Views: 0 Author: Site Editor Publish Time: 2025-06-17 Origin: Site

Not all die castings are created equal.High quality die casting means strong, accurate, and reliable parts.In this post, you’ll learn what makes a casting “high quality” and why it matters for safety and cost.

Die casting is a process where molten metal is injected into a steel mold.It uses high pressure to force the liquid into shape quickly.After solidifying, the part is ejected, trimmed, and cooled.This method is used for mass-producing precise metal components.Materials often used include aluminum, zinc, and magnesium.Each offers unique benefits in terms of strength, weight, and corrosion resistance.

| Material | Key Benefits | Common Uses |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Auto, aerospace, electronics |

| Zinc | Excellent detail, low melting pt | Consumer goods, connectors |

| Magnesium | Lightest structural metal | Electronics, medical, auto parts |

High-Pressure Die Casting (HPDC) is the most common method.

Molten metal is injected into a mold at high speed and pressure.

This creates parts with excellent surface finish and tight tolerances.

Low-Pressure Die Casting (LPDC) uses gas pressure to fill the mold slowly.

It’s good for thicker parts that need fewer defects and better mechanical strength.

Gravity Die Casting relies on gravity alone—no pressure is applied.

This method is slower and simpler but better for certain alloys.

| Process | Pressure Level | Surface Finish | Ideal For |

|---|---|---|---|

| HPDC | High (1000+ bar) | Very smooth | Thin-walled, detailed parts |

| LPDC | Low (0.5–1.5 bar) | Good | Structural parts, fewer defects |

| Gravity | None | Moderate | Low-volume, simpler components |

High quality die castings hold tight tolerances—often within ±0.1 mm.

These tight specs reduce the need for secondary machining.

Dimensional checks use tools like CMMs, calipers, and gauges.

Control starts at mold design and continues through every injection cycle.

| Feature | Standard Casting | High Quality Casting |

|---|---|---|

| Typical Tolerance | ±0.5 mm | ±0.1 mm or better |

| Repeatability | Moderate | Very high |

| Measurement Tools | Manual only | CMM, laser, probes |

A smoother finish improves both function and appearance.

High quality parts show fewer tool marks or flashes.

Cosmetic surfaces might not need polishing or coating.

Tool design, die temperature, and alloy choice affect smoothness.

| Surface Grade | Description | Need for Post-Processing |

|---|---|---|

| SPI A1 | Mirror finish | No |

| SPI B3 | Satin/matte | Maybe |

| SPI D3 | Rough texture | Likely |

Great castings resist cracks, warping, and leaks.

HPDC parts achieve pressure tightness with controlled fill and cooling.

Porosity should be minimal—ideally near zero in sealing areas.

Process controls like vacuum assist or squeeze pins improve strength.

Quality checks include pressure tests and X-ray scans.

| Integrity Metric | High Quality Target |

|---|---|

| Pressure Tightness | ≥5 bar (sealed) |

| Internal Porosity | <2% volume |

| Fracture Resistance | High across load zones |

The right alloy boosts casting quality.

Each aluminum grade offers different strength, flow, and corrosion resistance.

ADC12, A380, or AlSi9Cu3 are common in HPDC for balance and fluidity.

Microstructure should be refined and evenly distributed.

Additives and modifiers help control shrinkage or hot tearing.

| Alloy | Key Feature | Ideal Use Case |

|---|---|---|

| ADC12 | High fluidity, corrosion-resistant | Electronics, automotive housings |

| A380 | Strength + dimensional stability | Machinery, pressure parts |

| AlSi9Cu3 | Low shrinkage, good casting flow | Complex thin-walled parts |

The die is where quality starts. Every detail matters.Draft angles help parts release without damage.Wall thickness must stay uniform to avoid distortion.Poor flow paths cause air traps or incomplete fills.Venting lets trapped gases escape before solidification.

| Design Factor | Role in Quality |

|---|---|

| Draft Angles | Easy part ejection |

| Wall Thickness | Avoids warping or sink marks |

| Flow Channels | Prevents short shots |

| Vents | Reduces porosity |

No matter how good the mold is, bad machine settings ruin results.Control metal temperature, injection speed, and pressure curves.Too hot? You get shrinkage. Too cold? You get cold shuts.Real-time automation systems keep everything stable.Sensors monitor pressure, flow, and timing down to the millisecond.

Uneven cooling ruins good castings.

It causes internal stress, warping, and weak zones.

Control cooling rate to maintain mechanical properties across the part.

Use thermal analysis tools to detect hot spots in mold cavities.

A good die design includes cooling channels near problem zones.

| Issue | Cause | Solution |

|---|---|---|

| Hot Spots | Poor heat dissipation | Add internal cooling circuits |

| Shrink Cavities | Uneven solidification | Uniform wall thickness |

| Cracks/Distortion | Thermal stress | Controlled cooling sequences |

Skilled operators make fewer mistakes and spot defects early.

Setup includes die alignment, lubrication, and shot calibration.

Bad alignment or poor lubrication can cause serious flash or wear.

Regular training reduces human error and improves consistency.

Well-maintained machines plus well-trained people equal better castings.

A good mold design prevents many casting defects.

Wrong draft angles cause sticking or tearing during ejection.

Uneven wall thickness leads to warping and incomplete fill.

Improper flow paths trap air and create cold shuts.

Missing venting causes gas entrapment and porosity.

| Design Element | Impact if Done Poorly |

|---|---|

| Draft Angles | Damage during part ejection |

| Wall Thickness | Warping or sink marks |

| Flow Path | Cold shuts, short shots |

| Venting | Gas porosity, incomplete fill |

Die casting isn’t set-and-forget. It needs constant control.Melt and die temperature must stay within tight ranges.Wrong injection speed can trap gas or cause turbulence.Pressure curves should match the mold’s fill needs.Modern systems use real-time monitoring and alarms.Automation helps reduce variability and operator error.

Cooling needs to be even—fast but not too fast.Hot spots cool slower and cause shrinkage porosity.Good thermal balance prevents residual stress and cracks.Use internal cooling lines and thermal inserts when needed.Poor solidification leads to inconsistent strength and density.

Even the best machine fails with a bad setup.Poorly adjusted clamping force causes flash or misalignment.Untrained operators miss signs of early wear or misfill.Maintenance routines reduce breakdowns and part defects.Good training reduces human error and ensures repeatability.

| Operator Task | Risk if Skipped or Poorly Done |

|---|---|

| Mold Setup | Misalignment, parting line flash |

| Machine Calibration | Inconsistent pressure or speed |

| Routine Checks | Unnoticed leaks, wear, or cracks |

| Training | Errors in injection or trimming |

The first step is always a good look.

Inspectors check for surface defects—cracks, cold shuts, blisters, or flash.

They also watch for mold misalignments, discoloration, or incomplete fills.

This step is fast, non-invasive, and cost-effective.

| Visual Defect | What It Means |

|---|---|

| Cold Shut | Poor metal flow or low temp |

| Flash | Excess metal at parting line |

| Porosity spots | Entrapped air during injection |

| Cracks | Cooling stress or brittle areas |

Precision parts need tight dimensions.

Coordinate Measuring Machines (CMMs) measure castings in 3D space.

These tools compare the actual casting to the CAD model.

Manual tools like calipers and gauges help spot check basic features.

Some companies use laser scanning for quick, full-surface mapping.

| Tool | Use Case |

|---|---|

| CMM | Full 3D dimensional checks |

| Calipers/Micrometers | Fast verification of key points |

| Laser Scanner | Surface profile and geometry |

Some defects hide inside the part.

X-ray inspection helps find internal porosity or shrinkage voids.

CT scanning gives detailed 3D imaging for complex internal analysis.

Ultrasonic testing detects cracks or gaps using sound waves.

Dye penetrant testing helps find open surface cracks invisible to the eye.

| NDT Method | Best For |

|---|---|

| X-Ray | Internal voids and porosity |

| CT Scan | Complex internal geometries |

| Ultrasonic | Sub-surface cracks |

| Dye Penetrant | Surface-breaking flaws |

Some castings must hold air, oil, or coolant.

For these, leak testing is a must.

Air pressure tests fill the part with pressurized air, then monitor for drops.

Helium or vacuum testing finds ultra-small leaks in sensitive parts.

Hydraulic pressure checks apply fluid to test sealing strength.

These tests are common for engine parts, valves, and housings.

| Test Type | What It Verifies |

|---|---|

| Air Pressure | Basic leak integrity |

| Vacuum Testing | Microscopic leaks in sealed units |

| Hydraulic Test | Strength under operating pressure |

Your design directly impacts casting quality—every line, edge, and wall matters.

Thin walls cool fast but may cause distortion. Sharp corners trap air and raise porosity risk.

Involve die casting experts early. They help optimize draft angles, gate placement, and wall thickness.

This reduces defects and avoids costly mold changes later.

| DFM Element | Why It Matters |

|---|---|

| Wall thickness | Even walls prevent shrinkage defects |

| Draft angle | Eases ejection and reduces surface drag |

| Radiused corners | Improves metal flow |

| Gate and runner | Controls flow speed and pressure |

Not all alloys behave the same under pressure and heat.

Aluminum alloys like A380 or ADC12 are popular for strength, flowability, and corrosion resistance.

Need strength and pressure tightness? Use vacuum-assisted HPDC. Need simple parts? Gravity casting may work.

Choose based on:

Operating temperature

Load-bearing needs

Surface requirements

Machinability or post-processing

Matching alloy and casting method saves rework, improves yield, and boosts long-term performance.

Don’t just look at price—check how your supplier ensures quality.

Ask about inspection tools, sampling rates, and corrective action systems.

Require documented quality control processes. ISO 9001 and IATF 16949 are key certifications.

Also ask for:

PPAP (Production Part Approval Process)

FMEA (Failure Mode and Effects Analysis)

Material traceability records

| Certification / System | Why It Matters |

|---|---|

| ISO 9001 | General quality management |

| IATF 16949 | Automotive quality requirements |

| PPAP | Proves production readiness |

| FMEA | Identifies and reduces process risk |

Not all die castings are created equal. Some are built for basic form, others for flawless function.

The difference lies in precision, consistency, and end-use performance.

Let’s break down how standard and high quality die castings compare across key features:

| Feature | Standard Die Casting | High Quality Die Casting |

|---|---|---|

| Tolerance | ±0.5 mm typical | ±0.1 mm or better |

| Surface Finish | Often rough, needs machining | Often usable as-cast, smooth finish |

| Porosity | Acceptable in non-critical zones | Minimized, especially in sealing areas |

| Inspection | Basic visual checks | Dimensional + Non-Destructive Testing |

| Lifecycle Cost | Lower upfront | Fewer failures, lower long-term cost |

Standard parts allow more variation. High quality castings hold much tighter tolerances.This reduces the need for extra machining.

Standard parts may need grinding or coating. High quality ones often ship ready-to-assemble.That saves both time and cost downstream.

Standard castings may contain small air pockets. For high quality, porosity is controlled or removed.This ensures pressure tightness and strength.

Standard checks are mostly visual. High quality adds CMM, X-ray, and pressure testing.You know exactly what you're getting.

Standard parts may cost less at first. But defects, failures, and rework can add up fast.High quality parts lower long-term cost by lasting longer and performing better.

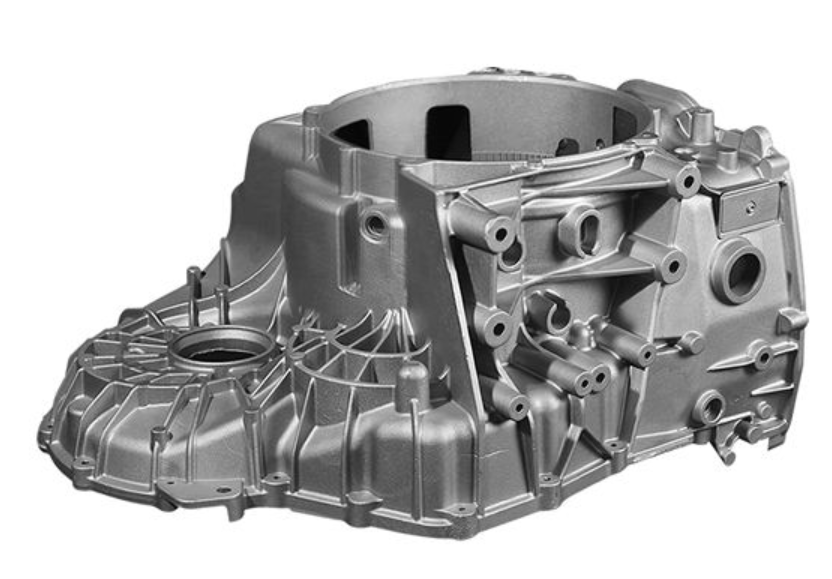

If a part faces constant pressure, motion, or load, don’t compromise.Think of engine blocks, gear housings, or hydraulic components.These need tight tolerances and no porosity to work safely.Even small flaws can lead to fatigue or cracks over time.High-quality die casting ensures performance under real-world stress.

| Application Type | Quality Requirement |

|---|---|

| Engine or transmission | High strength + sealing |

| Structural connectors | Zero porosity |

| Moving assemblies | Precise tolerance fit |

If the part is visible to the end user, looks matter.Consumer electronics, lighting fixtures, or medical housings must appear flawless.Surface finish, edge definition, and uniformity affect how people see your product.Bad casting? It reflects poorly on your brand, even if the part works fine.High-quality casting ensures your design looks as good as it functions.

| Industry | Why Appearance Matters |

|---|---|

| Consumer tech | Visual appeal builds trust |

| Medical devices | Clean finish shows reliability |

| Automotive trim | Reflects overall brand quality |

Cutting corners upfront often costs more later.

Poor-quality casting leads to more scrap, rework, and product returns.

It also causes unexpected failures in the field—costing you time and reputation.

Spending more for higher quality often means lower total cost per unit.

Especially in high-volume production, small defect rates add up quickly.

| Cost Factor | Low Quality | High Quality |

|---|---|---|

| Scrap Rate | High | Low |

| Customer Complaints | Frequent | Rare |

| Maintenance | Often required | Less frequent |

Start with certifications. Look for ISO 9001, IATF 16949, or other quality system approvals.

Visit the facility if possible. A clean, organized factory says a lot.

Ask about technical support. Can they help with design and material selection?

They should also run regular quality audits to ensure consistency and reliability.

| Key Quality Indicators | Why It Matters |

|---|---|

| ISO/IATF Certification | Ensures standard quality systems |

| Clean Facility | Reflects attention to process control |

| In-House Engineering | Helps optimize part design |

| Audit Documentation | Confirms quality tracking |

Don’t just ask about capabilities—ask about results.

What is your average defect rate?

How do you handle porosity or dimensional variation?

What non-destructive tests do you perform?

Can you share case studies or references?

The more specific the answers, the more reliable the supplier.

Watch for inconsistent pricing without clear breakdowns.

Be cautious if they can’t explain their quality processes.

Avoid suppliers with no documented inspection reports.

If there’s no post-casting support, you may face delays and cost overruns later.

| Red Flag | What It Could Mean |

|---|---|

| No certifications | Lack of quality control |

| No inspection reports | Unverified product quality |

| Poor communication | Delays and misunderstandings ahead |

| No support after delivery | Risk of unresolved issues |

High quality die casting means strong, precise, and consistent parts.It takes the right process, materials, and skilled people.Choose based on your design, function, and performance needs.

A: It means precise dimensions, smooth surfaces, durable structure, and few or no defects.

A: Upfront, yes. But it saves money long-term by reducing waste, rework, and failures.

A: Absolutely, especially with HPDC, quality alloys, and strong process control.