2023-05-02

Flow forming casting is a manufacturing technology that is rapidly gaining popularity in the wheel industry. This process involves spinning a wheel rim at high speeds while applying pressure to the inner barrel of the wheel. The result is a stronger, lighter, and more durable wheel than those produced through traditional casting methods.

Some of the benefits of using flow form casting in wheel manufacturing include the following:

Flow forming casting produces wheels with a more uniform grain structure, which results in a stronger and more durable wheel. The process also reduces the likelihood of cracks, fractures, and other types of damage, ensuring that the wheels can withstand the rigors of everyday driving, as well as high-performance and racing applications.

Flow forming mold design produces wheels that are lighter than those produced through traditional casting methods. This is because the process creates a denser, more uniform metal structure, which reduces the weight of the wheel without compromising its strength and durability. Lighter wheels result in better handling, improved fuel efficiency, and a smoother ride.

The strength, durability, and lighter weight of flow-formed wheels all contribute to better performance. These wheels offer improved handling, acceleration, and braking, which can make a significant difference in high-performance and racing applications. Additionally, the reduction in unsprung weight can improve the suspension's response, resulting in better ride quality and handling.

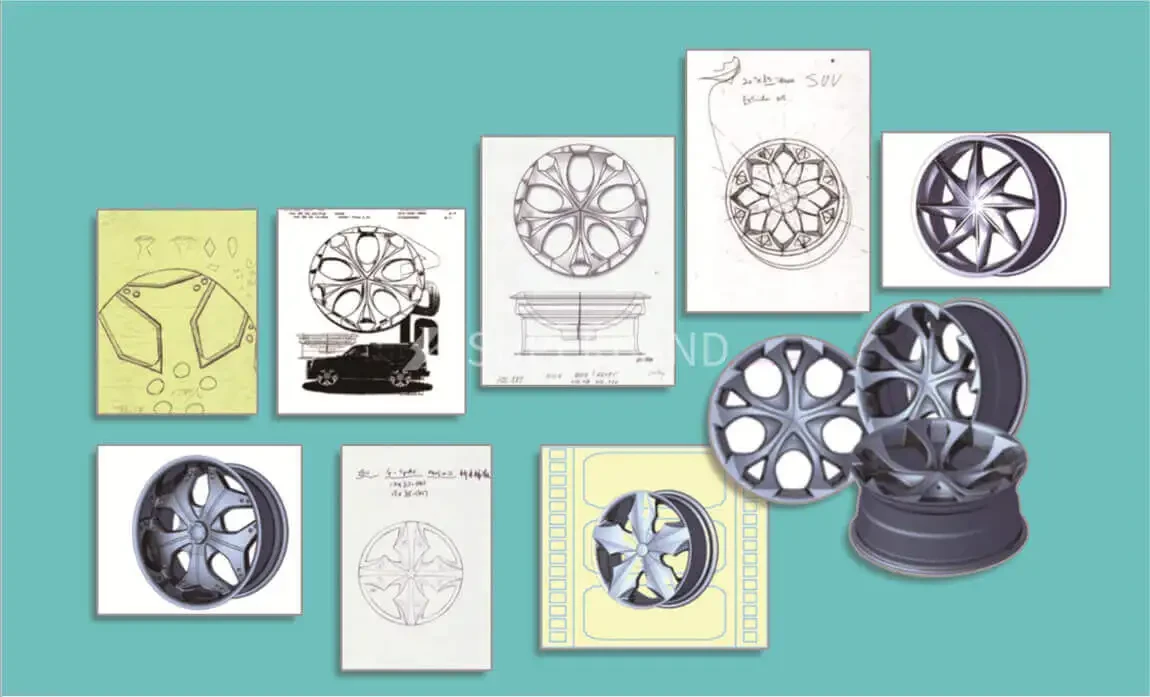

Flow forming casting allows for greater design flexibility than traditional casting methods. Manufacturers can create wheels with unique designs, finishes, and dimensions, allowing them to meet the demands of car enthusiasts and racing teams who are looking for wheels that stand out from the crowd. Additionally, the process can produce wheels with complex shapes and intricate details, which can be difficult or impossible to achieve through traditional casting methods.

While flow forming casting may be a more expensive process than traditional casting methods, it can be more cost-effective in the long run. The durability of flow-formed wheels means they are less likely to need to be replaced, resulting in long-term cost savings. Additionally, the process can produce wheels with greater precision and consistency, reducing the likelihood of costly errors and rework.

Flow forming casting is an environmentally friendly process, as it produces less waste than traditional casting methods. Additionally, the process uses less energy and produces fewer greenhouse gas emissions than other manufacturing technologies, making it a more sustainable option.

Flow forming casting produces wheels with a smoother surface finish than those produced through traditional casting methods. This can result in a more polished and refined look, as well as improved paint adhesion and resistance to corrosion.

Flow forming casting allows for greater customization options than traditional casting methods. Manufacturers can produce wheels in a variety of finishes, including polished, painted, and powder-coated. Additionally, they can create wheels in unique sizes and dimensions, allowing them to meet the demands of a wide range of customers.

Flow forming casting produces wheels with a higher strength-to-weight ratio than those produced through traditional casting methods. This means that the wheels are stronger and more durable while still being lightweight, resulting in improved performance and handling.

In conclusion, flow forming casting offers numerous benefits over traditional casting methods for wheel manufacturing. The process produces wheels that are stronger, lighter, and more durable, while also offering greater design flexibility, customization options, and cost-effectiveness.

As the wheel industry continues to evolve, it is likely that more manufacturers will turn to flow forming casting as their preferred manufacturing technology.