—it takes serious machines. Each tool has its job. Some cut. Others measure. Together, they bring the design to life.

Here’s a closer look at the key equipment.

This is the workhorse. It shapes blocks of steel into precise die components. It follows digital plans. Fast, repeatable, and perfect for cutting square, flat surfaces or deep cavities.

EDM stands for Electrical Discharge Machining. It uses sparks to cut metal—without touching it.

Wire EDM slices through metal using a thin wire.

Sinker EDM creates complex shapes in hard-to-reach areas.

These are great for tight corners and delicate details.

Need a perfectly flat surface? Use a surface grinder. It smooths die parts down to a fine finish. Essential for parts that must fit together without gaps.

This machine is all about precision. It fine-tunes holes, slots, or curves where even a tiny error matters. It’s slower—but super accurate.

Sometimes, a simple drill does the trick. Drill presses make straight, clean holes for bolts, screws, or alignment pins. Every die needs those.

Before cutting metal, you build the die on screen. CAD (Computer-Aided Design) tools let you draw it out. CAM (Computer-Aided Manufacturing) sends those instructions to the machines.

They help prevent mistakes before any material is touched.

After making parts, we need to check them. CMMs measure every detail. They compare real parts to the digital model. If something’s off—even by a hair—it gets fixed.

| Tool | What It Does |

|---|---|

| CNC Mill | Shapes steel with high precision |

| Wire/Sinker EDM | Cuts intricate forms without contact |

| Surface Grinder | Flattens and finishes surfaces |

| Jig Grinder | Refines holes and tight tolerances |

| Drill Press | Creates straight, round holes |

| CAD/CAM Software | Plans and controls machining |

| CMM | Inspects parts for exact dimensions |

Choosing the right material makes or breaks a die. It has to handle pressure, resist wear, and hold shape for thousands of cycles. Here’s what die makers usually work with—and why it matters.

Punches and cavities take the biggest hit. They need strength and hardness. Tool steels like D2 or A2 are the go-to. These metals resist wear and keep sharp edges, even under constant pressure.

If the punch gets dull or breaks, the whole die stops. That’s why this choice is so important.

Not every part in the die needs to be rock hard. Guide pins are made of hardened steel. But bushings? They’re usually made from softer materials—like bronze.

Why? It’s better to let the bushing wear out than the pin. Bronze bushings are easier and cheaper to replace.

| Part | Common Material | Reason |

|---|---|---|

| Guide Pin | Hardened Steel | Needs durability |

| Bushing | Bronze (impregnated) | Sacrificial wear surface |

Some jobs are just brutal—like stamping abrasive materials or high-volume runs. For those, carbide is a smart pick. It’s harder than tool steel and lasts longer.

We also use coatings like:

PVD (Physical Vapor Deposition)

Nitriding

These create a super-hard surface without changing the die’s core material.

Most die parts start as square blocks of metal. These blocks must be flat and true. Even a slight warp can throw off the whole die.Sometimes we order pre-squared material. Other times, we square it on a CNC machine. Either way, precision comes first. If the base is off, everything built on it will be too.

Die manufacturing powers nearly everything we touch—from cars to phones. It shapes the metal parts we rely on every day. Below are some key industries where dies play a huge role.

Cars use a lot of stamped metal. Dies form and cut body panels, support brackets, and internal reinforcements. Large transfer dies often shape parts like:

Door frames

Engine covers

Roof panels

Seat brackets

They need strength, precision, and speed—and dies deliver all three.

Think about your fridge, microwave, or laptop. Many parts inside them start from flat sheet metal. Dies punch, bend, or form those sheets into useful components.

Common examples:

Control panel frames

Mounting plates

Speaker enclosures

Laptop hinge brackets

These parts need to be light and fit perfectly. Dies make sure each one matches the design.

Medical tools must be precise—and clean. Dies are used to shape stainless steel parts for devices, trays, and cases.

You might find die-formed parts in:

Surgical equipment housings

Medical carts

Diagnostic machine shells

They’re made to tight tolerances and smooth finishes, which help with hygiene and safety.

Planes use complex metal parts that need to be strong but light. Dies help create parts from aluminum and titanium alloys.

Applications include:

Wing ribs

Bracing structures

Avionics mounts

Access panel frames

Aerospace dies must handle tough materials and hold exact shapes under high pressure.

Building a die is only the beginning. To keep production running smoothly, companies need support services too—like repair, maintenance, and training. These extras make a big difference.

Dies go through a lot. After thousands of press cycles, they can wear down or fail. Regular maintenance keeps them sharp and accurate. Quick repairs prevent downtime and expensive delays.

Companies like Berkness offer these services. They inspect, repair, and restore tools to their original specs. Some even upgrade tools with better coatings or redesigned parts for longer life.

Why it matters:

Extends tool lifespan

Keeps part quality consistent

Reduces emergency stoppages

Building and fixing dies takes experience. But today, many shops struggle to find skilled workers. That’s why training programs are so important.Companys like Superband help. They teach die design, troubleshooting, and shop safety. Their programs focus on hands-on learning and real-world situations.

Training helps with:

Growing the next generation of toolmakers

Improving efficiency and safety

Reducing errors on the shop floor

Understanding the die process helps lower costs and boost product quality. It also helps teams pick the right die type.Knowing this process makes it easier to work with toolmakers and suppliers. Everyone stays on the same page.Dies require precision, planning, and the right equipment. They're key to shaping the world around us.If you're unsure what die fits your needs, talk to a specialist. They’ll guide you toward a smart, efficient solution.

A: Common types include simple, compound, progressive, transfer, and multiple dies. Each serves different production needs.

A: Dies are cleaned, inspected, and repaired regularly to prevent wear, avoid failure, and maintain part quality.

A: Lifespan depends on material, coating, and use. With proper care, some dies can last hundreds of thousands of cycles.

A: Usually no. Dies are custom-made for specific shapes, but some may be modified for similar designs.

A: Costs vary widely based on size, complexity, and materials—ranging from a few thousand to hundreds of thousands.