2024-04-02

Injection molding is a widely used manufacturing process for producing parts in large volumes. Among the various types of molds available for injection molding, aluminum molds stand out for several advantages they offer. From cost-effectiveness to improved cycle times, aluminum injection molds have become a preferred choice for many industries.

The following are the advantages of using aluminum injection molds:

Aluminum injection molds are generally more cost-effective to manufacture compared to steel molds. This is because aluminum is easier to machine and has a lower material cost. Lower manufacturing costs translate to reduced upfront expenses for companies, especially for smaller production runs or prototyping purposes. Additionally, aluminum molds can be modified or repaired more easily and at a lower cost compared to steel molds, saving both time and money over the mold's lifecycle.

Aluminum has excellent thermal conductivity properties, allowing for faster heat dissipation during the cooling phase of the injection molding process. Faster cooling times result in shorter cycle times, increasing overall production efficiency and reducing manufacturing costs. The ability to achieve rapid cooling also helps in minimizing warpage and improving the dimensional accuracy of molded parts.

Aluminum molds are significantly lighter than steel molds, making them easier to handle and manipulate during setup and operation. It is particularly advantageous for manual loading and unloading of molds, reducing the risk of injuries to operators and facilitating quicker changeovers between production runs.

Aluminum molds can be polished to a high degree of smoothness, resulting in superior surface finishes on molded parts. The smooth surface finish reduces the need for secondary finishing operations, such as polishing or painting, saving both time and resources in post-processing.

Aluminum molds offer better thermal control compared to other materials, allowing for more precise temperature regulation during the injection molding process. Consistent temperature control helps in achieving uniform part quality and reducing the likelihood of defects such as sink marks or surface blemishes.

Due to their superior thermal conductivity, aluminum molds require less energy to maintain optimal operating temperatures during the injection molding process. Lower energy consumption leads to reduced production costs and environmental impact, making aluminum molds a more sustainable choice for manufacturers.

Aluminum injection molds can be fabricated more quickly than steel molds due to the material's ease of machining. Shorter lead times enable manufacturers to respond more swiftly to changing market demands and shorten time-to-market for new products, giving them a competitive edge in the industry.

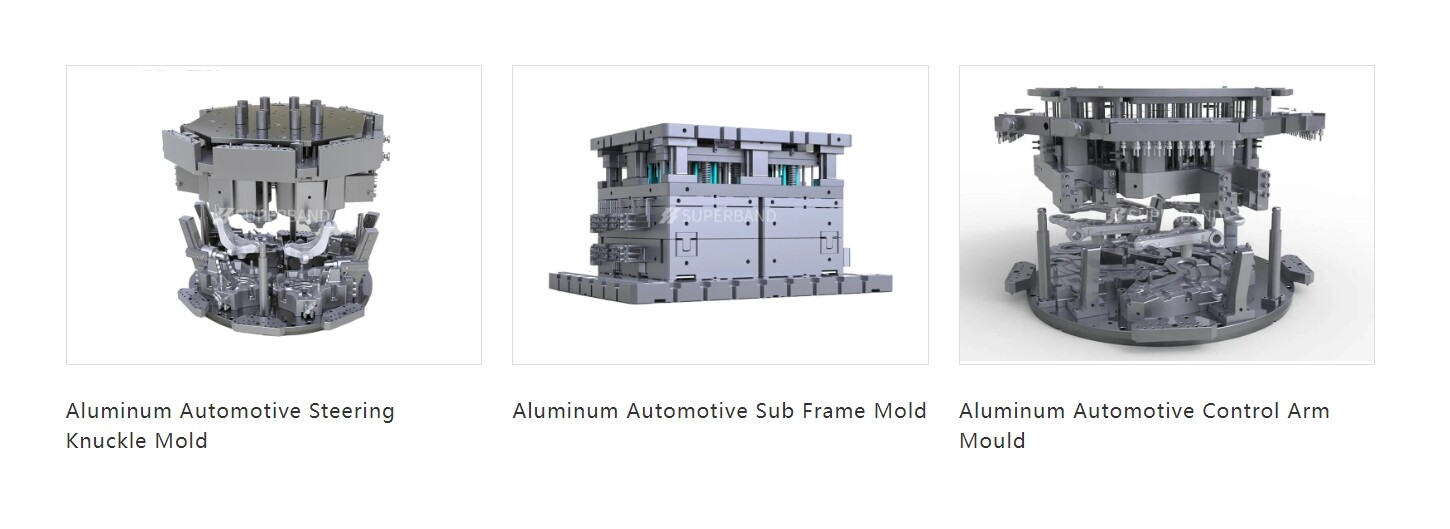

Aluminum molds are well-suited for producing parts with intricate or complex geometries, thanks to their excellent machinability and moldability. The versatility of aluminum molds allows for the production of a wide range of components across various industries, including automotive, consumer electronics, and medical devices.

Aluminum possesses natural corrosion resistance properties, making aluminum molds more resistant to rust and degradation compared to steel molds. The inherent corrosion resistance prolongs the lifespan of aluminum molds and reduces the need for frequent maintenance, resulting in higher operational efficiency and cost savings over time.

Aluminum is a highly recyclable material, and aluminum molds can be recycled at the end of their lifecycle, minimizing waste and reducing environmental impact. Choosing aluminum molds aligns with sustainability goals and demonstrates a commitment to eco-friendly manufacturing practices.

The advantages of using aluminum injection molds are multifaceted, ranging from cost-effectiveness and faster cooling times to improved surface finish and eco-friendliness. By leveraging the unique properties of aluminum, manufacturers can optimize their injection molding processes, enhance product quality, and remain competitive in today's dynamic marketplace.