2022-09-29

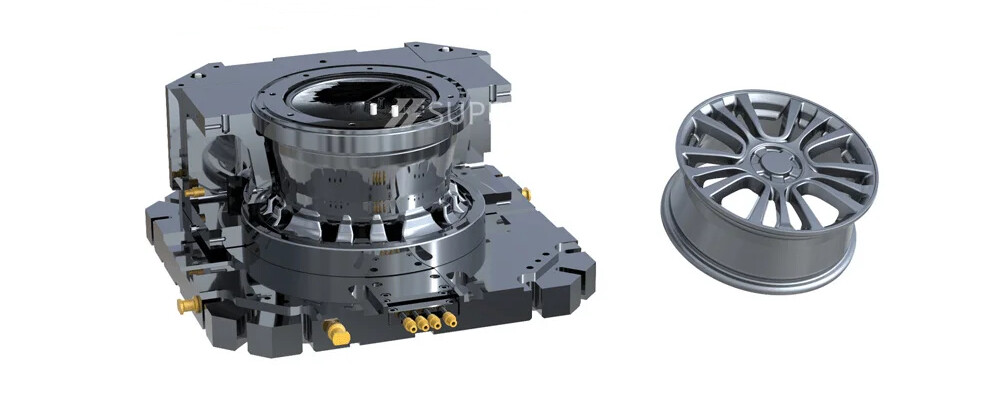

Low-pressure die casting(LPDC) is one of the die casting processes. The automotive industry is a major user of low-pressure die-casting, mostly for the production of aluminum castings, such as aluminum alloy wheels.

Aluminum is one of the most common die casting materials, and its high tensile strength is one of the advantages of finished aluminum castings. In addition, low pressure die casting parts have more surface treatment options and are more aesthetically pleasing than other non-ferrous materials.

Low pressure die casting refers to the injection of molten material into a die casting under pressure. The liquid metal is forced up into the cavity in the process, applying constant pressure to fill the mold and hold the metal inside the mold until the liquid metal solidifies. After cooling, the die casting mold is removed and low pressure die casting parts are obtained.

The low pressure casting production process includes the following staple processes:

● Metal melting

● Preparation of die-casting molds or castings

● Preparation before pouring (sealing test, mold matching, mold tightening, etc.)

● Pouring (injecting metal liquid, solidifying and cooling, etc.)

● Demoulding and removal of low pressure die castings

Low-pressure die casting typically uses small pressures around 20-100 kPa. In the die casting process, pressure holds the metal in the mold until the liquid metal solidifies into the casting. Pressure and speed can be adjusted in most cases, and are suitable for casting various alloys and castings of various sizes.

With numerous advantages, the low-pressure die casting process is well suited for automated production. Compared to other casting methods, low-pressure die casting has the following benefits:

● High casting quality and dimensional accuracy

● Quality surface finish, high strength, and hardness

● Die casting of complex castings and long die life

● Easy to mechanize and automate

● Small processing volume or direct use without mechanical processing generally improves metal utilization and reduces processing equipment and man-hours

Low-pressure casting is mainly used to produce aluminum alloys and magnesium alloy parts, such as automobile wheel hubs in the automotive industry, automotive engine brackets, cylinder heads, and other castings with complex shapes and quality requirements.

Low-pressure casting can also be applied to small copper alloy castings, such as plumbing fittings, faucets in bathrooms, and more.

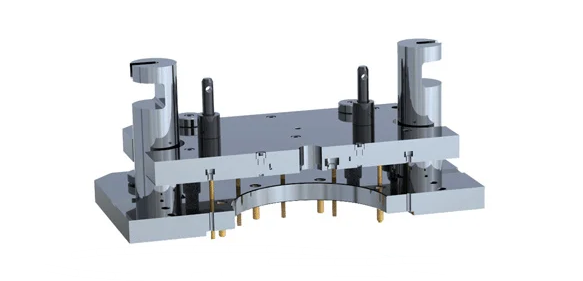

All custom low-pressure die casting mold designs start with a consultation. Learn about the LPDC wheel mold tool, LPDC wheel mold quality, LPDC wheel mold detail, LPDC wheel mold application, and more at Superband.

In either case, for selection or maintenance, we welcome you to contact us at Superband to assist you in the decision-making process.