2023-05-05

Aluminum alloy die-casting auto engine brackets are structural components used in the automotive industry to secure and support the engine. Engine brackets are typically made from aluminum alloy, a lightweight and strong material that is ideal for reducing weight and improving fuel efficiency in vehicles.

Auto engine brackets are critical components that play a key role in the proper functioning and performance of the vehicle. They help to secure the engine in place, absorb and dampen vibrations and shocks, and provide support for other engine components such as the alternator, power steering pump, and air conditioning compressor.

Aluminum alloy dies casting is a manufacturing process that involves injecting molten aluminum into a die or mold to create the desired shape of the engine bracket. The process is fast, cost-effective, and allows for the production of complex and intricate designs with high precision and accuracy.

Aluminum alloy die-casting auto engine brackets offer several advantages over other manufacturing processes such as stamping or forging. They are lightweight, strong, and durable, and can be produced in large quantities with high accuracy and consistency. Additionally, the die-casting process allows for the creation of complex and intricate designs that are not possible with other manufacturing methods.

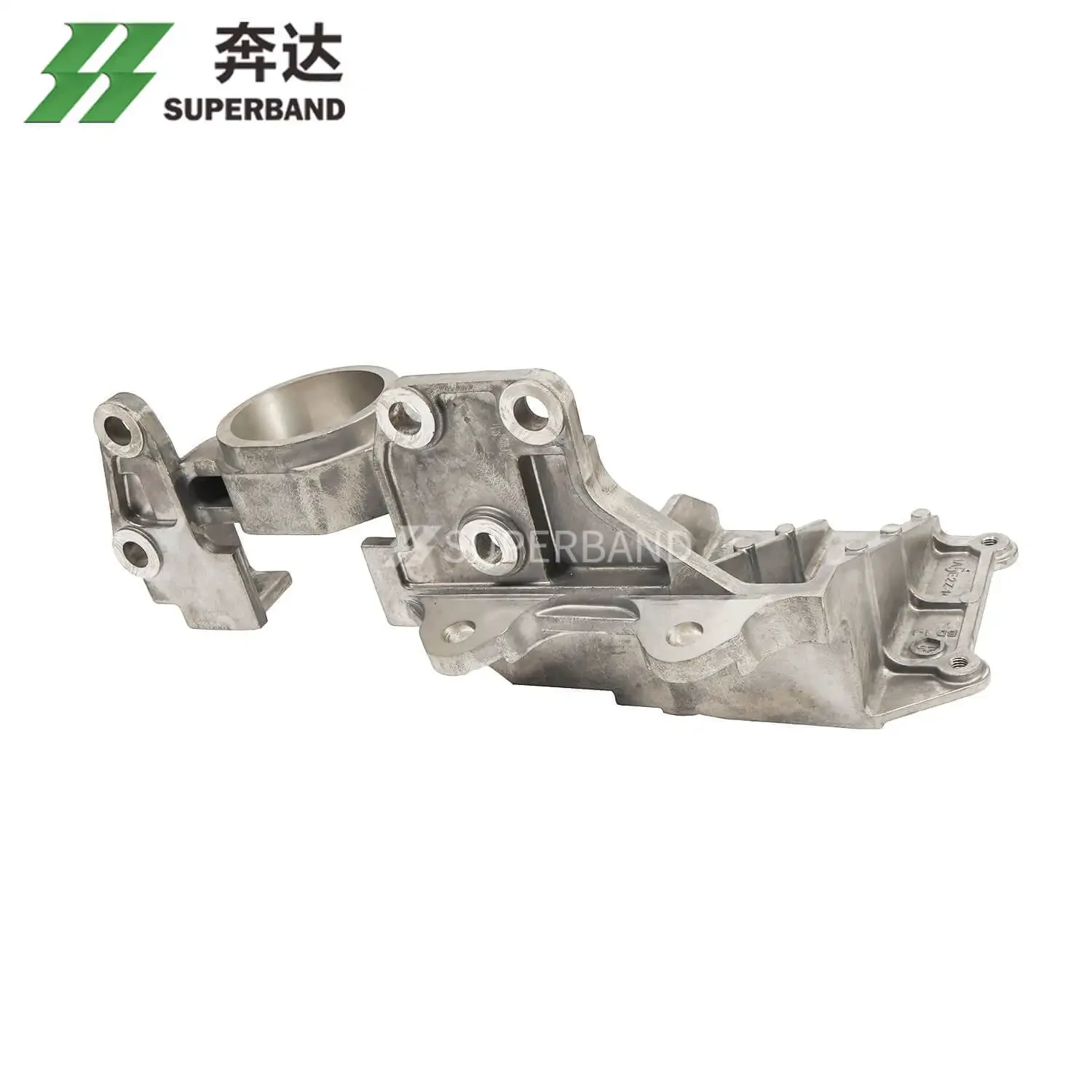

| Product Name | Aluminum Alloy Die Casting Auto Engine Brackets |

| Material | ADC12(Aluminum Alloy) |

| Specifacation | 208mm*196mm*92mm |

| Machine Application | 400T |

| Characteristics | High Tensile Strength / Large Wall Thickness / High Hardness Requirement |

| Casting Method | High Pressure Die Casting (Oxygenate Perssure Casting) |

| Processing Metod | CNC Machining |

| Package | Carton |

There are several benefits to using aluminum alloy die casting for auto engine brackets, including:

● Lightweight Design

● High Strength

● Corrosion Resistance

● Cost-Effective

The manufacturing process for aluminum alloy die-casting auto engine brackets involves mold creation, melting and pouring, and removal and finishing.

When considering using aluminum alloy die casting for auto engine brackets, manufacturers should keep the following factors in mind:

The design of the engine bracket will impact the manufacturing process and may increase the cost or time required for production.

The quality of the final product will depend on the quality of the mold and the casting process. Manufacturers should ensure that their molds are designed and machined to exact specifications and that the casting process is closely monitored for quality control.

The final appearance and surface finish of the engine bracket are critical for both aesthetic and functional reasons. Manufacturers should consider the finishing and surface treatment options available and choose the most appropriate option for their specific application.

Finishing and surface treatment of automotive engine brackets are important for several reasons:

The appearance of the engine bracket is important for the overall aesthetic appeal of the vehicle. A polished or coated surface can give the engine compartment a sleek and professional look.

Without proper surface treatment, aluminum can corrode, which can lead to structural damage and even failure of the engine bracket. Surface treatments like anodizing, chromate conversion coating, or powder coating can protect against corrosion and improve durability.

Some surface treatments can reduce friction, which can lead to improved performance and efficiency of the engine.

The engine bracket can generate a lot of heat, and proper surface treatment can improve heat dissipation, preventing damage to the engine or other components.

Aluminum alloy die casting can be used for a wide range of automotive components. In fact, aluminum is one of the most commonly used materials in the automotive industry.

Here are some examples of other automotive components that can be made using aluminum alloy die casting:

● Transmission housings

● Suspension components

● Brake calipers

● Intake manifolds

● Engine blocks

Overall, aluminum is a sustainable and recyclable material, making it an environmentally friendly choice for automotive components. Aluminum alloy dies casting is a popular choice for many automotive components due to its lightweight design, high strength, and cost-effectiveness.

As aluminum die casting mold suppliers of high efficiency and high-performance solutions for the aluminum alloy die casting industry, We support your product from initial concept through series production and execute entire lifecycle management for each aluminum die casting mold to respond to the client's demands.

We can supply many services to meet and exceed your expectations. Contact Superband to know more about automotive engine brackets, and aluminum alloy wheel engineering.