2023-02-28

LPDC (Low-Pressure Die Casting) is a widely used process for manufacturing high-quality wheels for various industries, including automotive, aerospace, and others.

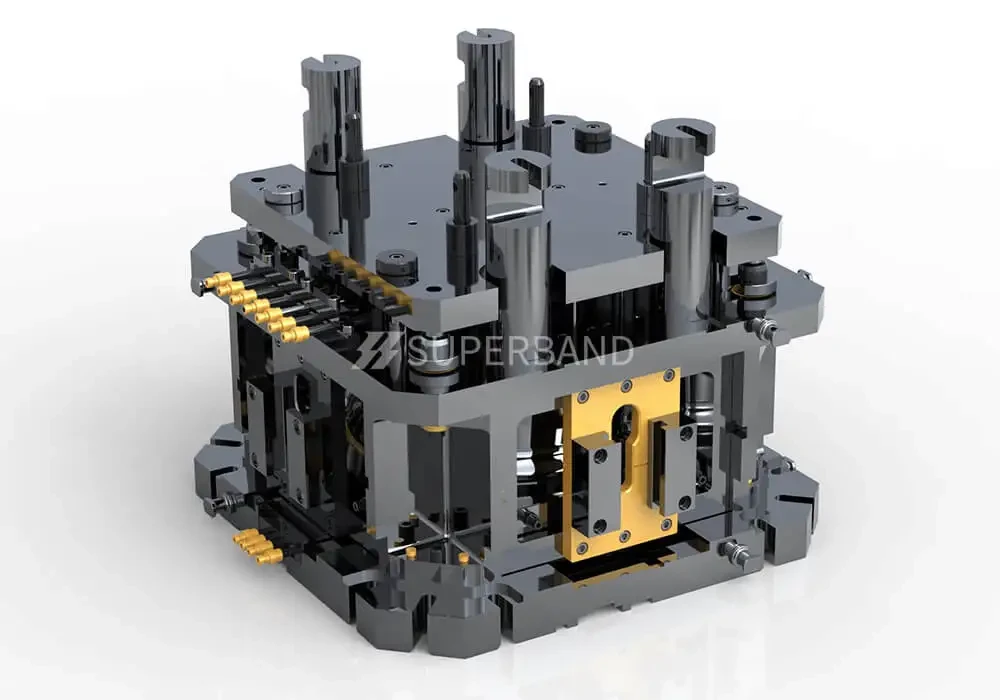

In the LPDC process, a mold tool is used to cast the wheel with molten metal at low pressure. This tool plays a crucial role in the success of the LPDC process. By exploring the advantages of using LPDC wheel mold tools, you may get more confirmation of the importance of LPDC wheel molds in the wheel manufacturing industry.

An LPDC wheel mold tool is a specialized tool used in the LPDC process for casting wheels with complex shapes and designs with molten metal at low pressure. A high level of quality and consistency can be achieved with the LPDC process when using a well-designed and maintained LPDC wheel mold tool.

An LPDC wheel mold works by evenly distributing the molten metal in the mold cavity, resulting in a consistent and uniform wheel structure.

LPDC wheel mold tools are typically made from high-quality materials, such as steel or aluminum, that can withstand the high temperatures and pressures of the casting process.

The LPDC process is known for producing high-quality wheels that meet the required specifications. The LPDC wheel mold tool plays a crucial role in achieving this level of quality.

It ensures the molten metal is evenly distributed in the mold cavity, resulting in a consistent and uniform wheel structure, and the result is a wheel that is durable, reliable, and aesthetically pleasing.

The LPDC process is a cost-effective way of producing high-quality wheels compared to other casting methods. The LPDC wheel mold tool is designed to minimize waste and maximize production efficiency, resulting in a lower cost per part. This cost-effectiveness is beneficial to manufacturers who are looking to reduce their production costs and increase profits.

LPDC wheel mold tools are highly versatile and can be used to produce wheels of different shapes, sizes, and designs.

The LPDC process can cast wheels with complex designs that would be difficult to achieve with other casting methods. This versatility makes the LPDC process an ideal choice for manufacturers who need customized wheels for specific applications.

The lifespan of an LPDC wheel mold depends on several factors, such as the material used, the frequency of use, and the maintenance practices. However, LPDC wheel mold tools are designed to last for several years with proper care and maintenance.

The design of an LPDC wheel mold tool is a critical factor in achieving a high level of quality in the LPDC process. The mold cavity must be precisely designed to ensure the molten metal is evenly distributed, resulting in a consistent and uniform wheel structure. The LPDC mold must also be designed to allow for easy removal of the cast wheel without causing any damage.

The quality of the LPDC wheel mold tool is also essential in achieving a high level of quality in the casting process. LPDC molds must also be well-maintained to ensure it remains in good condition and can continue to produce high-quality wheels for many years.

The LPDC wheel mold and process are used in various industries, including automotive, aerospace, and others, to produce high-quality wheels.

LPDC wheel mold is cost-effective and versatile, making it an ideal choice for manufacturers who need customized wheels with complex shapes and designs.

The LPDC wheel mold tool must be well-designed and maintained to ensure it remains in good condition and can continue to produce high-quality wheels for many years.