2023-05-05

Automotive steering knuckles play a critical role in the steering and suspension systems of a vehicle. These knuckles connect the wheel to the suspension and are responsible for transferring the steering motion to the wheel. To create high-quality steering knuckles, manufacturers rely on aluminum automotive steering knuckle molds.

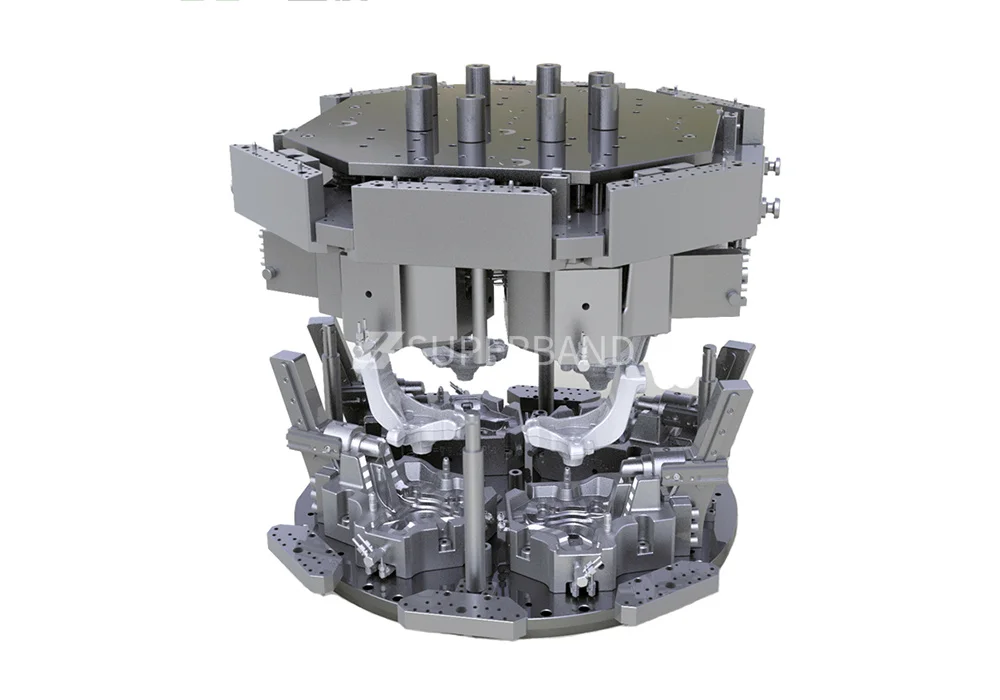

An aluminum automotive steering knuckle mold is a tool used in the manufacturing process of steering knuckles for automotive applications. It is designed to create a precise and durable mold of the steering knuckle, which is then used to produce multiple copies of the same part.

Aluminum automotive steering knuckle molds are used to produce steering knuckles for a wide range of vehicles, including cars, trucks, and buses. These steering knuckle molds are used to create steering knuckles that meet the specific requirements of each vehicle model, ensuring optimal performance and safety.

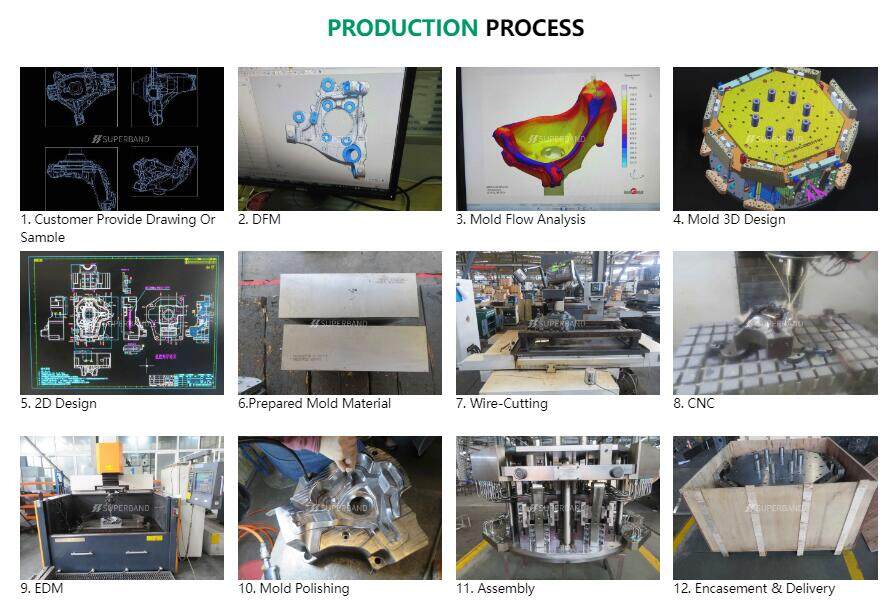

The manufacturing process for aluminum automotive steering knuckle molds involves several main steps, including:

● Design: The design of the mold is the first step in the manufacturing process. The mold is designed using computer-aided design (CAD) software, which allows for precise and accurate designs.

● Material Selection: The next step is selecting the appropriate aluminum alloy for the mold. The alloy selected will depend on the specific requirements of the steering knuckle being produced.

● Machining: Once the design and material selection is complete, the mold is machined using computer numerical control (CNC) machines. This process involves cutting, drilling, and milling the mold to the exact specifications required for the final product.

● Heat Treatment: After the machining process is complete, the mold undergoes a heat treatment process to improve its strength and durability.

● Finishing: The final step in the manufacturing process involves finishing the mold to ensure its smooth surface and precise dimensions. It is achieved through polishing, sandblasting, or other surface finishing techniques.

The lifespan of an aluminum automotive steering knuckle mold will depend on several factors, including the frequency of use, the complexity of the design, and the quality of maintenance and care. With proper care and maintenance, these molds can last for many years.

● Durability: Aluminum is a highly durable material that can withstand high temperatures and pressure, making it ideal for use in automotive molds.

● Precision: Aluminum automotive steering knuckle molds can produce high-precision parts that meet the exact specifications required for automotive applications.

● Cost-effectiveness: Compared to other materials, aluminum molds are cost-effective and can be manufactured in large quantities, making them ideal for mass production.

● Lightweight: Aluminum is a lightweight material that reduces the overall weight of the vehicle, leading to better fuel efficiency and improved handling.

As the automotive industry continues to evolve, the demand for high-quality steering knuckles will only increase. By utilizing aluminum automotive steering knuckle molds, manufacturers can meet this demand while maintaining efficiency and cost-effectiveness. These steering knuckle molds are a crucial component of the manufacturing process, and their importance cannot be overstated.