| Availability: | |

|---|---|

| Quantity: | |

Product Description

With product design & CAE, casting process design, mold design and manufacturing ,mold trial of the whole process technology.

|   |   |  |  |

Process desig | Mold trial | Mold deformation analysis | Mold design and productio | On-site trial production |

Mold Design

We are testing subframe project of average thickness 3.5mm.

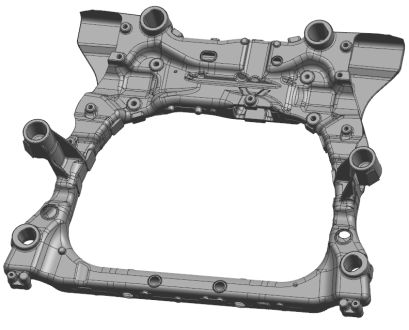

Front Subframe | ||

Product dimension (mm) | Weight (kg) | Average wall thickness(mm) |

1133x971x286 | 24.4 | 3.5 |

Front Subframe | ||

Product dimension (mm) | Weight (kg) | Average wall thickness(mm) |

1188x1080x267 | 22 | 4 |

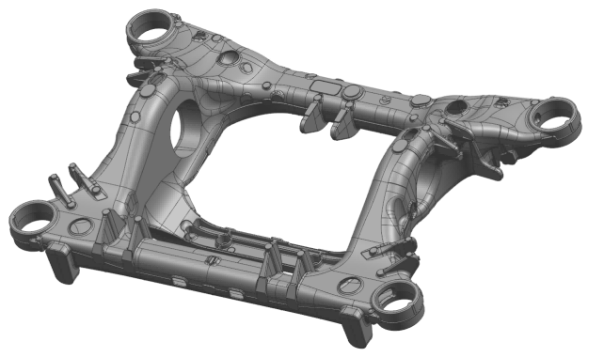

Rear Subframe | ||

Product dimension (mm) | Weight (kg) | Average wall thickness(mm) |

1264x850x327 | 26.2 | 4 |

Mould Making

Superband has hundreds of advanced CNC machining equipment for molds, including DMG, Makino and our own vacuum heat treatment workshop. Applies MES and APS systems to improve the intelligent management level of mold manufacturing and ensure the quality of molds.

Trial Mold

With mold trial capabilities and can provide personalized production process support according to customer needs.

About Us

Cooperation Brand

Served Auto Brand directly or indirectly: Tesla, Ford, VW, BMW, Benze, NIO, BYD, Geely etc, which almost covers all major auto companies.

Hot Tags

Low Pressure Process / LPDC Mould / Subframe Mold / Chassis Structural.

FAQ

Advantage of low-pressure for subframe,knuckle ,control arm :

Low-pressure die casting is a method of production that uses pressure -rather than gravity , to fill molds with molten metal .In this process , the holding furnace located below the cast and the liquid metal forced upwards through to rise tube and into the cavity . The pressure is applied constantly ,sometimes in increasing increments ,to fill the mold and hold the metal in place within the die until it solidifies. Once the cast has solidified , the pressure is released and any residual liquid in the tube or cavity flows back into the holding furnace for recyciling’,when cooled , the cast is simply removed.

A).reduces oxide formation and porosity.

B).Ensuring superior consistency form to to bottom.

C).Exceptional density and strength values.

D).Suitable to automation production.