Views: 0 Author: Site Editor Publish Time: 2025-06-03 Origin: Site

How are detailed aluminum parts made so fast and precise?High-Pressure Die Casting (HPDC) could be the key.In this post, you’ll learn what HPDC is, how it works, and why it's used across many industries.

HPDC stands for High-Pressure Die Casting.It’s a manufacturing process where molten aluminum is injected into a steel mold at extremely high pressure.This creates precise, detailed metal parts in just seconds.HPDC is one of the most popular aluminum die casting methods today.It belongs to the pressure die casting family, alongside low-pressure and vacuum die casting.What sets HPDC apart is its speed and ability to make complex shapes with tight tolerances.

HPDC starts with molten aluminum. It’s forced into a hardened steel die using hydraulic pressure—often over 1,000 bar.

The metal fills the mold quickly. Then it solidifies while still under pressure.

This high-pressure fill prevents air pockets and ensures a smooth, dense structure.

Once cooled, the part is ejected from the mold automatically.

The steel mold can be used again and again—often thousands of times.

This makes HPDC ideal for high-volume production.

| Key Feature | Benefit |

|---|---|

| High pressure | Sharp details, smooth finish |

| Fast solidification | Shorter cycle times |

| Reusable steel molds | Lower cost per part in long runs |

| Automated ejection | High-speed, efficient production |

Before casting begins, the mold must be ready.

Operators apply die release agents to prevent metal from sticking.

Then they preheat the dies to around 180–250°C. This reduces thermal shock and improves part quality.

Proper prep means smoother flow and fewer defects.

Here’s where the action happens fast.

Molten aluminum, at about 660°C, is injected into the die cavity.

Pressure often exceeds 1000 bar. The metal fills the cavity in just milliseconds.

Speed ensures thin walls and sharp detail.

| Parameter | Typical Value |

|---|---|

| Pressure | 1000–2000 bar |

| Injection Time | < 100 milliseconds |

| Melt Temp | ~660°C |

As soon as the cavity fills, cooling begins.

High thermal conductivity of the steel mold draws heat rapidly.

This leads to solidification in 30–60 seconds, depending on part size and design.

Cooling channels inside the die help regulate temperature.

Quick cooling = faster cycles + better strength.

Once solid, the part is ejected automatically using ejector pins.

The casting leaves the die, but it isn’t finished yet.

Operators trim off gates, runners, and any flash—extra metal that seeped between die halves.

Parts may also go through deflashing or grinding for a smooth finish.

| Step | Action Taken |

|---|---|

| Ejection | Ejector pins push part out of die |

| Trimming | Cut off runners, gates, and flash |

| Finishing | Optional polishing or machining |

HPDC is known for its speed and precision. Parts are formed in seconds and need minimal finishing.It delivers excellent dimensional accuracy, even for thin-walled or complex shapes.The surface finish is smooth and consistent, ideal for visible or tight-tolerance parts.You can produce thousands of castings quickly. That makes HPDC perfect for high-volume manufacturing.It also offers high repeatability. Each part looks and functions just like the last.Scrap rates stay low because defects are minimized with controlled injection and fast solidification.

| Benefit | What It Means |

|---|---|

| High Accuracy | Tight tolerances and complex shapes |

| Smooth Surface Finish | Less machining and better aesthetics |

| Fast Cycle Times | 30–60 seconds per part |

| Repeatability | Reliable for mass production |

| Low Scrap Rate | Fewer defects, less material waste |

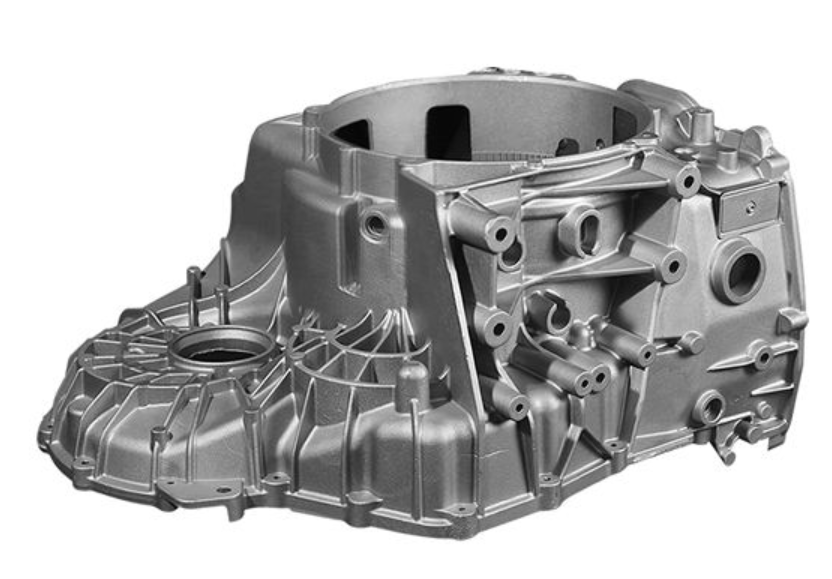

HPDC isn’t just fast—it’s widely used across many industries.In automotive, it forms parts like engine blocks, transmission housings, and suspension components.Consumer electronics benefit from thin, strong aluminum frames for phones, laptops, and heatsinks.Industrial machinery often uses HPDC to make precise housings, pump bodies, and structural parts.The lighting industry relies on HPDC for aluminum housings, brackets, and thermal components.

| Industry | Example HPDC Parts |

|---|---|

| Automotive | Engine blocks, gearboxes, brackets |

| Consumer Electronics | Laptop frames, heatsinks, device housings |

| Industrial Equipment | Pump bodies, gear cases, enclosures |

| Lighting | Fixture housings, heat sinks, mounts |

HPDC uses extremely high pressure—over 1000 bar—to inject molten aluminum fast.

LPDC works differently. It uses low pressure, around 0.5–1.5 bar, to fill the mold slowly from below.

HPDC is faster, making it perfect for high-volume production where speed and accuracy matter.

LPDC is better for larger castings or thicker walls where slower filling avoids air entrapment.

HPDC shines in electronics and automotive. LPDC fits well in wheels, structural parts, and large housings.

Gravity casting doesn’t use pressure. Molten metal flows into the mold by gravity alone.

That limits speed and part complexity. You can’t get ultra-thin walls or fine details.

HPDC forces metal into tight spaces. It makes complex shapes with excellent precision and smooth surfaces.

Use gravity casting when cost is key and shape is simple. Use HPDC for sharp detail and thin walls.

| Feature | HPDC | LPDC | Gravity Casting |

|---|---|---|---|

| Pressure | High (1000+ bar) | Low (0.5–1.5 bar) | None |

| Speed | Very fast | Moderate | Slow |

| Wall Thickness | Thinner possible | Medium | Thick |

| Surface Finish | Very smooth | Good | Average |

| Applications | Detailed, mass production | Large, structural parts | Simple, low-volume parts |

HPDC works best with specific aluminum alloys. These alloys combine strength, flow, and surface quality.

ADC12 is widely used in Asia. It offers excellent castability and corrosion resistance. It’s perfect for complex parts.

A380 is a top choice in North America. It balances strength, thermal conductivity, and wear resistance.

AlSi9Cu3 is popular in Europe. It delivers great pressure tightness and low porosity—ideal for sealing applications.

| Alloy | Region | Key Benefits | Best Used For |

|---|---|---|---|

| ADC12 | Asia | Great flow, corrosion resistance, machinability | Consumer electronics, housings |

| A380 | North America | Strong, stable, heat resistant | Automotive, industrial components |

| AlSi9Cu3 | Europe | Low porosity, high sealing performance | Pumps, pressure-tight parts |

Choosing the right alloy depends on your part’s function and the production environment.

If your part needs strength under pressure, pick A380. It holds shape well and resists heat.

For parts exposed to moisture, choose ADC12 for its corrosion resistance and ease of finishing.

Use AlSi9Cu3 when pressure sealing matters. It reduces gas porosity and is easy to weld or braze.

Also factor in cost and tool wear. Some alloys run cooler and reduce die damage over time.

Ask: “What’s more important—price, strength, or corrosion resistance?” That’s how you decide.

HPDC dies face extreme heat and pressure—every cycle, every shot.That’s why most are made from H13 tool steel. It handles thermal shock, resists wear, and keeps its shape.H13 also holds up under rapid cooling and reheating, which happens constantly during casting.

| Property | H13 Tool Steel Benefit |

|---|---|

| High thermal stability | Prevents distortion under heat |

| Wear resistance | Longer die life, fewer defects |

| Toughness | Withstands high injection forces |

Efficient HPDC needs more than a strong die. It needs cooling balance.Dies include internal channels that circulate water or oil. This keeps temperatures stable, avoiding hot spots.Uneven cooling can cause shrinkage, porosity, or cracks. Good die design prevents that.Also, proper venting ensures trapped gases escape before the metal solidifies.

| Feature | Why It Matters |

|---|---|

| Cooling channels | Maintain cycle speed and quality |

| Thermal balance | Reduces internal stress |

| Gas vents | Prevents porosity and air traps |

Die life depends on part complexity, alloy type, and maintenance habits.A typical HPDC die can last 50,000 to 100,000 shots or more.But only with regular care. That means cleaning, re-coating surfaces, checking alignment, and monitoring thermal fatigue.Some shops inspect dies after every 5,000 to 10,000 cycles.

| Maintenance Task | Frequency Recommendation |

|---|---|

| Surface cleaning | After each production run |

| Die inspection | Every 5,000–10,000 shots |

| Thermal monitoring | Continuous during operation |

Controlling HPDC requires more than just turning on a machine. You need to monitor several vital settings.

Injection Pressure: Usually exceeds 1000 bar. High pressure ensures proper mold filling.

Melt Temperature: Should stay around 660–700°C for aluminum. Too low? Incomplete fill. Too high? Die damage risk.

Die Temperature: Balanced dies prevent thermal fatigue and cold shuts.

Shot Speed: Must be optimized. Too fast causes turbulence. Too slow leads to misruns.

| Parameter | Typical Range | Impact on Quality |

|---|---|---|

| Injection Pressure | 1000–1500 bar | Ensures full cavity fill |

| Melt Temp | 660–700°C | Prevents cold shuts and porosity |

| Die Temp | 180–250°C | Reduces stress, extends tool life |

| Shot Speed | 0.5–5 m/s | Affects turbulence and flow |

Even in a controlled process, defects can appear. Recognizing and correcting them early saves cost and time.

Porosity: Caused by trapped gas or shrinkage. Use vacuum systems, optimize gate design.

Cold Shuts: Incomplete fusion of metal fronts. Fix by increasing die or melt temperature.

Flash: Excess metal leaks at die parting lines. Caused by high pressure or worn tooling.

Incomplete Fill: Results from low shot speed, metal temperature, or venting issues.

| Defect | Cause | Solution |

|---|---|---|

| Porosity | Trapped gas, shrinkage | Vacuum casting, adjust gating |

| Cold Shuts | Low temp, slow flow | Increase melt and die temperature |

| Flash | Tool wear, high injection pressure | Rebuild tooling, adjust pressure |

| Incomplete Fill | Poor venting, low shot speed | Improve vents, boost shot speed |

After casting, quality isn’t just visual—it must be verified with precision.

X-Ray Inspection: Reveals internal voids or porosity.

CT Scanning: 3D imaging for complex parts. Ideal for structural analysis.

Leak Testing: Used for parts like housings or pump bodies. Ensures air or fluid tightness.

Dimensional Checks: Verifies tolerances using CMM or calipers.

| Test Method | What It Detects | Best For |

|---|---|---|

| X-Ray | Voids, shrinkage, cracks | Internal defects in dense areas |

| CT Scan | Full 3D structure | Thin walls, complex geometry |

| Leak Test | Seal integrity | Pressure-tight parts |

| Dimensional Check | Size and form accuracy | Tolerance-critical components |

HPDC shines when you're producing thousands—or millions—of parts.Its speed and consistency make it ideal for high-volume manufacturing.If you're running short batches, the tooling cost might not be worth it.

| Production Volume | HPDC Suitability |

|---|---|

| Under 1,000 units | Not cost-effective |

| 1,000–10,000 units | Possibly viable |

| 10,000+ units | Highly cost-efficient |

HPDC handles complex shapes and thin walls with ease.It works best when tolerances are tight and the finish needs to be smooth.Sharp corners, bosses, ribs, and undercuts are no problem—with proper die design.You can even combine parts into one casting to reduce assembly steps.Use it for designs that demand strength, detail, and speed.

Tooling for HPDC isn't cheap. Dies are made of steel and take time to produce.Expect higher upfront costs compared to other casting methods.However, if you're making lots of parts, you’ll save more over time.Each shot is fast—seconds, not minutes—so labor and cycle time costs drop quickly.

| Factor | HPDC Advantage |

|---|---|

| Tooling Cost | High, but long-lasting |

| Production Speed | Extremely fast (30–60 sec per cycle) |

| Total Cost per Unit | Low for large batches |

HPDC delivers fast, accurate, and repeatable aluminum casting results.It's best for complex shapes and large production runs.Before choosing, consider your design, volume, and cost goals.

A: It’s a fast, high-pressure method where molten aluminum fills a steel mold to form detailed parts.

A: HPDC is quicker, more precise, and ideal for making complex, high-volume aluminum components.

A: It's widely used in automotive, electronics, lighting, and industrial manufacturing.